In stock

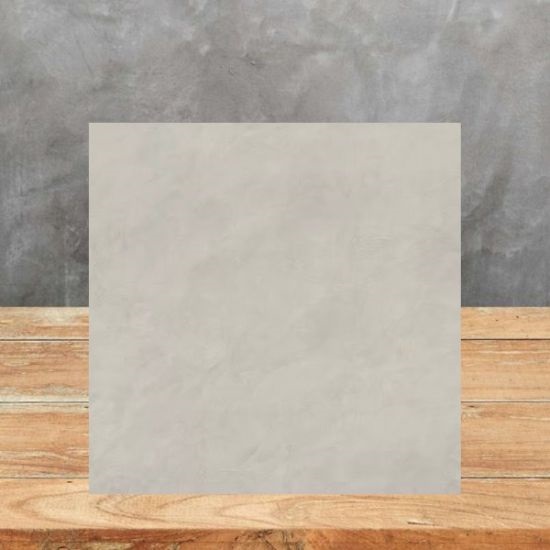

Dekton Argentium

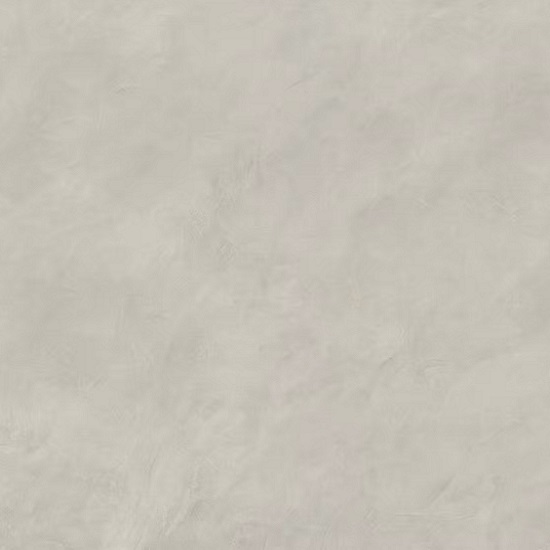

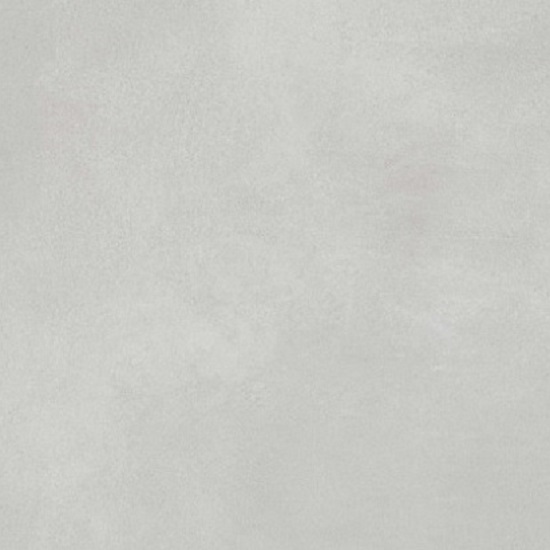

Our Dekton Argentium worktop offers natural silvery colours that replicate the organic beauty of fine plaster. You can use this gorgeously textured kitchen and bathroom worktops as a focal design separately or combine it with other materials to create a spectacular plaster effect in various thicknesses and sizes. Read More

Our Dekton Argentium worktop offers natural silvery colours that replicate the organic beauty of fine plaster. You can use this gorgeously textured kitchen and bathroom worktops as a focal design separately or combine it with other materials to create a spectacular plaster effect in various thicknesses and sizes.

Argentium elegantly displays the most delicate ultra-compact porcelain surface in a smooth matte worktop with complete body colouring. It is the perfect material when you want to create a smooth transition from your kitchen to outdoor gardens.

Argentium Description: Textured, Non-porous Plaster

Did you know that authentic Argentium silver alloys contain over 90% pure silver, which makes them tarnish-resistant? -And Unlike other metallic surfaces, Argentium by Dekton does not rust over time.

Plaster is one of the most prominent building materials because it offers a continuous minimalistic surface with a 100% natural look. And with Dekton Argentium, you can have an extra-large light grey plaster-effect porcelain worktop you can choose in four thicknesses, creating a bridge between the old and modern.

While the colour is homogeneous, the stone has a tactile feel and similar aesthetic features to concrete, lending a serene ambience to your kitchen and bathrooms.

Dekton Argentium Worktops: high performance, low weight

Dekton Argentium comprises raw materials that are crushed, pressed and heated to result in a sintered stone. Sintering is a sped-up variant of natural stones’ changes over millennia, industrially reduced by only forty-eight hours. Cosentino uses heat and pressure to compress and produce the solid ultracompact worktop material with several benefits.

A Dekton countertop provides advantages over other worktop materials such as quartz, marble and granite. In addition, the slabs undergo treatment during the production process to offer advanced stain-resistant nanotechnology, UV rays protection, water resistance, impact resistance, and heat resistance.

Our Argentium ultracompact surface has outstanding finishing, long-lasting endurance, and stunning looks. Indeed, this kitchen worktop’s feel and visual experience evoke the beauty of natural marble.

Sustainable Worktops with Lots of Love and Fewer Worries

Argentium is part of this collection of work surfaces that boasts the International EPD System (International Environmental Product Declaration), which evaluates greenhouse gas emissions, the efficiency in the consumption of raw materials and energy, and the reduction in waste it generates.

In addition, Dekton products achieved the status of being Carbon Neutral materials goal of the SDGs of Agenda 2030 for Sustainable Development.

Dekton Argentium Sizes, Thicknesses & Finishes

- Slab Size: Dekton’s huge slab size of 3,200 x 1,400 mm covers many areas, minimising the number of joints. In addition, it makes the entire design and installation procedure more efficient and less expensive in terms of installation material usage and effort during its installation. Finally, it includes maintenance, replacement, and restoration. For example, worktop suppliers must be more careful with grouts and edges when dealing with small panels—also, having smaller stone pieces mean cuts, more edges to polish, and, ultimately, more upkeep. With Argentium, you will forget about all of these nuances.

- No Joints: Similarly, full-size Dekton slabs require cutting, cleaning, maintenance work, and steps to increase physical attractiveness. Designers have the opportunity to incorporate natural beauty into these essential pieces in a consistent way by eliminating joints and seams. The large stone slabs have beautiful veins, fissures, and patterns best appreciated on a single part of the Dekton slab cut from a single sheet.

- Thicknesses: The stone countertop brand lets you choose from the highest number of thickness options. You can select Dekton Argentium from thicknesses of 0.4 cm, 0.8 cm, 1. 2 cm and 2 cm.

- Finish: Dekton Argentium belongs to the Kraftizen Collection and is available in Matte, a smooth finish that adds a delicate, elegant appearance to the worktop.

Dekton Argentium Advantages

- Durability: Dekton does not eventually fade, and the colour is permanent.

- Large Sizes: Its large slab sizes maximise material use whilst reducing the number of joints on your project.

- Non-Porous: it does not absorb any liquids, making it ideal for continuous contact with water areas.

- Easy to Clean: Use warm water and soap to clean.

- Stain-Resistant: Resistant to vinegar, soy sauce, ketchup, coffee, oil, wine, abrasive acids, oils, etc.

- Scratch-Resistant: Dekton boasts the highest rating in tests for scratch resistance of its surface.

- High-Heat Resistant: it can tolerate up to 300 Celsius without cracking, burning or scorching.

Caring for the lightest, strongest Dekton Worktop

Dekton is a 100% chemical and stain-resistant surface making it the perfect kitchen worktop. For daily cleaning, use a glass-cleaning spray.

Then, dry with a paper towel or cloth.

Dekton Cleaning & Getting Rid of Tough Stains

- The matte finish is unaffected by any household substance or chemical, making it extremely difficult to stain.

- The polished finish may stain only when in contact for over 24 hours with a strongly coloured, abrasive, or sticky chemical. In these situations, you can use cream detergents with abrasive particles (i.e. CIF Cream) or solvents (i.e.) acetone or universal solvent).

Dekton Manufacturing

The Dekton Argentium making process entails 7 (seven) key stages during its production:

- Quality Control: First, the company examines the raw materials for quality and usability. To avoid cross-contamination, the manufacturer keeps all the natural ingredients separately. Then, it moves these materials onto hoppers and purification machines with a conveyor belt.

- Mixing Raw Ingredients: The manufacturer transfers the formula from the hoppers or purification systems to a moist grinding process. It blends the different raw ingredients precisely and ground to specific particle sizes. The particle size entirely controls the pace and direction of the chemical process that produces DEKTON. It also influences the product’s ultimate qualities. Following a specific stabilisation time, this combination is kept separately before application.

- Pigmentation: The company uses a sophisticated mixer, diluters, and stirrers during the pigmentation process. Dependent on the colour or finish, this technology can blend inorganic colours with the remainder of the DEKTON composition. Because these pigments are also a component of the material’s chemical process, chemical quality control is comprehensive and demanding.

- Atomisation: the manufacturer atomises and dries the previously coloured formula until it achieves a particular size, grain shape, and humidity. Then, it keeps the numerous powder products in separate silos. In this scenario, humidity regulates these tiny particles’ liquidity, thus depositing in the several receptacles that supply the future decorative surfaces. These travel between the channels that provide other decoration components or allow them to move during blending systems.

Decorating the Versatile and Powerful Dekton

- Decoration of the slabs: These nanoparticles are carefully positioned in multiple places on a belt, forming a continuous slab, employing several unique processes for their design and function. The manufacturer creates various aesthetic impacts using these decorating systems. The company can create different effects throughout the slab’s thickness or only on its surface. In all, and during the initial production stage, 16 separate ornamental systems can function independently, together, or in groupings, resulting in an extraordinary creative variety of materials.

- Shaping Dekton: manufacturer divides the continuous slab into various portions that will ultimately be combined to form the final slab, which the brand exposes to an intense ultra-compaction procedure. Cosentino uses a one-of-a-kind press with particular sizes and global compacting capabilities to accomplish this.

- Thermal process: the manufacturer gives the slab its ultimate physical, chemical, and aesthetic qualities during this stage. It uses up to 1300 Celsius temperatures, ensuring that the different coloured particles respond consistently. Then, the brand converts the raw material and pigments into other transitory composites. Finally, the process regulates these composites using heat to react and take the correct synthesis process.

Want to know more about Dekton Argentium as worktops, walls and floors?

7 Advantages of Dekton Argentium Countertops

Dekton possesses all of the technical criteria necessary to change any interior or outdoor residential design concept to a highly resistant surface.

- Wide Range of Colours: there are fifty different Dekton colours across seven Collections. Dekton's Collections encompass an unlimited number of colour, finish and thickness combinations that you can use anywhere. In addition, the seven Dekton collections cover every design style and theme: Natural, Tech, Solid, Industrial, Liquid, and Stonika.

- Scratch and Abrasion Resistant: the surface comprises 116 mm3 wear volume average abrasion. According to a study about the abrasion wear of natural stones, Dekton provides almost 5.5 times abrasion resistance than white marble, which offers abrasion wear of 22.23.

- Unrivalled Thermal Shock Resistance: natural stones such as marble, granite and quartzite can crack if you place a scorching item when the surface is at cool temperatures. It is because of the shock in changing temperatures between the surface's temperature and the things you are putting on it. But placing sweltering items on manufactured stones such as quartz will burn the resin on the surface, leaving unrepairable scorching. In contrast to all the stones mentioned above, high temperatures do not affect Dekton's surface. You can drag your pans and pots from the oven directly onto Dekton, which withstands up to 300 Celsius degrees of heat.

- Fireproof: Dekton is rated Class A1 (Class A1 has the highest performance and class F has the lowest), according to the UK's BS EN 13501-1 regulation, offering the highest performance regarding reaction to fire. It also means that, unlike many other stones, it can tolerate direct contact with heated cookware, devices, and cutlery without being burned.

- Easy to Clean: Dekton isn't affected by bleach compared to quartz. And, unlike marble, it isn't affected by acids. Instead, spray the surface with any typical household and cleaning chemical. Dekton is perfect for quick clean-ups around the kitchen and bathroom.

- Low Maintenace: it doesn't require sealants, additional coatings, primers, or enhancers. Ever. Over time, this surface's technical features save you more time and cost than any other worktop material due to its next-to-no-maintenance attributes.

- Stain Resistant: It can withstand any cooking ingredient, food and substance, including wine, turmeric, coffee, lemons, ketchup, etc. For the daily cleaning of DEKTON by Cosentino, use Windowlene or a similar spray and a soft scouring pad. Otherwise, use water and neutral soap.

Five Additional Dekton Benefits

As a bonus, by choosing a Dekton work surface for your home and offices, you will instantly benefit from five design Extras:

- Dimensional Stability: working with the set Dekton slab sizes of 3200 x 1440 mm allows you and everyone else in your project to plan months before work on site commences, avoiding material waste and saving costs. In addition, because it expands minimally, you can fit it with narrow seams between worktops.

- In all situations, the joints will maintain their minimal thickness.

- High Mechanical Strength: The strength of the press used to create Dekton is up to 25,000 tonnes, equivalent to 111 Statues of Liberty, giving it the highest mechanical power in its class. Its compactness makes it available in five different thicknesses, letting you use it even when your space needs protection from impact and winds.

- UV (ultraviolet) light resistance is excellent: Dekton is extremely UV resistant and does not fade or deteriorate over time in any interior or outdoor application.

- High Resistance to Hydrolysis: It isa process that controls when and to what extent the surface disintegrates. Hydrolysis is another term for the surface splitting of cheaper materials. Dekton's superior resistance is ideal for bathroom applications, spas, or outdoor pools and ponds.

- Resistant to Freezing and Thawing: The ability to withstand freezing and thawing: Dekton resistance against thawing and freezing tests (UNE EN ISO 10545-12), and its use in diverse weathers demonstrate its outstanding performance.

CHEMICAL FORMULATION

Because this stone contains no resins or organic ingredients, Dekton does not employ a polymerisation process during its manufacture, and its chemical makeup is entirely inorganic.

In addition, DEKTON uses several formulas that vary according to the surface type, meaning that the final chemical structure can change without affecting its chemical or physical qualities.

Aluminium silicates, amorphous silica, crystalline silica, zircon, and inorganic colours are a few examples of DEKTON's chemical makeup. The crystalline silica component in all colours and formulations are always less than 11% by weight.

TECHNICAL CHARACTERISTICS

| TEST | STANDARD | DETERMINATION | Units | Family i | Family ii | Family iii |

|---|---|---|---|---|---|---|

| Flexural and bending strength | UNE EN ISO 10545-4 | Average flexural strength |

N |

60 | 67 | 59 |

| UNE EN ISO 10545-4 | Average bending load | N | 2.548 | 2.313 | 2.356 | |

| UNE EN ISO 10545-4 | Average bending strength | % | 14.966 | 13.559 | 13.818 | |

| Water absorption, open porosity and densities | UNE EN ISO 10545-3 |

Boiled water absorption |

% |

0 |

0,1 |

0,1 |

| UNE EN ISO 10545-3 | Vacuum water absorption | % | 0,1 | 0,1 | 0,1 | |

| UNE EN ISO 10545-3 | Open porosity | % | 0,2 | 0,2 | 0,2 | |

| UNE EN ISO 10545-3 | Apparent relative density | g/cm | 2,51 | 2,61 | 2,53 | |

| UNE EN ISO 10545-3 | Apparent density | g/cm | 2,50 | 2,61 | 2,52 | |

| Resistance to deep abrasion | UNE EN ISO 10545-6 | Abrasive volume | mm3 | 125 | 106 | 115 |

| Determination of dimensions and surface aspect | UNE EN ISO 10545-5 C | Coefficient of average restitution | - | 0.85 | 0.85 | 0.85 |

| Determination of thermal linear dilation | UNE EN ISO 10545-8 | Dilatation between 30-100ºC | ºC-1 | 6,5. 10-6 | 5,1. 10-6 | 0,3. 10-6 |

| Determination of thermal shock resistance | UNE EN ISO 10545-9 | Damage | - | Approved / undamaged | Approved / undamaged | Approved / undamaged |

| Determination of humidity dilation | UNE EN ISO 10545-10 | Maximum expansion | mm/m | 0.1 | 0.1 | 0.1 |

| Average expansion | mm/m | 0.0 | 0.0 | 0.0 | ||

| Determination of freeze resistance | UNE EN ISO 10545-12 | Damage | - | Approved / undamaged | Approved / undamaged | Approved / undamaged |

| Determination of chemical resistance | UNE EN ISO 10545-13 | ClNH4 / Cleaning products | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) |

| Bleach / Salts for pools | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| HCl (3% v/v) | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| Citric Acid (100 g/l) | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| KOH (30 g/l) | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| HCl (18%) | Class | UA (undamaged | UA (undamaged | UA (undamaged | ||

| Lactic Acid (5%) | Class | UA (undamaged | UA (undamaged | UA (undamaged | ||

| KOH (100 g/l) | Class | UA (undamaged | UA (undamaged | UA (undamaged | ||

| Determination of stain resistance | UNE EN ISO 10545-14 | Agente green | Class | 5 | 5 | 5 |

| Agente red | Class | - | - | - | ||

| Iodine (solution) | Class | 5 | 5 | 5 | ||

| Olive Oil | Class | 5 | 5 | 5 |

TECHNICAL SPECIFICATIONS

| TEST | STANDARD | DETERMINATION | UD | Family i | Family ii |

|---|---|---|---|---|---|

| Moisture expansion | ASTM C370 | Average moisture expansion | % | 0.02 | 0.005 |

| Breaking strength | ASTM C648 | Average breaking strength | Ibf | 3963 | 4896 |

| Flexural properties | ASTM C674 | Average modulus of rupture | psi | 10828 | 13997 |

| Water absorption, bulk density, apparent porosity and apparent specific gravity | ASTM C373 | Average water absorption | % | 0.03 (Impervious) | 0.05 (Impervious) |

| Static coefficient of friction (skid resistance) | ASTM C1028 | Static coeficient. Friction dry | - | 0.80 | 0.77 |

| Static coeficient. Friction wet | - | 0.66 | 0.56 | ||

| Wet dynamic coefficient of friction (DCOF) | ANSI A126.1 section 9.6.1 | Average DCOF | - | 0.57 | |

| Relative resistance to wear (Taber abrasion) | ASTM C501 | Average Abrasive Wear Index | 182.2 | 337 | |

| Thermal shock resistance | ASTM C484 | Defects | No Defects | No Defects | |

| Bond strength | ASTM C482 | Average bond strength | psi | 423 | 437 |

| Resistance to chemical substances | ASTM C650 | Common Household and cleaning chemicals | % | ||

| Acetic acid, 3% (v/v) | - | Not affected | Not affected | ||

| Acetic acid, 10% (v/v) | - | Not affected | Not affected | ||

| Ammonium chloride, 100 g/L | - | Not affected | Not affected | ||

| Citric acid solution, 30 g/L | - | Not affected | Not affected | ||

| Citric acid solution, 100 g/L | - | Not affected | Not affected | ||

| Lactic acid, 5% (v/v) | - | Not affected | Not affected | ||

| Phosphoric acid, 3% (v/v) | - | Not affected | Not affected | ||

| Phosphoric acid, 10% (v/v) | - | Not affected | Not affected | ||

| Sulfamic Acid, 30 g/L | - | Not affected | Not affected | ||

| Sulfamic Acid, 100 g/L | - | Not affected | Not affected | ||

| Swimming pool chemicals | - | Not affected | Not affected | ||

| Sodium hypochlorite solution, 20 mg/L | - | Not affected | Not affected | ||

| Acids and bases | |||||

| Hydrochloric acid solution, 3% (v/v) | - | Not affected | Not affected | ||

| Hydrochloric acid solution, 18% (v/v) | - | Not affected | Not affected | ||

| Potassium hydroxide, 30 g/L | - | Not affected | Not affected | ||

| Potassium hydroxide, 100 g/L | - | Not affected | Not affected | ||

| Absorption and bulk gravity | ASTM C97 | Average weight per cent absorption | % | 0,02 | 0,04 |

| Average density | Ib/f | 156 | 160,63 | ||

| Modulus of rupture | ASTM C99 | Average modulus of dry rupture conditions | psi | 8128 | 9042 |

| Average modulus of rupture wet conditions | psi | 7490 | 8446 | ||

| Flexural strength | ASTM C880 | Average flexural strength dry conditions | psi | 6840 | 3118 |

| Average flexural strength in wet conditions | psi | 6205 | 4187 | ||

| Compressive strength | ASTM C170 | Average compressive strength dry conditions | psi | 34409 | >55000 |

| Average compressive strength wet conditions | psi | 17823 | >55000 | ||

| Abrasion resistance | ASTM C1353 | AverageAbrasion Index | - | 349 | 349,48 |

SLIP RESISTANCE REPORT

According to STANDARD EN -14.631Family I (Spectra, Domoos, Sirius, Sirocco, Kadum, Strato, Keranium, Ananké)

| Finish | NATURAL | NATURAL | SLATE | SLATE | WOOD | WOOD | POLISHED | POLISHED |

| Colour | PDomoos / Strato / Sirocco / Kadum / Keranium | PDomoos / Strato / Sirocco / Kadum / Keranium | Sirius | Sirius | Ananké | Ananké | Spectra | Spectra |

| Determination | PSRV dry | PSRV wet | PSRV dry | PSRV wet | PSRV dry | PSRV wet | PSRV dry | PSRV wet |

| Value | 48 | 23 | 49 | 22 | 44 | 21 | Pending Test | Pending Test |

COLOUR AND TONES

Cosentino assigns numbers to describe tones in the colours (slight changes in colour intensity), and each slab is defined by Colour & Tone.

Here are the factors that determine Dekton colours and tone variation:

- Colours in solids: E variant (control with) The slab unit label with Colour and Tone Code reflects the colour and tone.

- The label determines the slab's Tracing and its history. As it progresses through the industrial manufacturing operation via the slab number (batch).

- Spectrophotometer settings: Lab/D65/10o).

- Colours with veins: visible differences (of pattern)

Dekton: 25-year warranty

Besides technical superiority, originality, and style, Dekton offers a 25-year warranty on its designs.

You need to provide your invoice/receipt when filling out the Dekton warranty form within 6 (six) months of your purchase to activate your warranty.

If you don't activate your warranty within this period, you will enjoy the same benefits for 2 (two) years.

Dekton is made from a unique combination of crushed quartz stone, porcelain, and glass and a formula of exclusive raw materials. These natural ingredients are fused and compacted with an industrial press to form a solid and ultracompact stone slab.

Have you got 5 minutes? -The below video shows you the whole Dekton manufacturing process, including its 9 (nine) key steps of production:

These are the four main steps for Dekton cutting:

-

Remove at least 2 cm of DEKTON® slabs from each length.

-

Plan a proper operating sequence that includes first detaching the worktops or entire sections from the slabs and then drilling the required holes.

-

All parts with corners must provide a radius of at least 5 mm (using, for example, an 8 mm drill) to ensure the surface's faultless integrity throughout handling, fitting, and usage.

-

The cutting board should be sturdy and stable. - It must be completely flat and level (you can improve the quality using a wooden, sandstone, cement, or rubber surface to buffer the blade's vibration)

Suggested cutting speeds for DEKTON blades:

-

1 – 1.5 m/min* for 0.8 cm slabs

-

1 – 1.5 m/min* for 1.2 cm slabs

-

0.5 – 1 m/min* for 2 cm slabs

-

0.5 m/min* for 3 cm slabs

DEKTON's distinct chemical makeup and characteristics need specialized techniques and technology. Therefore, before commencing to cut Dekton, it is good to ask for recommendations about tools, conditions, and trade brands.

The below video shows you the full Dekton cutting process:

To install Dekton, you must first ensure that the surfaces are clean. After that, you can use acetone and soap. Then, you must ensure that the substrate (kitchen cabinets, bathroom units, etc.) is level and flat.

Reinforce the worktop's weakest points (the cutouts) as needed.

First, carefully place the panels over the cabinets during installation, ensuring the seams fit perfectly. Then, with the pieces in place, lift each panel and fix them with adhesive. You can make adjustments to the parts outdoors to avoid dust spreading. Finally, remove any glue and silicone excess with acetone and soap.

The below video shows an entire Dekton worktop installation by Cosentino:

Dekton is virtually stain-proof, and quartz is stain-resistant. Whilst quartz may stain with bleach and turmeric, Dekton does not. Dekton can withstand temperatures of up to 300 Celsius, and quartz tolerates up to 150 Celsius degrees. Dekton does not discolour when you expose it to direct sunlight for long periods, but quartz does.

Dekton is more rigid than quartz, making it more prone to edge chipping.

Dekton offers effortless and negligible maintenance. Clean Dekton using warm water, soap, and a sponge. Then, dry with a paper or towel cloth. If needed, use a window cleaning spray (for example, Windowlene) or ph balanced soap.

Dekton worktops usually cost slightly more than quartz, typical granite, and marble. Nonetheless, Dekton is priced similarly to other popular worktop materials, starting at £169 per square metre. However, final prices vary according to the worktops' features, edge type, and the site's location and accessibility.

Even though Dekton initially costs more than typical natural stones (rare granite, quartzite, or marble cost more than Dekton), it doesn't require maintenance. It is a crucial factor because it makes Dekton very cost-efficient over time. In addition, it offers a 25-year available warranty that you can transfer to the home buyers when you sell the property, helping raise its overall value.

Even though Dekton materials costs are similar to high-quality quartz, manufacturing and handling are more time-consuming. Dekton is an ultracompact, solid surface that requires specific tooling for cutting and additional care to handle. Its toughness requires twice as much fabrication time compared to softer materials such as marble or quartz.

It is tough to scratch Dekton. For example, lobbies and high-traffic areas are the most demanding areas for decorative surface applications, requiring a minimum Ha of 12, according to the ASTM 501 test. And Dekton offers an average relative resistance to wear of 350.5 within this internationally used index.

No. But even though the possibilities of chipping Dekton are inferior to other surface products, it is more rigid than quartz, granite, and marble, making it more prone to chipping than most types of the mentioned materials.

If you live in London or up to 100 miles from it, you can get Dekton samples here. The team at the Worktop Library will get Dekton samples delivered to your door between 2-3 business days.

Dekton is made in Cantoria, a municipality in the Almeria province of Spain's autonomous community of Andalusia.

Dekton is a magnificent material for fire hearth and chimney external cladding applications because of its linear thermal expansion of: 5.1 and 6.5. 10⁻⁶ • ºC⁻1, allowing you to keep a minimal number of joints.

You can use Dekton on the front or side of chimneys, isolated from the heat by an internal resistive wall. However, the manufacturer doesn't recommend its use within ducts due to the possibility of sudden changing conditions and temperatures.

RETURNS AND SHIPPING POLICY RETURNS

Except for damaged surfaces, all sales are final. Please call 020 39760029 or email [email protected] for more information before mailing exchanges or online purchasing return products installed in faulty or damaged condition.

SHIPPING \ TURNAROUND

We process all orders within one business day. However, please remember that specific stones may have longer lead times due to high demand or special-order items from other countries.

DELIVERY & INSTALLATION COSTS

We compute delivery and installation costs at the time of purchase. Our team of professional stone fitters install all stone surfaces.

Installation and delivery charges vary depending on weight, site access, and delivery location from our workshop in West London, United Kingdom.

INSTALLATION & DELIVERY ADDRESSES

Stone worktop installation is available in London and 150 miles of surrounding areas. Please contact our Worktop Library Service Team at (20) 39760029.

Reviews

There are no reviews yet.