© 2022 All rights reserved Worktop Library

If you’re wondering how Silestone quartz is made, consider this. Quartz Surface manufacturing starts in a quarry and continues in a production line. It undergoes several industrial and logistical processes to ensure that the best quartz crystals are selected. This is what makes the best quartz slabs. Quartz manufacturing never stops! Let’s see how the manufacturing process of Silestone works, step by step.

What you will learn on this article

- Where the most prominent quartz quarries in the world are located

- The quartz production plant: Silestone’s manufacturing facilities

- Storage and distribution of the quartz slab’s ingredients

- Consistency of the material: baking a silestone slab

- Final quality control phase

- Packaging and storage of the finished slab

- Silestone features and benefits

- Silestone edges

- Formats from silestone

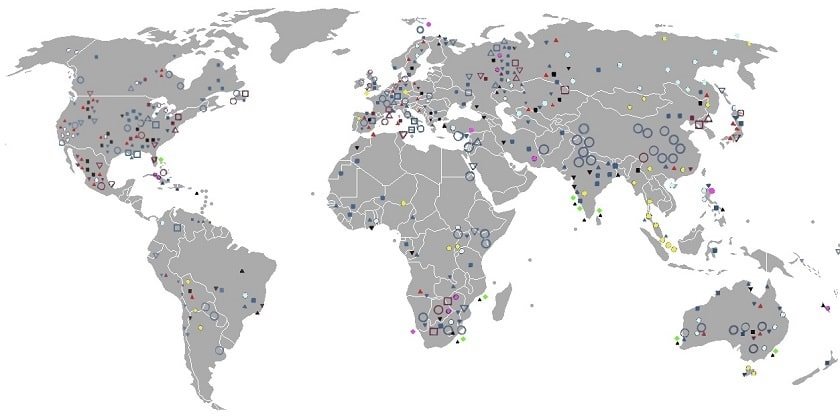

The most prominent quartz quarries in the world

Quartz is the most abundant mineral on earth. Its sustainability and strength make it a preferred kitchen worktop material among architects and interior designers everywhere. Similarly, just like a marble surface, a quartz quarry must be maintained yearly. We do so by keeping checks on the stone’s quality that we extract. And although we quarry quartz in many places around the world, the locations of the popular quartz are in the USA (In fact, the most prominent quartz quarry in the world is in Mount Airy and nicknamed ‘Granite City’ (ref.1) Brazil and Australia.

The quartz production plant: the manufacturing facilities at silestone

Here, we receive the raw materials and carry out the first quality control phase. At the production plant, everything begins with the reception of the raw materials. At Cosentino, which makes Silestone the largest quartz slab manufacturer globally, they receive over forty truckloads of raw materials daily. Some of these materials are quartz crystals, aggregates, and additives. And it involves a thorough organization of the logistics at the industrial sites. Before storing the raw material, the laboratory team uses the most advanced technologies for the first quality control check. Therefore, this process ensures that the raw materials fulfil all the quality control standards regarding mechanical resistance, purity and granulometry. Indeed, this step of the process is crucial is fundamental for obtaining a top-quality final product.

Storage and distribution of the main ingredients

With the approval of the Laboratory, we store the materials received by tanker trucks in silos. We store these with an airtight system, free from impurities. Firstly, we load the aggregates acquired in sacks into hoppers after travelling along with conveyor belts, allowing for optimization of the material. Secondly, we store the resin in special stainless-steel terms. The material is now ready to be transformed into Silestone. Thirdly, In the control panel, we introduce the Silestone Colours Formula, which we will manufacture. And automatically, the extraction of the materials from the silos commences.

Later, we transport the aggregates, resins, and the exclusive anti-bacterial protection into the mixers, where we homogenize all the materials to form a mass. Using a system of conveyors belts, we transport the mix into the press, passing a distributor which shapes the slab. The slab also undergoes continuous weight control with the aims of obtaining the perfect distribution of the mixture.

Consistency of the material: baking a silestone slab

We now reach the press, which is ultimately responsible for giving the product the consistency with which we are familiar. At this time, via sophisticated vacuum cleaning and simultaneous vibrations systems, we extract all the air from inside the mass, obtaining the desired compactness. We are now on the point of getting Silestone. The only thing now remaining is to bake and polish the mix.

Our unfinished slab will now spend thirty minutes in the oven at 100C and cool naturally for 24hs. Once we finish with the cooling process, the slab undergoes a pressing phase with the desired shape. And a calibration process is necessary for the slabs to obtain the standard thicknesses and finish that the customer requires utilizing a polishing stage. Using a discs and drilling mills system, we eliminate the excess material created during the pressing phase. Next, we stamp the Silestone logo on the underside of the slab. Now, the slab has its standard measurement. And without leaving the line, various polishing machines give the slab the final finish, which is so characteristic of Silestone.

Interested in Silestone worktops? Get a Free Quote.

Final quality control phase

Finally, the quality control phase ensures the perfect condition of the product through a thorough inspection of the slab, verifying the customer’s specification regarding shine, tone, aspect, and size. Subsequently, we take the polished slab into the warehouse facility for sale or into a production factory. Then, we make the material into a made-to-measure product for you, the customer. In this factory, the slab passes a second quality control check. And once we mark out its usable surface area, we register the slab into a database. We then place the slab into an intelligent warehouse with a capacity for many thousands of slabs. Also, three independent production plants are covering the present demand for orders.

Packaging and storage of the finished product

After passing the quality and shipping controls, we proceed to package the finished product. To conclude, the factory always works with the regulations governing risks preventions using health protections and monitoring systems. Of course, to which the brand is committed.

Features and benefits

After making the slab, the product is ready to fabricate into a kitchen worktop surface. Of course, Silestone offers a number of benefits when compared to other worktop materials like marble or granite:

- Availability: because Silestone making takes place in a manufacturing facility, it’s produced in mass quantities, ensuring enough product is available to satisfy the market. In comparison, natural stones’ availability depends on several factors such as mining capabilities and transportation.

- Wide range of options: similarly, Silestone offers a wide range of colours, stunning textures and outstanding properties, which the brand makes according to the client’s specifications.

- Thicknesses: you can choose Silestone from thicknesses of 12mm, 20mm, and 30mm. It gives you ample possibilities for applications such as kitchen worktops, vanity tops, wall and furniture cladding.

- Finishes: you can choose Silestone Polished, which offers unparalleled shine. In contrast, if you prefer a matt finish, you can go for Silestone Suede Finish. Additionally, if you are looking for a rough texture, you can opt for Silestone Volcano Finish.

- Warranty: Cosentino offers its customers a 25-year warranty on Silestone kitchen worktops. In contrast, marble are granite doesn’t come with manufacturer’s warranties. But there are exceptions from branded natural stones such as Sensa Granite and Naturamia.

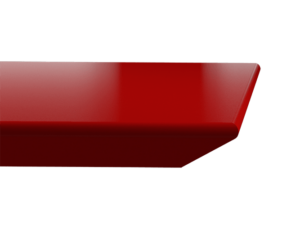

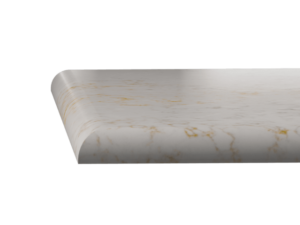

Silestone edges

The most popular Silestone edges are the Pencil edge and the Bevel edge profiles. But you can choose from many types of edges, available in all Silestone colours. In short, here are some types of edges you can choose from:

Formats from silestone

The company makes different formats for its kitchen surface products so you can optimize your space as best as possible:

- Silestone slabs: the brand gives you the choice of two slabs sizes: the standard sheet of 306 x 140 cm and the Jumbo slab of 325 х 159 cm, both available for minimal joints in any kitchen.

- Silestone tiles: because each home is different, Silestone offers different floor tile sizes for projects of any scale: 30x30cm, 40x40cm, 60x30cm, 60x40cm or 60x60cm.

You can learn about Silestone’s prices by clicking here.

Additionally, if you are interested in knowing more about how Silestone is made, watch this video:

Here, is where the process of creating Silestone finishes. We hope you have enjoyed this article. Goodbye!

Author:

Alan Nussbaum

Meet Alan Nussbaum, our Sales and Marketing Manager. With almost two decades of experience, Alan’s impressive track record includes creating one of the first online stone companies in 2012 and pioneering the acceptance of cryptocurrencies in construction in 2018 before co-founding The Worktop Library with Maria.

Alan’s work is featured in numerous Stone and Home Decor magazines. In addition, he collaborates with the industry’s leading stone brands, cementing his reputation as an innovator.

Before starting a thriving career in the stone industry, Alan honed his skills by overseeing luxury fashion brands such as Burberry, Matches Fashion, and Patrick Cox. With his unique blend of experience and expertise, Alan is a true trailblazer in the stone worktop industry. His passion for delivering exceptional service is evident in every aspect of his work.

Apr 16 2021

Apr 16 2021  Apr 19 2021

Apr 19 2021  May 05 2021

May 05 2021  May 07 2021

May 07 2021  May 15 2021

May 15 2021  May 17 2021

May 17 2021