© 2022 All rights reserved Worktop Library

I know what you feel when you plan your dream kitchen. I’ve been there myself, and every detail counts. You have a vision of modern, durable, and gorgeous worktops that don’t only look good but also last for a very long time, given the scale of your investment.

Let me present you with porcelain, a material that is traditionally associated with tiles but is now making waves as porcelain slabs for worktops — also known as sintered stones.

But what exactly is the difference between these porcelain types, and why should you consider one over the other for your kitchen worktops?

We All Know Traditional Porcelain Tiles

First, let’s break down the traditional porcelain tiles. These contain clay, feldspar, and quartz, and we see them everywhere, from interiors to exteriors, for their strength, low water absorption, and resilience.

Conventional porcelain tiles have been a staple in homes for decades, providing a combination of beauty and durability that homeowners have come to rely on. But, as worktop materials, they might not always hit the mark.

“Traditional porcelain tiles are fantastic for using smaller panels in flooring and walls but might not offer the large seamless surfaces, photo-realistic look and strength required for modern worktops,” says

Me, Alan at The Worktop Library. 🙂

Porcelain worktops, aka Sintered Stone

What Are Sintered Porcelain Slabs?

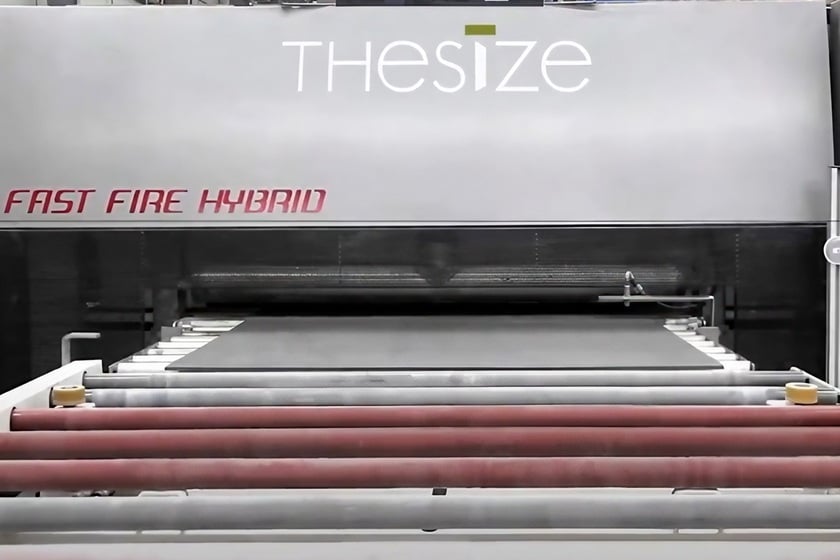

On the other hand, porcelain slabs, or sintered stones, are designed precisely for those hardworking surfaces. These slabs undergo a unique process called direct sintering, which alters their structure to provide superior performance compared to their tile counterparts.

This process involves heating the material at very high temperatures, resulting in a finished product renowned for its high compaction, mechanical strength and resistance to heat, scratches and stains.

- 1. Strength and Durability: Porcelain slabs are known for their high mechanical strength, making them ideal for kitchen worktops that face daily wear and tear.

- 2. Seamless Design: With large slab sizes, sintered stones offer a premium finish that traditional tiles cannot compete with

- 3. Low Water Absorption: Perfect for the kitchen or bathroom space, porcelain slabs repel water, reducing the risk of stains

- 4. Eco-Friendliness: Direct sintering technology reduces energy consumption during production, making these porcelain worktops a greener choice.

Sintered Porcelain Production Simplified

Sintered Stone Manufacturing

Porcelain, the durable and translucent ceramic you’ve known for years, relies on a blend of clay, feldspar, and quartz. These materials work in balance, each playing a vital role. Clay gives the mixture its pliability, feldspar encourages glass formation, and quartz remains undissolved to contribute strength.

- The Role of Sintering: Then, the magical transformation that happens with heat. Traditionally, porcelain production involves a significant energy consumption mainly during the firing process. That’s where sintering does its thing, altering properties to achieve that sought-after durability without aesthetic compromise.

- Enter Direct Sintering: Imagine cutting down your energy bills by half. Direct sintering not only slashes the waiting time by about 50% but also reduces the required sintering temperature from the usual 1200 °C to 1175 °C. This is much more efficient than conventional porcelain processing.

- Heating Rates Explained: According to a study carried out by the Centre for Advanced Structural Ceramics at The Imperial College of London, When comparing different heating rates — 5, 15, and 30 °C/min — and concluded that direct sintering matched the physical and mechanical properties of traditional methods. Interestingly, while mullite formation remains steady across various heating rates, glass formation does not.

Now that you know what makes sintered porcelain different from your traditional porcelain tile, you will have some questions to ask. Here are some of the queries our customers at The Worktop Library often ask us about porcelain, ceramic worktops and sintered stone materials:

Are all porcelain worktop brands the same?

Not exactly. Each manufacturer tweaks the formula above by using remnants from marble, granite, minerals, glass, sand and other raw materials, giving each porcelain brand their unique flavour and finishes.

Are porcelain and ceramic worktops the same?

Porcelain and ceramic worktops share similarities, being both clay-based materials. But they differ hugely in composition, aesthetics, and cost. Porcelain tends to last longer and has more aesthetically versatile options, while ceramic is a little more economical holding similar appeal.

| BRAND | SINTERED STONE TYPE | MANUFACTURER’S WARRANTY |

| Neolith by The Size | Ceramic | 25 years |

| Marazzi The Top Worktops | Porcelain | 25 years |

| SapienStone | Porcelain | 10 years |

| Dekton by Cosentino | Porcelain | 25 years |

| Laminam | Ceramic | 25 years |

| Infinity Surfaces | Porcelain | 10 years |

| Xtone by Porcelanosa | Porcelain | 25 years |

| Ascale by Tau | Ceramic | 15 years |

| Techlam Top by Levantina | Ceramic | 25 years |

| Arklam Supersize | Ceramic | 20 years |

| Atlas Plan | Porcelain | 10 years |

| Caesarstone | Porcelain | 25 years |

| Ceralsio by CRL Stone | Ceramic | 10 years |

| Uniceramica by Brachot | Ceramic | 10 years |

| ABK Stone | Porcelain | 25 years |

| Inalco | Ceramic & Porcelain | 5 years |

Can porcelain slabs be used in both kitchen and bathroom settings?

Yes. Porcelain slabs made from sintered stone are a top choice for kitchens and bathrooms due to their non-porosity, avoiding the intrusion of liquids onto their surface, thus helping prevent the growth of mould and bacteria.

In kitchens used for countertops, backsplashes, and floors thanks to their heat, scratch, and stain resistance. Bathrooms benefit from their water-resistant qualities, making them perfect for shower trays, wall cladding, and flooring.

Easy to maintain, they offer long-lasting beauty for busy kitchen and bathroom spaces.

What does the future for porcelain worktops?

Direct sintering has a bright future, possibly replacing conventional practices. By optimising speeds and energy consumption, this reasonably new technique to create work surfaces continues pushing the boundaries of ceramic production into a new era of efficiency and eco-friendliness.

Check Out Our YouTube Video Summary

Do you want to see sintered porcelain slabs in action? Our YouTube video takes you on a visual journey, showcasing the stunning versatility and durability these worktops bring to modern kitchens. Discover how these slabs are only just stone but transformative elements in home design!

Conclusion

Understanding the nuances between traditional porcelain tiles and sintered porcelain slabs, often known as sintered stones, empowers you to make informed choices for your kitchen worktop. The new direct sintering process, highlighted in this research, brings a more energy-efficient and environmentally friendly way of manufacturing while retaining the durability and aesthetic appeal of conventionally-fired porcelain. Ready to elevate your kitchen with a modern porcelain worktop? Explore your options today and make a sustainable choice for your home.

Author:

Alan Nussbaum

Meet Alan Nussbaum, our Sales and Marketing Manager. With almost two decades of experience, Alan’s impressive track record includes creating one of the first online stone companies in 2012 and pioneering the acceptance of cryptocurrencies in construction in 2018 before co-founding The Worktop Library with Maria.

Alan’s work is featured in numerous Stone and Home Decor magazines. In addition, he collaborates with the industry’s leading stone brands, cementing his reputation as an innovator.

Before starting a thriving career in the stone industry, Alan honed his skills by overseeing luxury fashion brands such as Burberry, Matches Fashion, and Patrick Cox. With his unique blend of experience and expertise, Alan is a true trailblazer in the stone worktop industry. His passion for delivering exceptional service is evident in every aspect of his work.

Apr 16 2021

Apr 16 2021  Apr 19 2021

Apr 19 2021  May 05 2021

May 05 2021  May 07 2021

May 07 2021  May 15 2021

May 15 2021  May 17 2021

May 17 2021