In stock

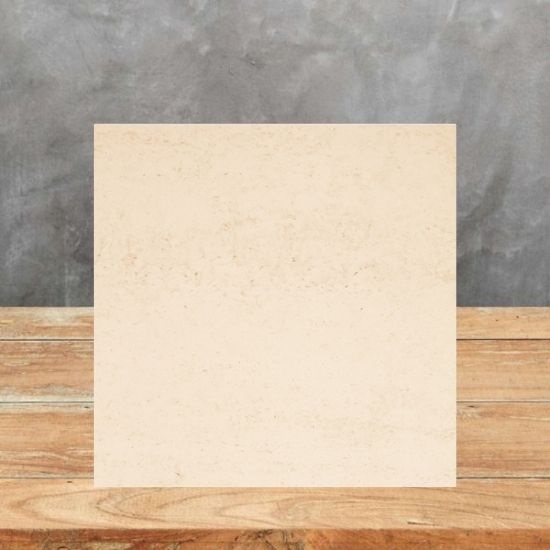

Dekton Danae

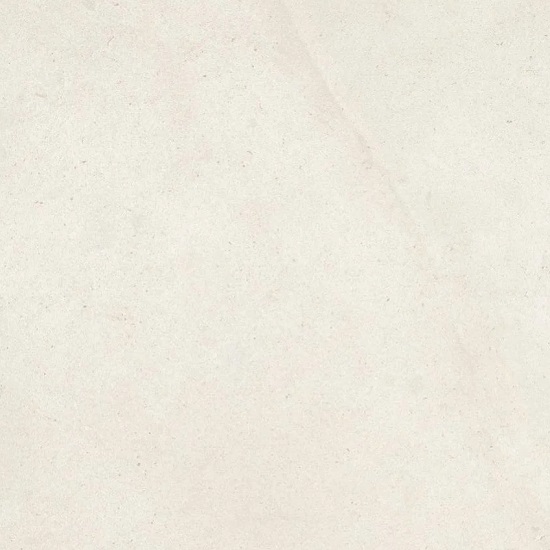

Dekton Danae mirrors several beige hues throughout this surface, capturing the idea of movement, similar to how sand flows in deserts. This gorgeous design with instant appeal offers the natural look of beige limestone and sandstone. Read More

Dekton Danae beautifully reflects various beige tones across its surface, evoking a sense of motion like the flowing sands in a desert. While resisting the allure of dark worktops, especially when paired with bright white elements, this stunning design provides an immediate attraction, showcasing the authentic appearance of beige limestone and sandstone.

Opting for Danae, especially with its captivating veining details, becomes a practical choice for families with young children.

The light-coloured stone conceals small debris on its surface, offering a significant advantage in maintaining the cleanliness inherent to this creamy-marbled stone.

Dekton Danae Highlights

- – Stunning Design: Mirrors beige hues for a natural beige limestone and sandstone look.

- – Versatile Slabs: Available in 322 x 144 cm with thickness options and a ‘Smooth Matte’ finish.

- – Ultracompact Performance: Advanced stain resistance, UV protection, water resistance, impact resistance, and heat resistance.

- – Sustainable Choice: Part of the International EPD System, achieving Carbon Neutral status.

- – Efficient Design: Large slab sizes, thickness options, and seamless finishes for an effortless installation.

- – Durable and Low Maintenance: Non-porous, scratch-resistant, stain-resistant, and tolerant to high heat.

Sustainable Design with Danae

- – International EPD System: Evaluated for greenhouse gas emissions, raw material consumption, and energy efficiency.

- – Carbon Neutral: Achieves the SDGs of Agenda 2030 for Sustainable Development.

Efficient Design and Installation

- – Slab Size: 3,200 x 1,400 mm for minimal joints, reducing installation costs and effort.

- – No Joints: Seamless slabs eliminate cutting, cleaning, and maintenance work for enhanced aesthetics.

- – Thickness Options: Choose from 0.4 cm to 3 cm for varied design preferences.

- – Finish: ‘Smooth Matte’ adds a delicate, elegant appearance to the worktop.

Exceptional Performance

- – Durability: Permanent colour without fading.

- – Large Sizes: Maximises material use with minimal joints.

- – Non-Porous: Ideal for areas in continuous contact with water.

- – Easy to Clean: Use warm water and soap for daily cleaning.

- – Stain-Resistant: Withstands various substances, including vinegar, soy sauce, ketchup, and more.

- – Scratch-Resistant: Boasts the highest rating in scratch resistance tests.

- – High-Heat Resistant: Tolerates up to 300 Celsius without cracking, burning, or scorching.

Manufacturing Process:

– Raw Material Preparation: Ensures quality and minimises cross-contamination.

– Mills and Hybridisation: A moist grinding process blends raw ingredients precisely.

– Pigmentation: Uses sophisticated technology for colour blending and quality control.

– Atomisation: Atomises and dries coloured formula for specific size, grain shape, and humidity.

– Decorating, Shaping, and Baking: Involves multiple stages to create the final slab with varied aesthetic impacts.

Transform your space with Dekton Danae, a perfect blend of beauty, performance, and sustainability.

7 Advantages for Your Home and Office with Dekton Danae Countertops

Dekton possesses all of the technical criteria necessary to change any interior or outdoor residential design concept to a highly resistant surface.

- Wide Range of Colours: there are fifty different Dekton colours across seven Collections. Dekton's Collections encompass an unlimited number of colour, finish and thickness combinations that you can use anywhere. In addition, the seven Dekton collections cover every design style and theme, namely: Natural, Tech, Solid, Industrial, Liquid, and Stonika.

- Scratch and Abrasion Resistant: the surface comprises 116 mm3 wear volume average abrasion. According to a study about the abrasion wear of natural stones, Dekton provides almost 5.5 times abrasion resistance than white marble, which offers abrasion wear of 22.23.

- Unrivalled Thermal Shock Resistance: natural stones such as marble, granite and quartzite can crack if you place a scorching item when the surface is at cool temperatures. It is because of the shock in changing temperatures between the surface's temperature and the things you are putting on it. But placing sweltering items on manufactured stones such as quartz will burn the resin on the surface, leaving unrepairable scorching. In contrast to all the stones mentioned above, high temperatures do not affect Dekton's surface. You can drag your pans and pots from the oven directly onto Dekton, which withstands up to 300 Celsius degrees of heat.

- Fireproof: Dekton is rated Class A1 (Class A1 has the highest performance and class F has the lowest), according to the UK's BS EN 13501-1 regulation, offering the highest performance regarding reaction to fire. It also means that, unlike many other stones, it can tolerate direct contact with heated cookware, devices, and cutlery without being burned.

- Easy to Clean: Dekton isn't affected by bleach in contrast to quartz. And, unlike marble, it isn't affected by acids. Instead, spray the surface with any typical household and cleaning chemical. Dekton is perfect for quick clean-ups around the kitchen and bathroom.

- Low Maintenace: it doesn't require sealants, additional coatings, primers, or enhancers. Ever. Over time, this surface's technical features save you more time and cost than any other worktop material due to its next to no-maintenance attributes.

- Stain Resistant: It can withstand any cooking ingredient, food and substance, including wine, turmeric, coffee, lemons, ketchup, etc. For the daily cleaning of DEKTON by Cosentino, use Windolene or a similar spray and a soft scouring pad. Otherwise, use water and neutral soap.

Five Additional Dekton Benefits

As a bonus, by choosing a Dekton work surface for your home and offices, you will instantly benefit from five design Extras:

- Dimensional Stability: working with the set Dekton slab sizes of 3200 x 1440 mm allows you and everyone else in your project to plan months before work on site commences, avoiding material waste and saving costs. In addition, because it expands minimally, you can fit it with narrow seams between worktops.

In all situations, the joints will maintain their minimal thickness. - High Mechanical Strength: The strength of the press used to create Dekton is up to 25,000 tonnes, equivalent to 111 Statues of Liberty, giving it the highest mechanical power in its class. Its compactness makes it available five different thicknesses, letting you use it even when your space needs protection from impact and winds.

- UV (ultraviolet) light resistance is excellent: Dekton is extremely UV resistant and does not fade or deteriorate over time in any interior or outdoor application.

- High Resistance to Hydrolysis: It is a process that controls when and to what extent the surface disintegrates. Hydrolysis is another term for the surface splitting of cheaper materials. Dekton's superior resistance is ideal for applications in bathrooms, spas, or outdoor pools and ponds.

- Resistant to Freezing and Thawing: The ability to withstand freezing and thawing: Dekton resistance's against thawing and freezing tests (UNE EN ISO 10545-12), and its use in diverse weathers demonstrate its outstanding performance.

CHEMICAL FORMULATION

Because this stone contains no resins or organic ingredients, Dekton does not employ a polymerisation process during its manufacture, and its chemical makeup is entirely inorganic.

In addition, DEKTON uses several formulas that vary according to the surface type, meaning that the final chemical structure can change without affecting its chemical or physical qualities.

Aluminium silicates, amorphous silica, crystalline silica, zircon, and inorganic colours are a few examples of DEKTON's chemical makeup. The crystalline silica component in all colours and formulations are always less than 11% by weight.

TECHNICAL CHARACTERISTICS

| TEST | STANDARD | DETERMINATION | Units | Family i | Family ii | Family iii |

|---|---|---|---|---|---|---|

| Flexural and bending strength | UNE EN ISO 10545-4 | Average flexural strength |

N |

60 | 67 | 59 |

| UNE EN ISO 10545-4 | Average bending load | N | 2.548 | 2.313 | 2.356 | |

| UNE EN ISO 10545-4 | Average bending strength | % | 14.966 | 13.559 | 13.818 | |

| Water absorption, open porosity and densities | UNE EN ISO 10545-3 |

Boiled water absorption |

% |

0 |

0,1 |

0,1 |

| UNE EN ISO 10545-3 | Vacuum water absorption | % | 0,1 | 0,1 | 0,1 | |

| UNE EN ISO 10545-3 | Open porosity | % | 0,2 | 0,2 | 0,2 | |

| UNE EN ISO 10545-3 | Apparent relative density | g/cm | 2,51 | 2,61 | 2,53 | |

| UNE EN ISO 10545-3 | Apparent density | g/cm | 2,50 | 2,61 | 2,52 | |

| Resistance to deep abrasion | UNE EN ISO 10545-6 | Abrasive volume | mm3 | 125 | 106 | 115 |

| Determination of dimensions and surface aspect | UNE EN ISO 10545-5 C | Coefficient of average restitution | - | 0.85 | 0.85 | 0.85 |

| Determination of thermal linear dilation | UNE EN ISO 10545-8 | Dilatation between 30-100ºC | ºC-1 | 6,5. 10-6 | 5,1. 10-6 | 0,3. 10-6 |

| Determination of thermal shock resistance | UNE EN ISO 10545-9 | Damage | - | Approved / undamaged | Approved / undamaged | Approved / undamaged |

| Determination of humidity dilation | UNE EN ISO 10545-10 | Maximum expansion | mm/m | 0.1 | 0.1 | 0.1 |

| Average expansion | mm/m | 0.0 | 0.0 | 0.0 | ||

| Determination of freeze resistance | UNE EN ISO 10545-12 | Damage | - | Approved / undamaged | Approved / undamaged | Approved / undamaged |

| Determination of chemical resistance | UNE EN ISO 10545-13 | ClNH4 / Cleaning products | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) |

| Bleach / Salts for pools | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| HCl (3% v/v) | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| Citric Acid (100 g/l) | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| KOH (30 g/l) | Class | UA (undamaged) | UA (undamaged) | UA (undamaged) | ||

| HCl (18%) | Class | UA (undamaged | UA (undamaged | UA (undamaged | ||

| Lactic Acid (5%) | Class | UA (undamaged | UA (undamaged | UA (undamaged | ||

| KOH (100 g/l) | Class | UA (undamaged | UA (undamaged | UA (undamaged | ||

| Determination of stain resistance | UNE EN ISO 10545-14 | Agente green | Class | 5 | 5 | 5 |

| Agente red | Class | - | - | - | ||

| Iodine (solution) | Class | 5 | 5 | 5 | ||

| Olive Oil | Class | 5 | 5 | 5 |

TECHNICAL SPECIFICATIONS

| TEST | STANDARD | DETERMINATION | UD | Family i | Family ii |

|---|---|---|---|---|---|

| Moisture expansion | ASTM C370 | Average moisture expansion | % | 0.02 | 0.005 |

| Breaking strength | ASTM C648 | Average breaking strength | Ibf | 3963 | 4896 |

| Flexural properties | ASTM C674 | Average modulus of rupture | psi | 10828 | 13997 |

| Water absorption, bulk density, apparent porosity and apparent specific gravity | ASTM C373 | Average water absorption | % | 0.03 (Impervious) | 0.05 (Impervious) |

| Static coefficient of friction (skid resistance) | ASTM C1028 | Static coef. Friction dry | - | 0.80 | 0.77 |

| Static coef. Friction wet | - | 0.66 | 0.56 | ||

| Wet dynamic coefficient of friction (DCOF) | ANSI A126.1 section 9.6.1 | Average DCOF | - | 0.57 | |

| Relative resistance to wear (Taber abrasion) | ASTM C501 | Average Abrasive Wear Index | 182.2 | 337 | |

| Thermal shock resistance | ASTM C484 | Defects | No Defects | No Defects | |

| Bond strength | ASTM C482 | Average bond strength | psi | 423 | 437 |

| Resistance to chemical substances | ASTM C650 | Common Household and cleaning chemicals | % | ||

| Acetic acid, 3% (v/v) | - | Not affected | Not affected | ||

| Acetic acid, 10% (v/v) | - | Not affected | Not affected | ||

| Ammonium chloride, 100 g/L | - | Not affected | Not affected | ||

| Citric acid solution, 30 g/L | - | Not affected | Not affected | ||

| Citric acid solution, 100 g/L | - | Not affected | Not affected | ||

| Lactic acid, 5% (v/v) | - | Not affected | Not affected | ||

| Phosphoric acid, 3% (v/v) | - | Not affected | Not affected | ||

| Phosphoric acid, 10% (v/v) | - | Not affected | Not affected | ||

| Sulfamic Acid, 30 g/L | - | Not affected | Not affected | ||

| Sulfamic Acid, 100 g/L | - | Not affected | Not affected | ||

| Swimming pool chemicals | - | Not affected | Not affected | ||

| Sodium hypochlorite solution, 20 mg/L | - | Not affected | Not affected | ||

| Acids and bases | |||||

| Hydrochloric acid solution, 3% (v/v) | - | Not affected | Not affected | ||

| Hydrochloric acid solution, 18% (v/v) | - | Not affected | Not affected | ||

| Potassium hydroxide, 30 g/L | - | Not affected | Not affected | ||

| Potassium hydroxide, 100 g/L | - | Not affected | Not affected | ||

| Absorption and bulk gravity | ASTM C97 | Average weight per cent absorption | % | 0,02 | 0,04 |

| Average density | Ib/f | 156 | 160,63 | ||

| Modulus of rupture | ASTM C99 | Average modulus of rupture dry conditions | psi | 8128 | 9042 |

| Average modulus of rupture wet conditions | psi | 7490 | 8446 | ||

| Flexural strength | ASTM C880 | Average flexural strength dry conditions | psi | 6840 | 3118 |

| Average flexural strength wet conditions | psi | 6205 | 4187 | ||

| Compressive strength | ASTM C170 | Average compressive strength dry conditions | psi | 34409 | >55000 |

| Average compressive strength wet conditions | psi | 17823 | >55000 | ||

| Abrasion resistance | ASTM C1353 | AverageAbrasion Index | - | 349 | 349,48 |

SLIP RESISTANCE REPORT

According to STANDARD EN -14.631Family I (Spectra, Domoos, Sirius, Sirocco, Kadum, Strato, Keranium, Ananké)

| Finish | NATURAL | NATURAL | SLATE | SLATE | WOOD | WOOD | POLISHED | POLISHED |

| Colour | PDomoos / Strato / Sirocco / Kadum / Keranium | PDomoos / Strato / Sirocco / Kadum / Keranium | Sirius | Sirius | Ananké | Ananké | Spectra | Spectra |

| Determination | PSRV dry | PSRV wet | PSRV dry | PSRV wet | PSRV dry | PSRV wet | PSRV dry | PSRV wet |

| Value | 48 | 23 | 49 | 22 | 44 | 21 | Pending Test | Pending Test |

COLOUR AND TONES

Cosentino assigns numbers to describe tones in the colours (slight changes in coloUr intensity), and each slab is defined by Colour & Tone.

Here are the factors that determine Dekton colours and tone variation:

- Colours in solids: E variant (control with) The slab unit label with Colour and Tone Code reflects the colour and tone.

- The label determines the slab's Tracing and its history. As it progresses through the industrial manufacturing operation via the slab number (batch).

- Spectrophotometer settings: Lab/D65/10o).

- Colours with veins: visible differences (of pattern)

Dekton: 25-year warranty

Besides technical superiority, originality, and style, Dekton offers a 25-year warranty on its designs.

You need to provide your invoice/receipt when filling out the Dekton warranty form within 6 (six) months of your purchase to activate your warranty.

If you don't activate your warranty within this period, you will enjoy the same benefits for 2 (two) years.

RETURNS AND SHIPPING POLICY RETURNS

Except for damaged surfaces, all sales are final. Please call 020 39760029 or email [email protected] for more information before mailing exchanges or online purchasing return products installed in faulty or damaged condition.

SHIPPING \ TURNAROUND

We process all orders within one business day. However, please remember that specific stones may have longer lead times due to high demand or special-order items from other countries.

DELIVERY & INSTALLATION COSTS

We compute delivery and installation costs at the time of purchase. Our team of professional stone fitters install all stone surfaces.

Installation and delivery charges vary depending on weight, site access, and delivery location from our workshop in West London, United Kingdom.

INSTALLATION & DELIVERY ADDRESSES

Stone worktop installation is available in London and 150 miles surrounding areas. Please contact our Worktop Library Service Team at (20) 39760029.

Reviews

There are no reviews yet.