In stock

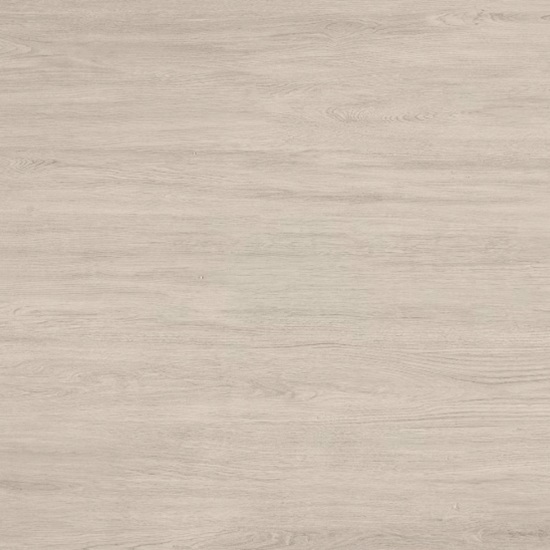

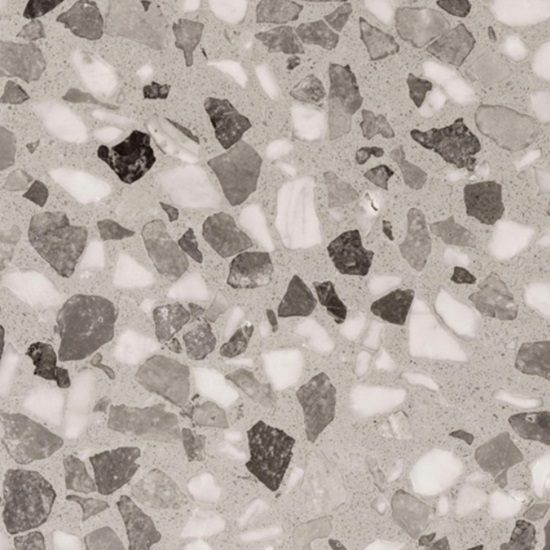

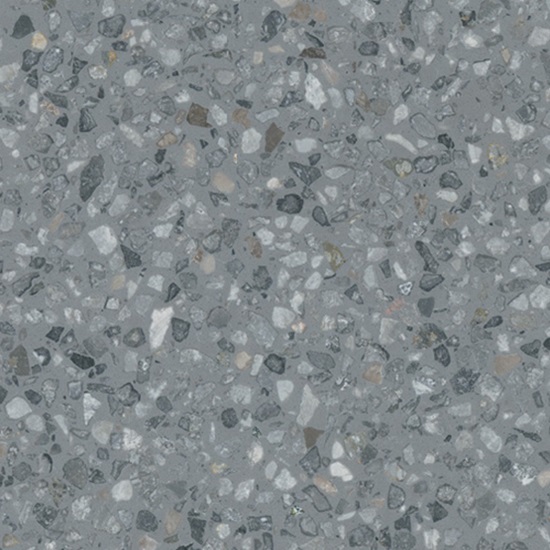

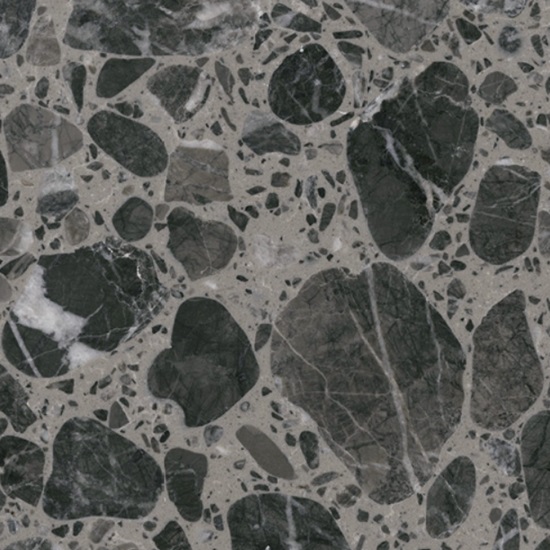

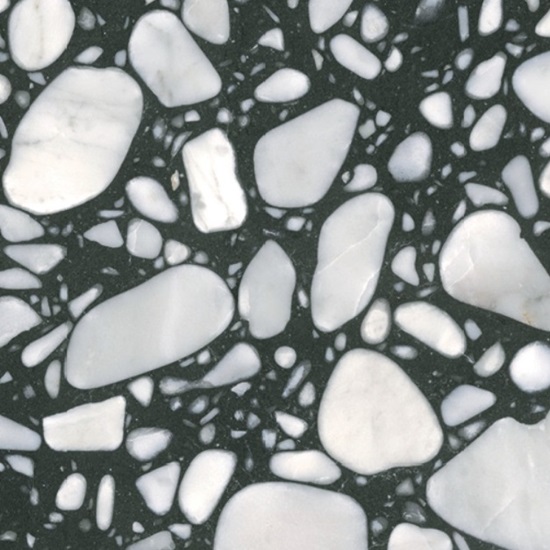

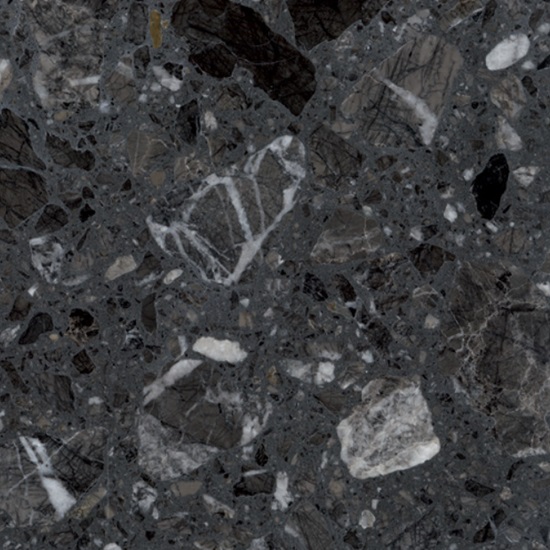

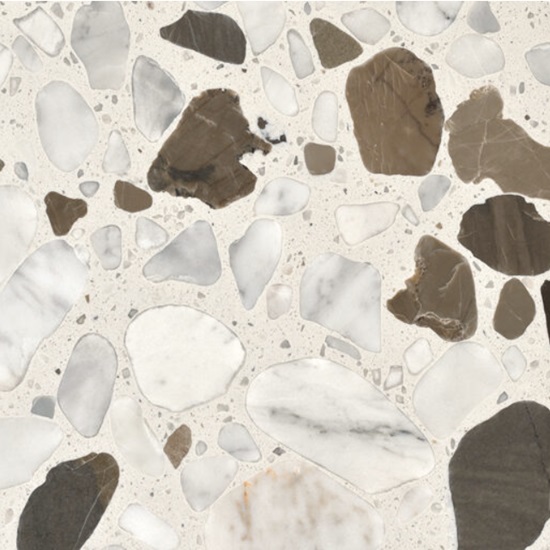

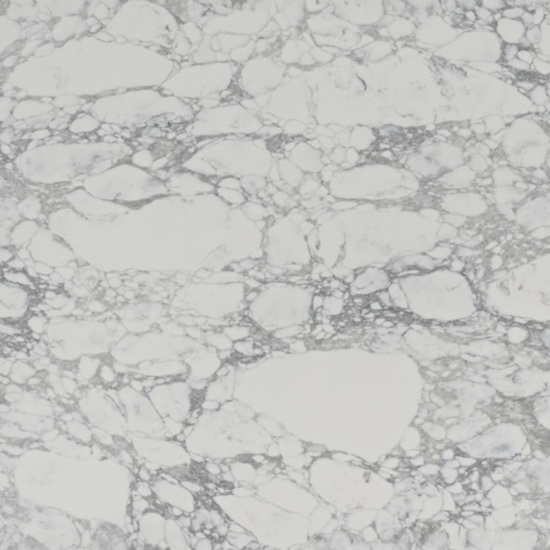

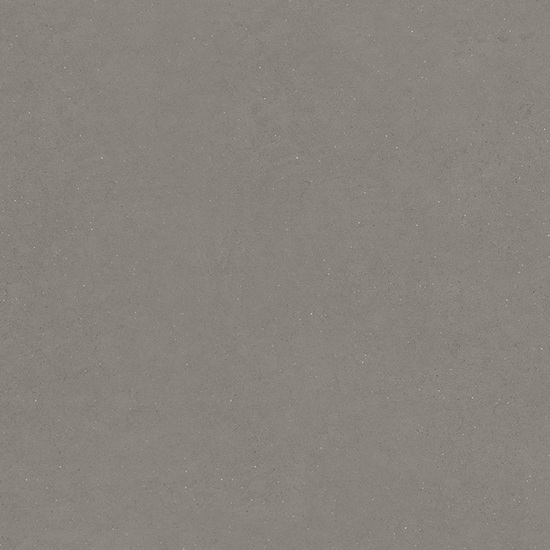

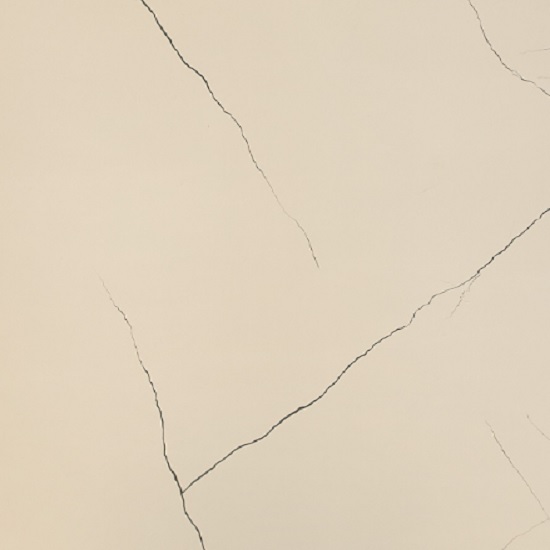

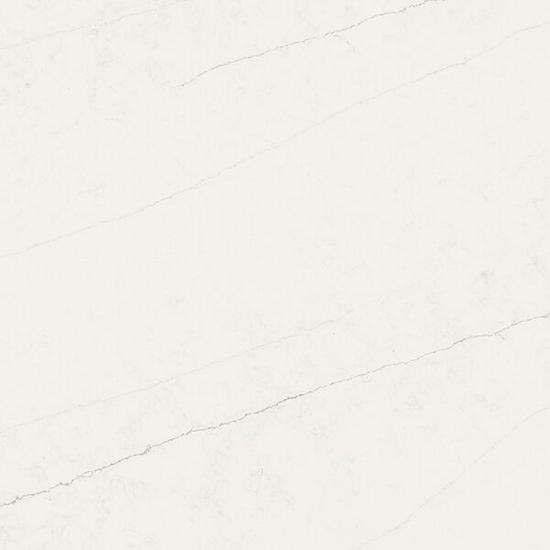

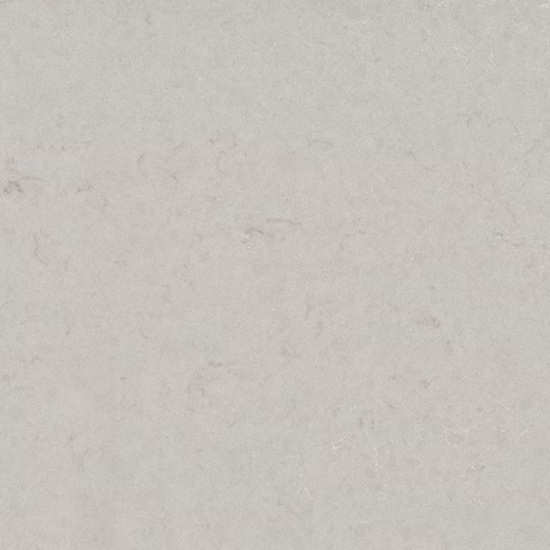

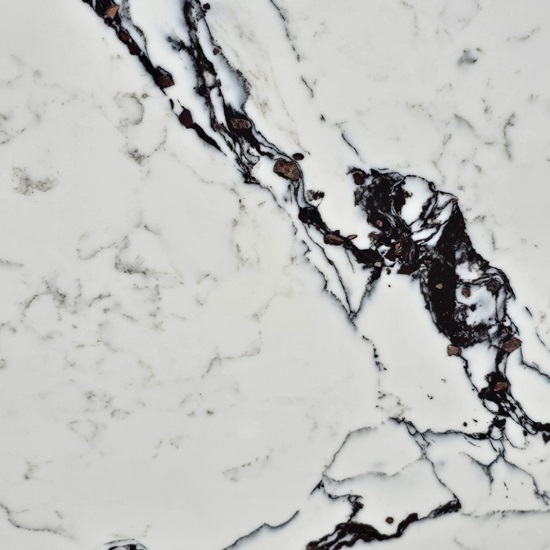

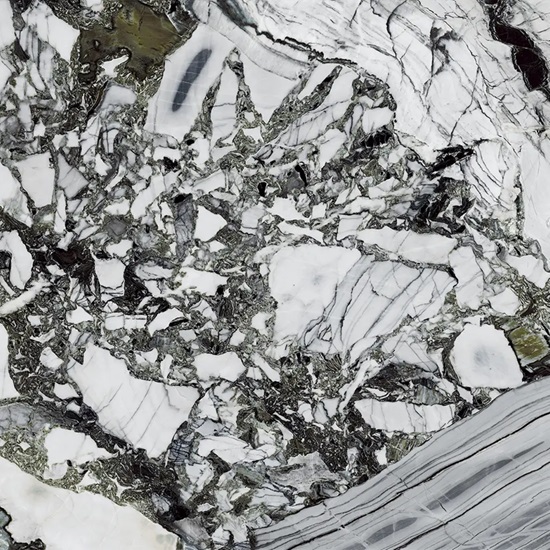

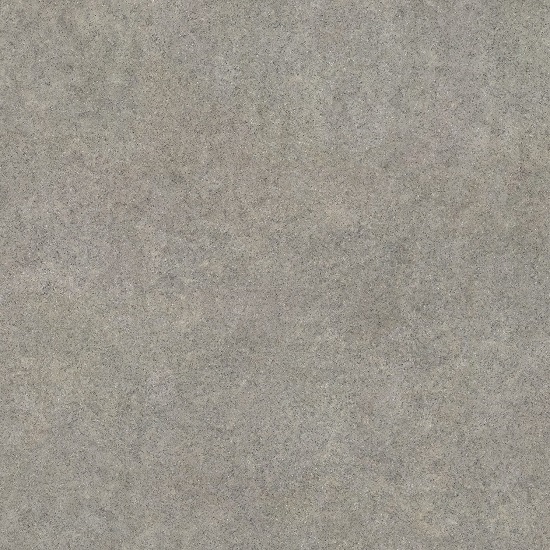

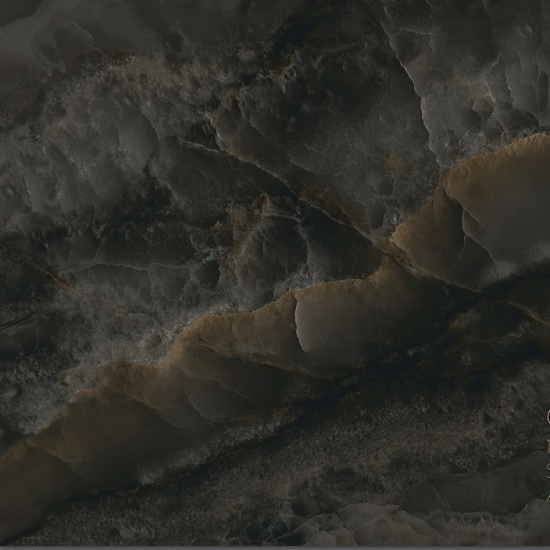

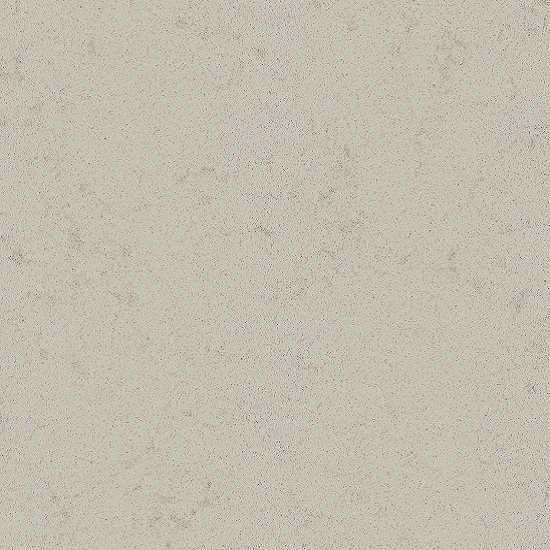

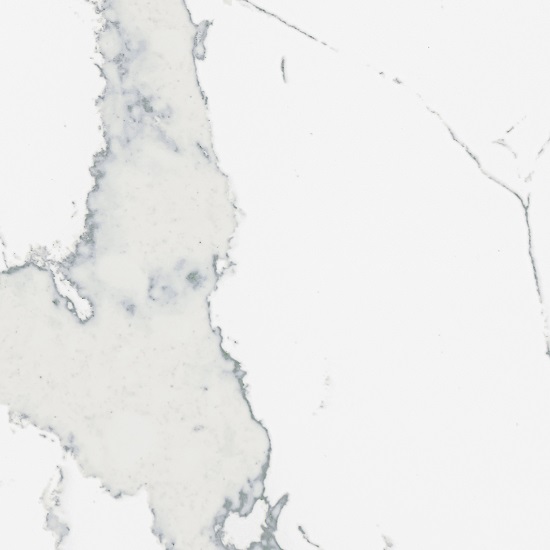

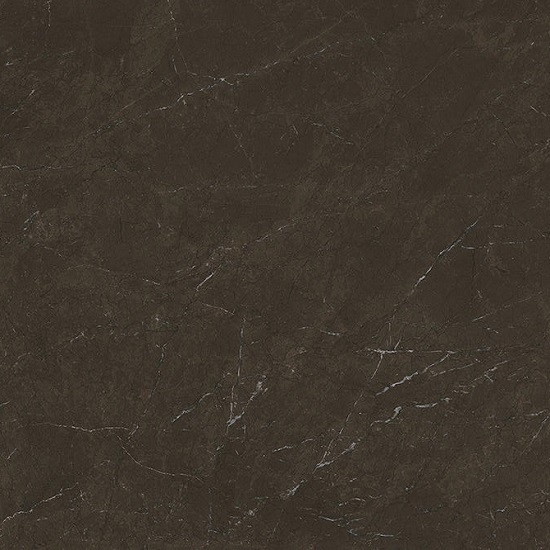

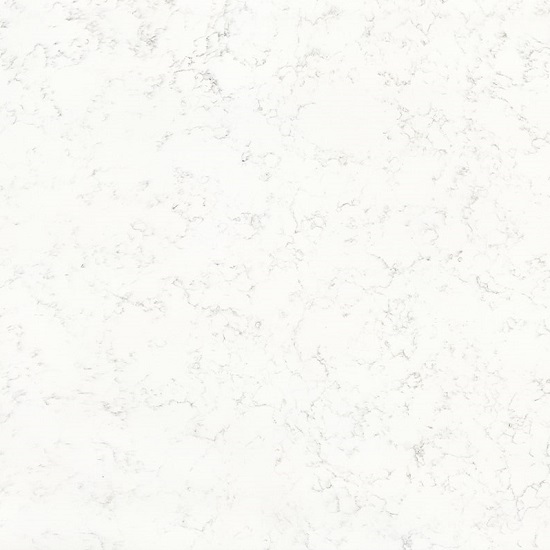

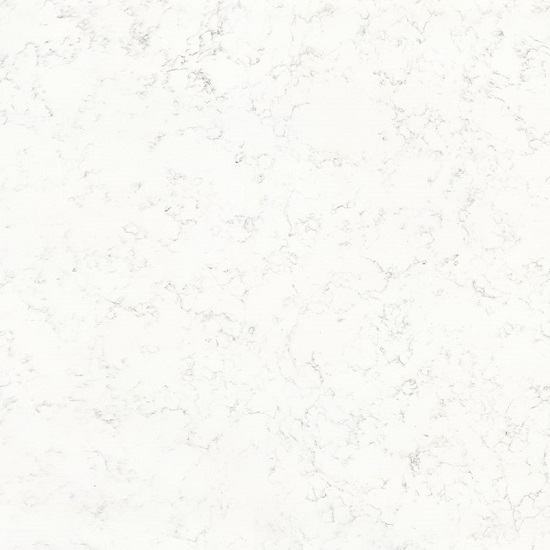

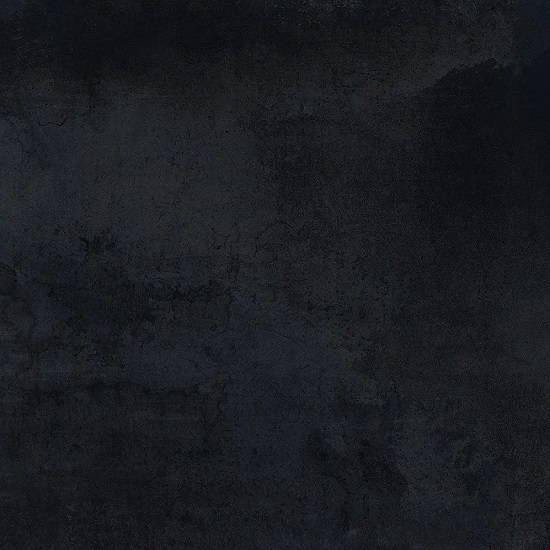

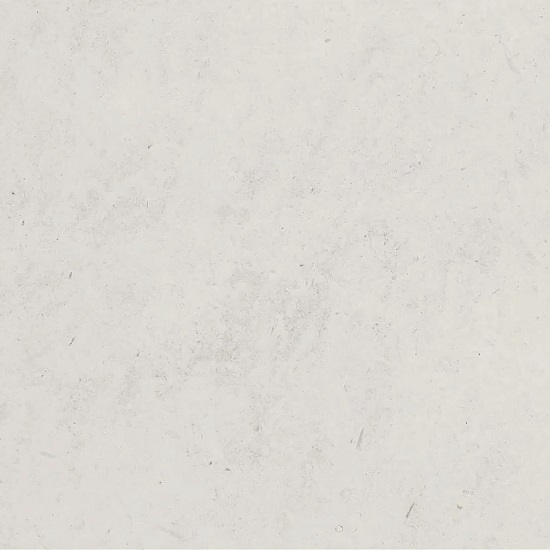

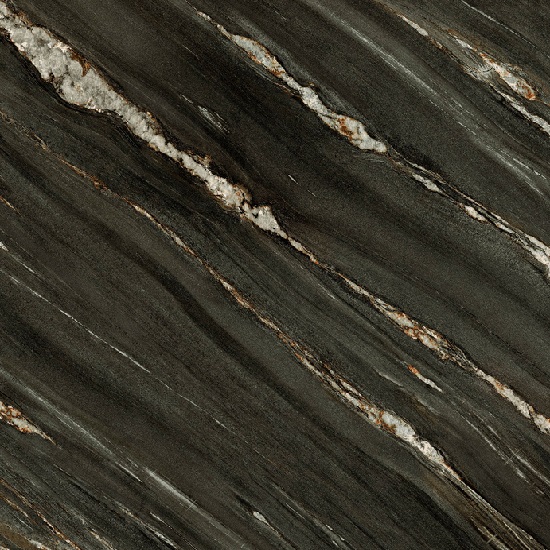

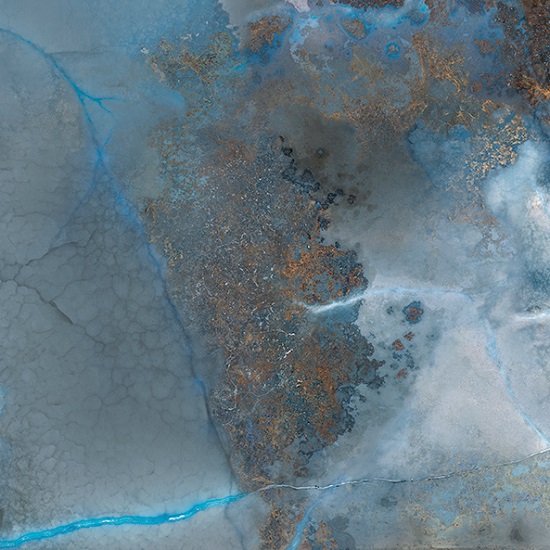

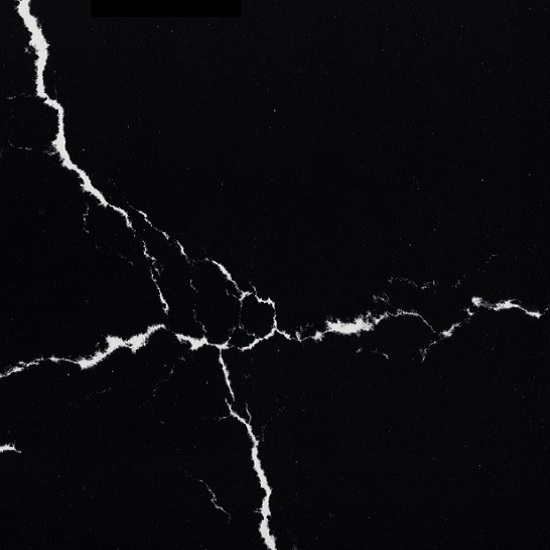

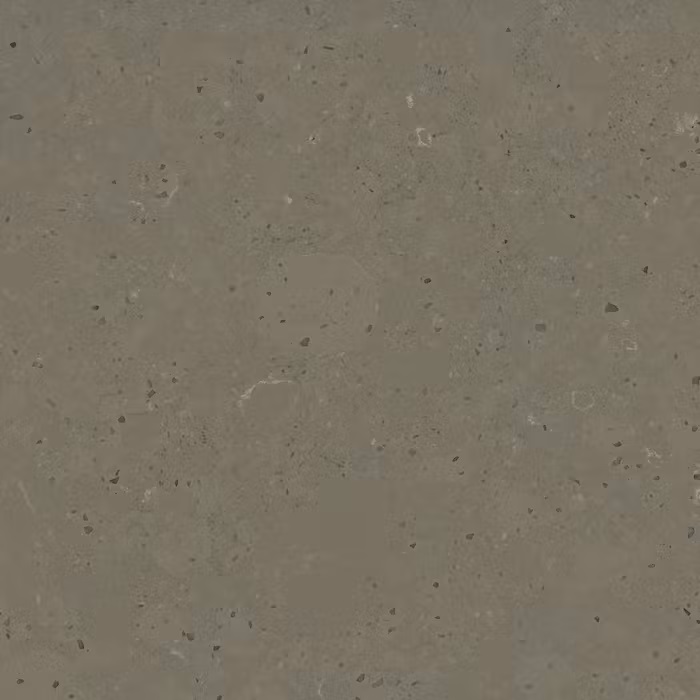

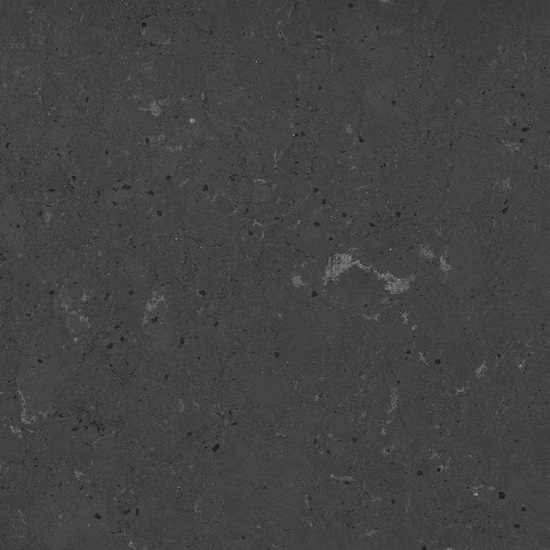

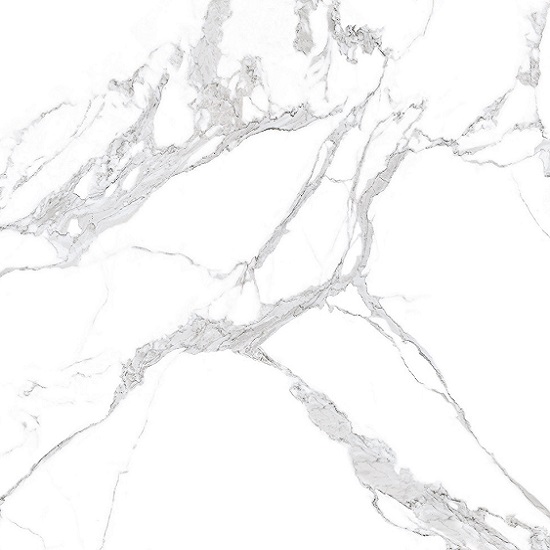

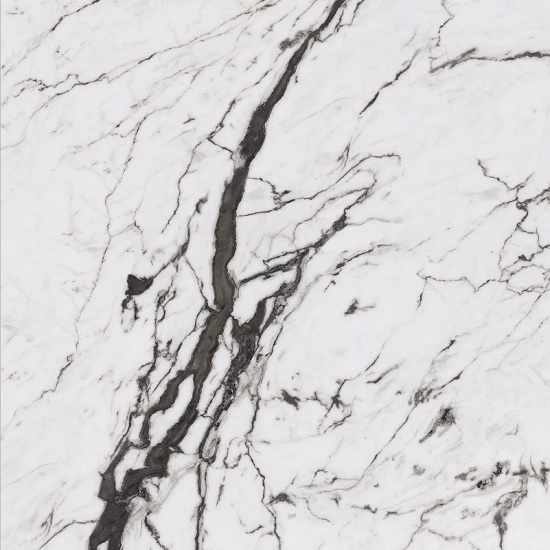

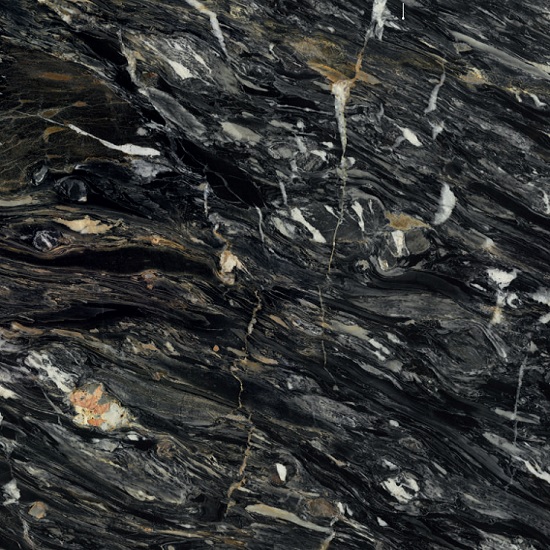

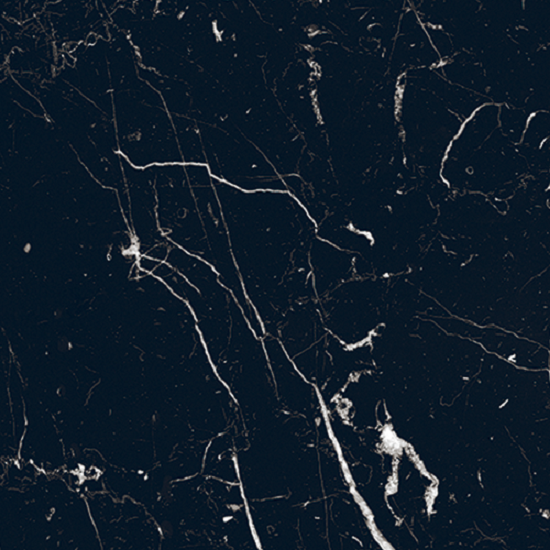

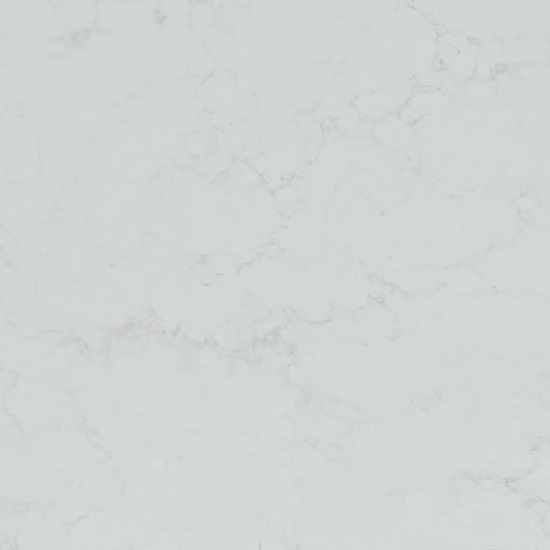

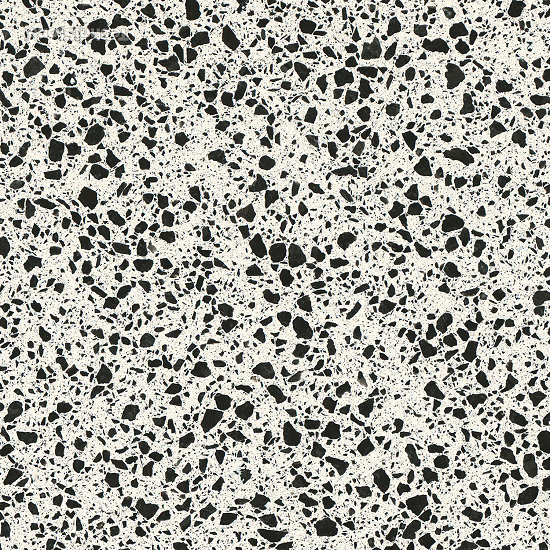

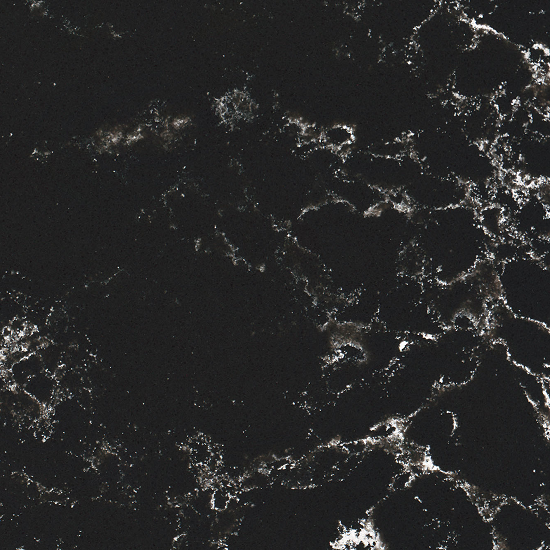

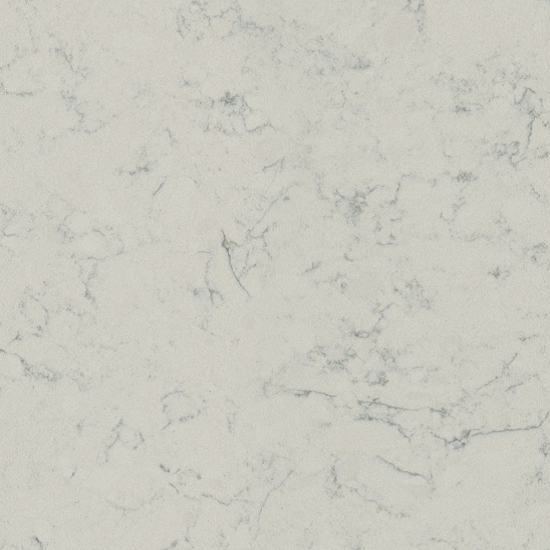

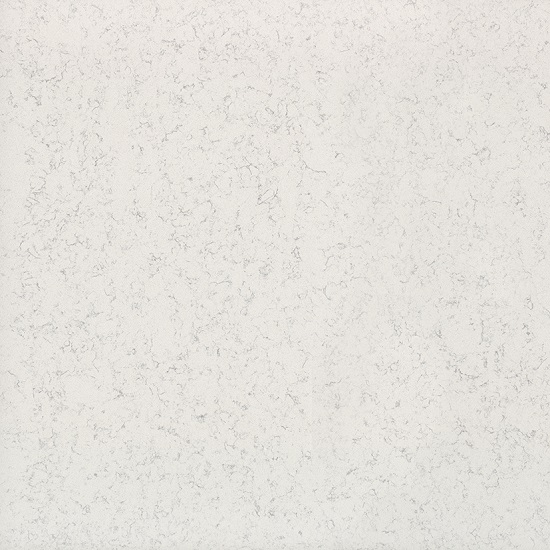

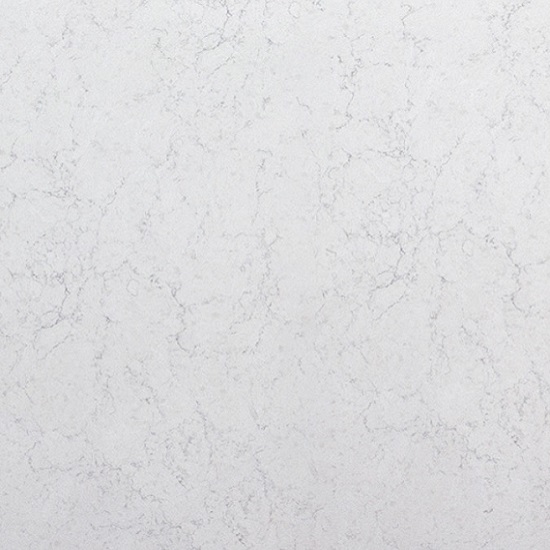

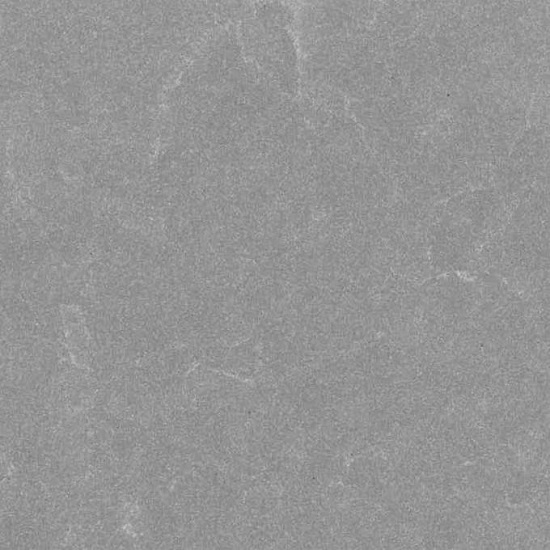

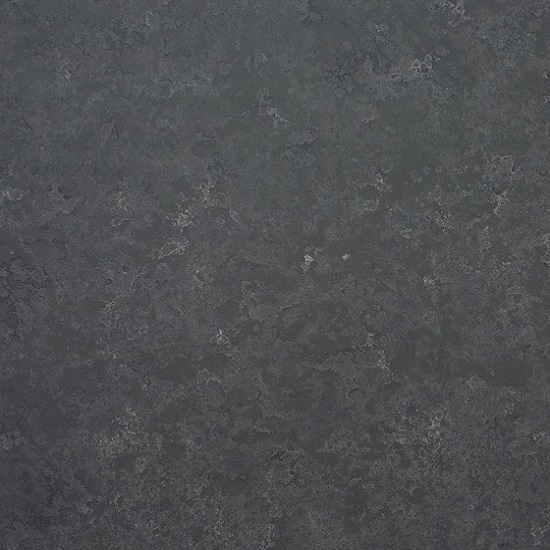

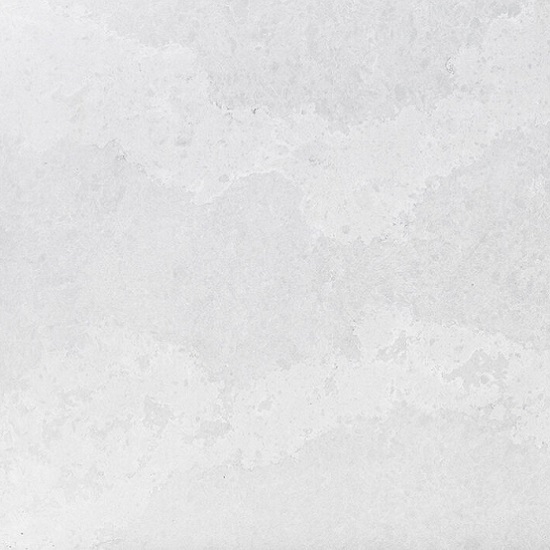

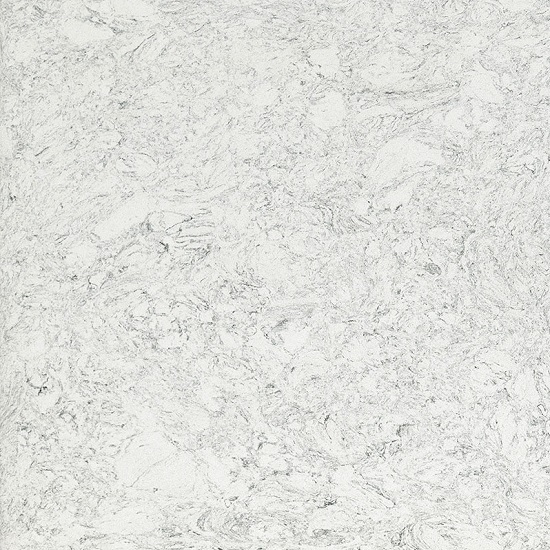

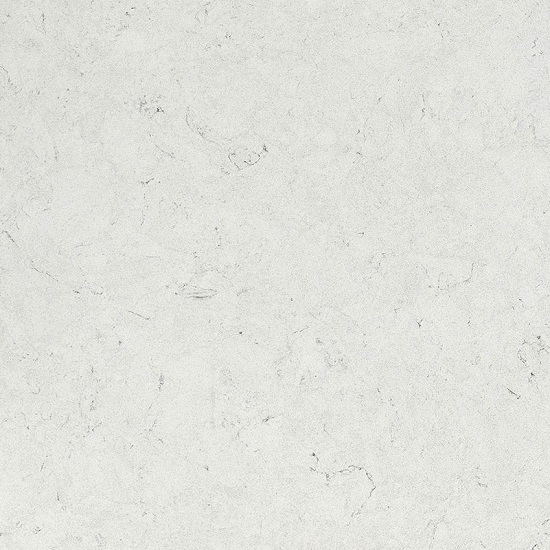

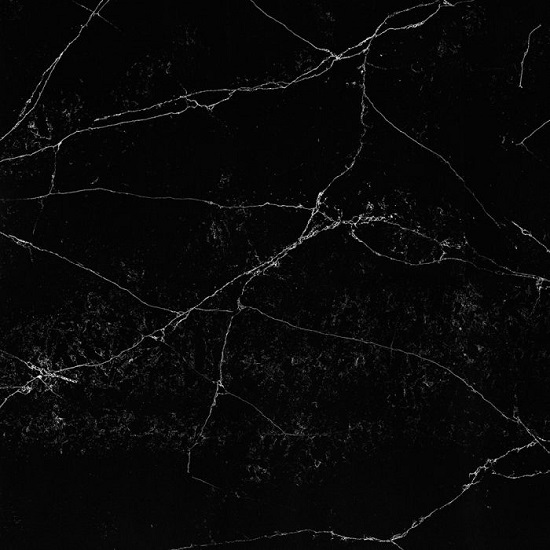

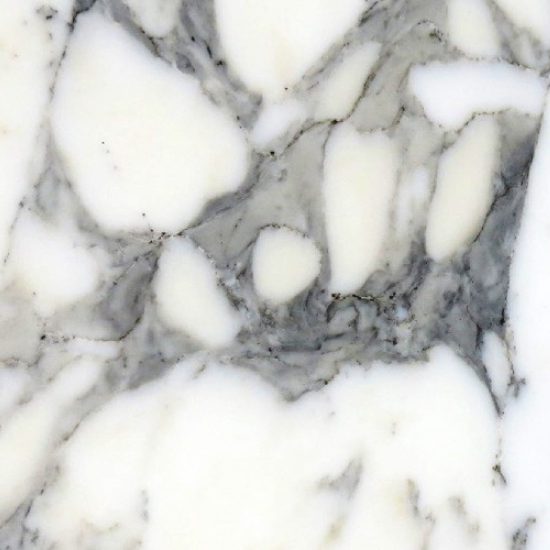

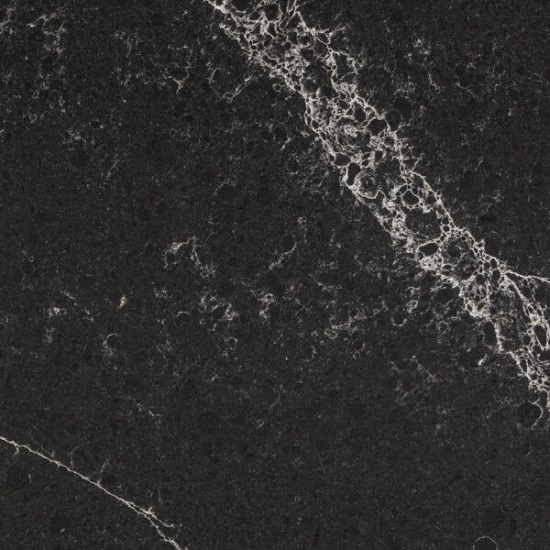

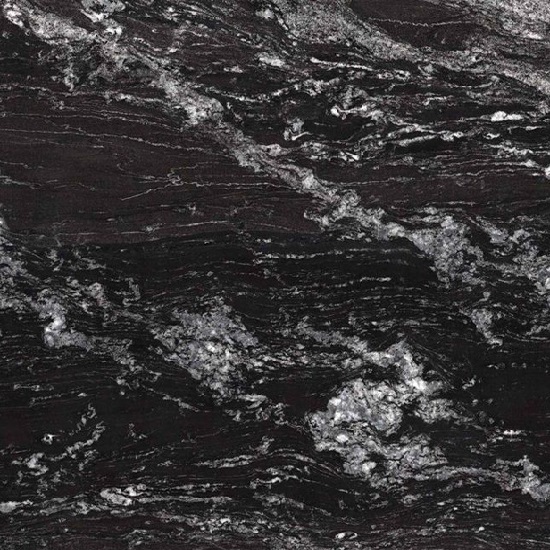

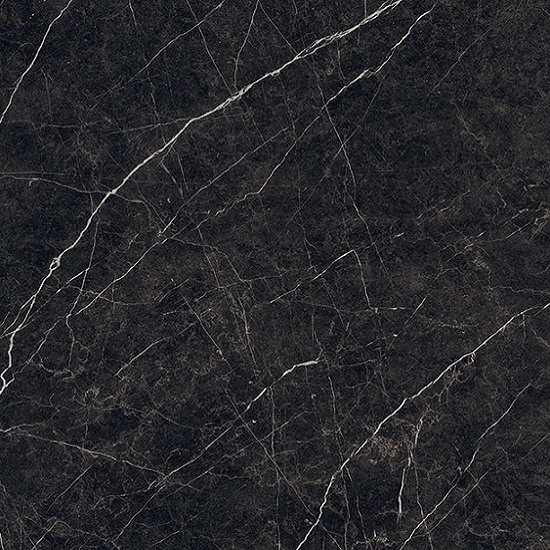

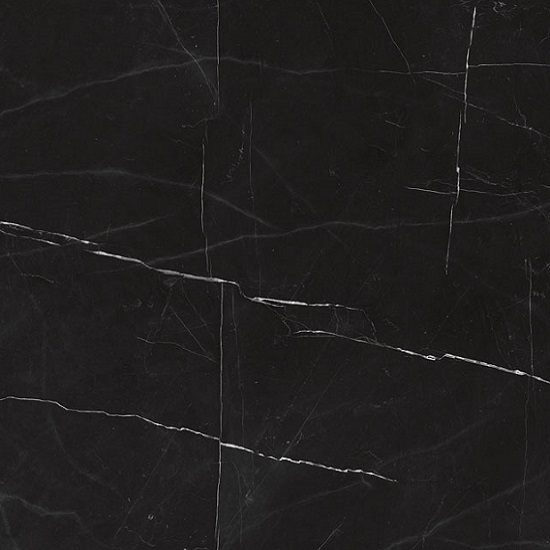

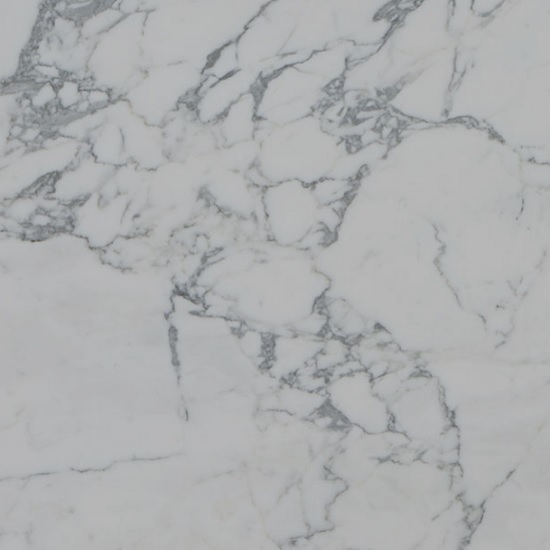

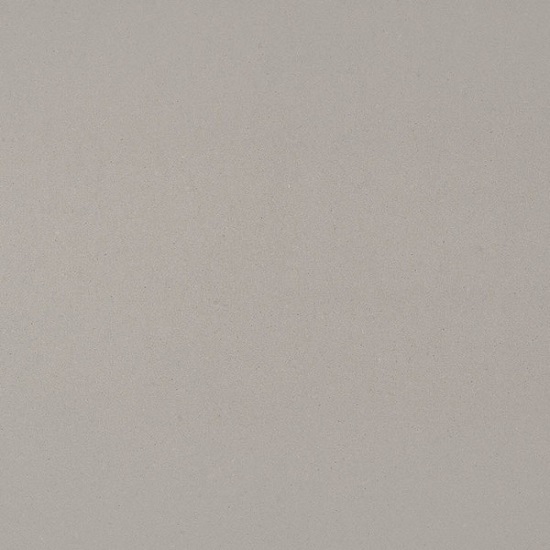

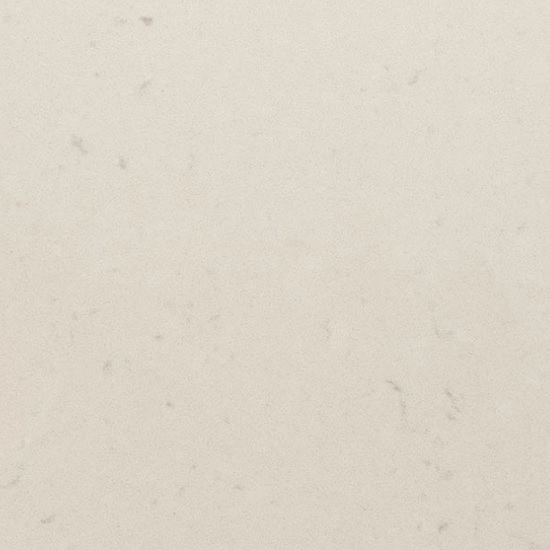

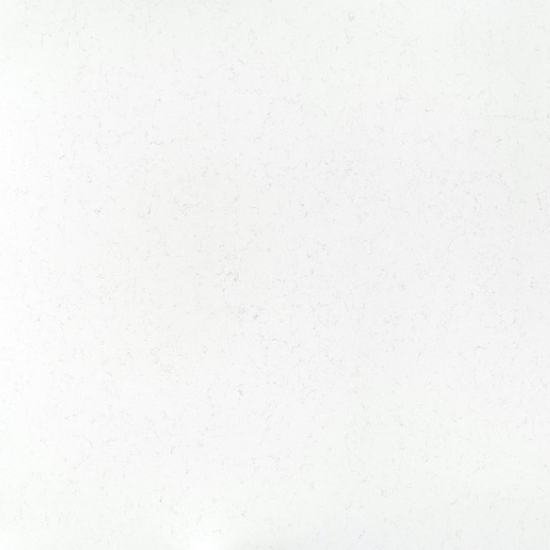

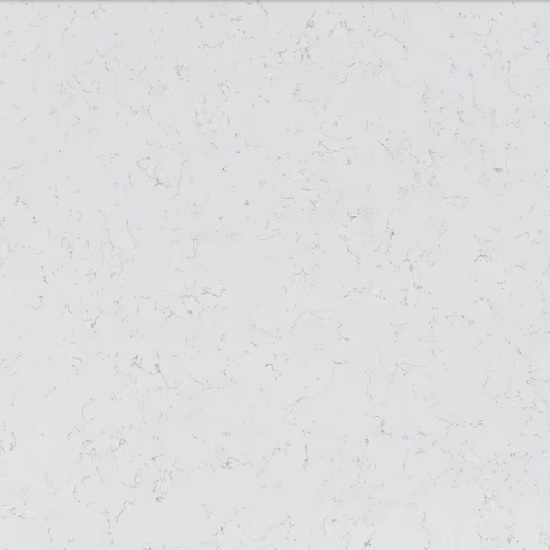

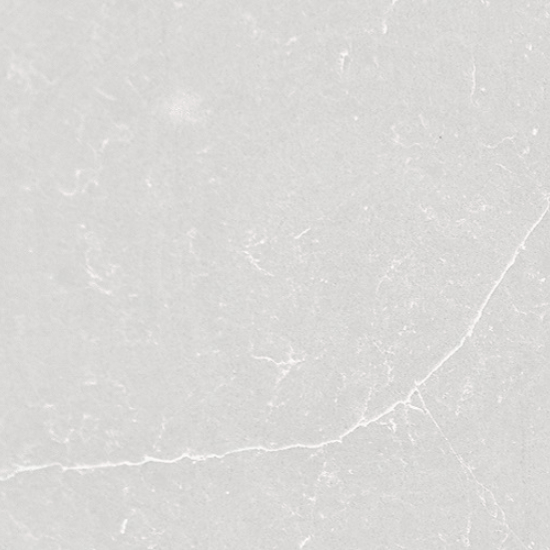

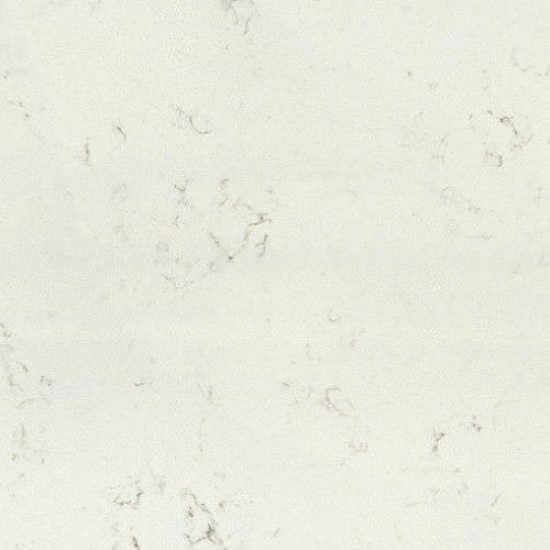

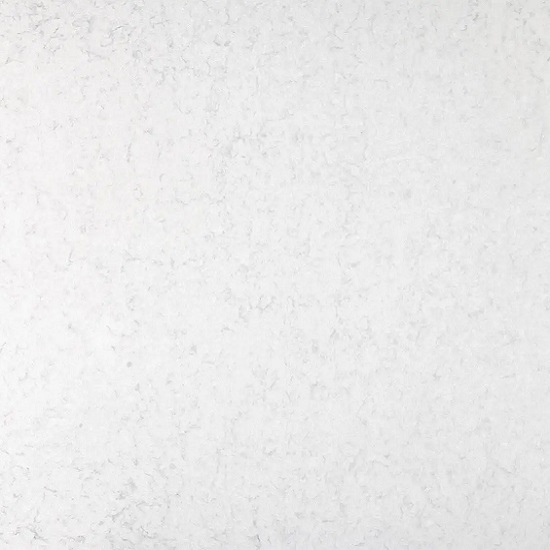

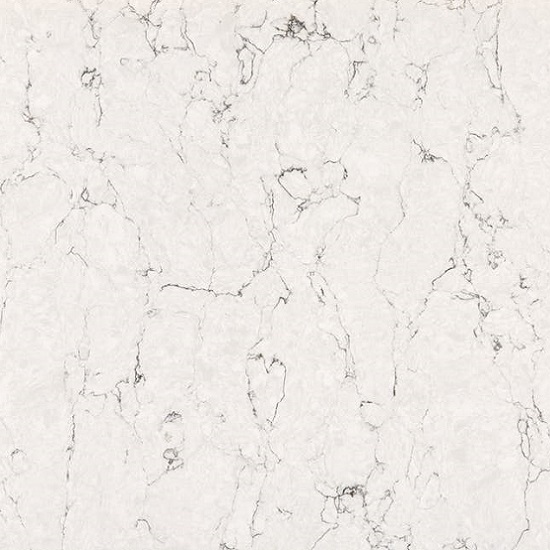

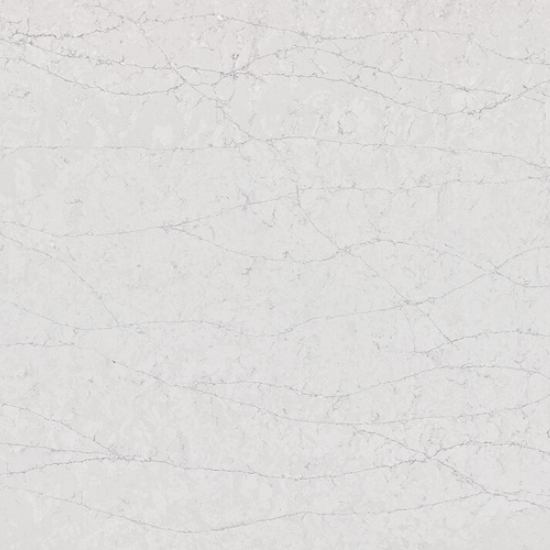

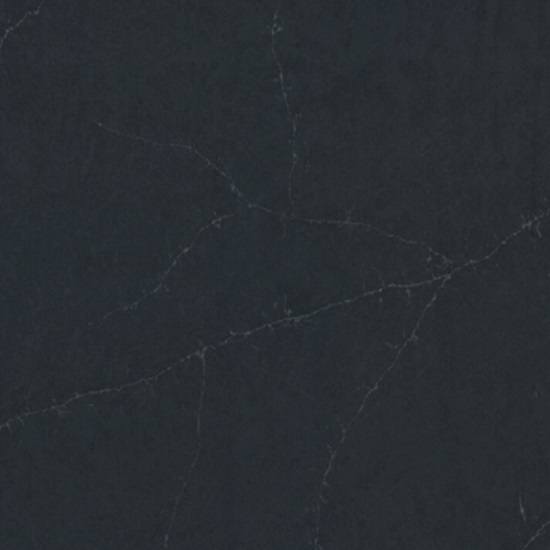

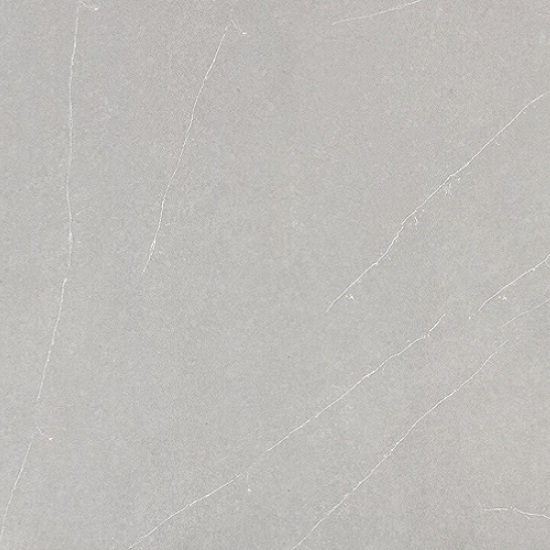

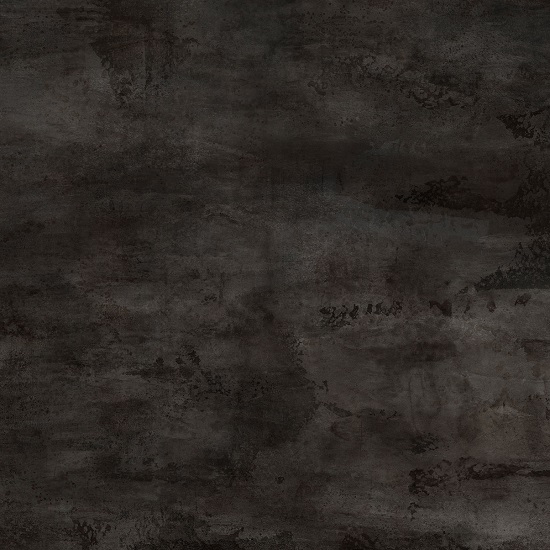

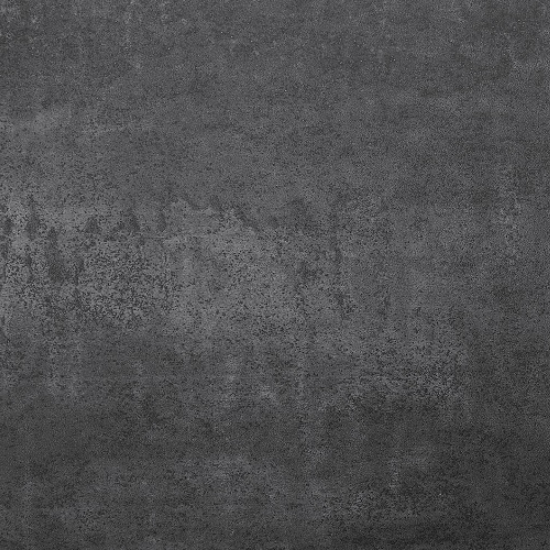

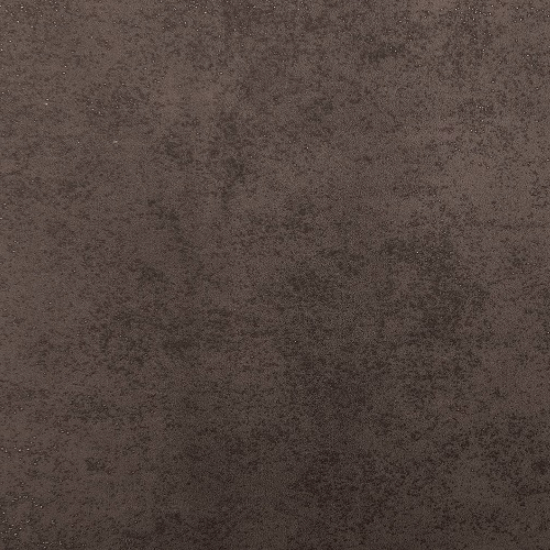

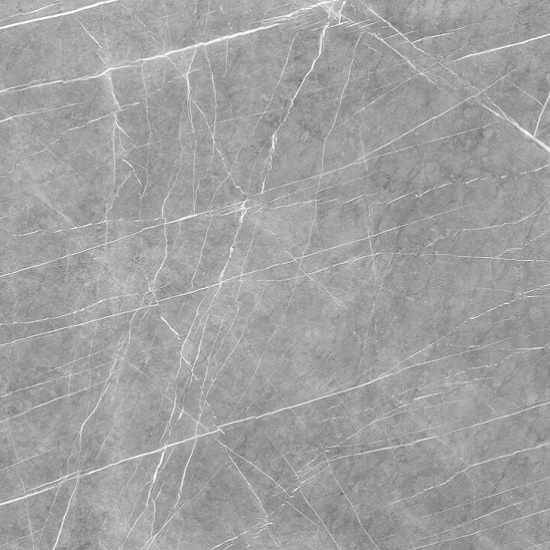

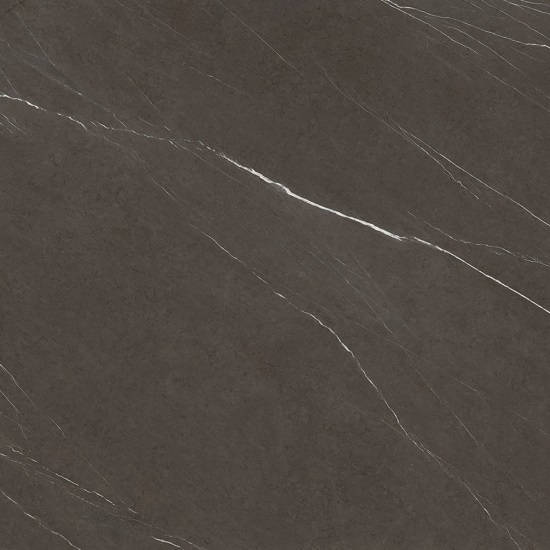

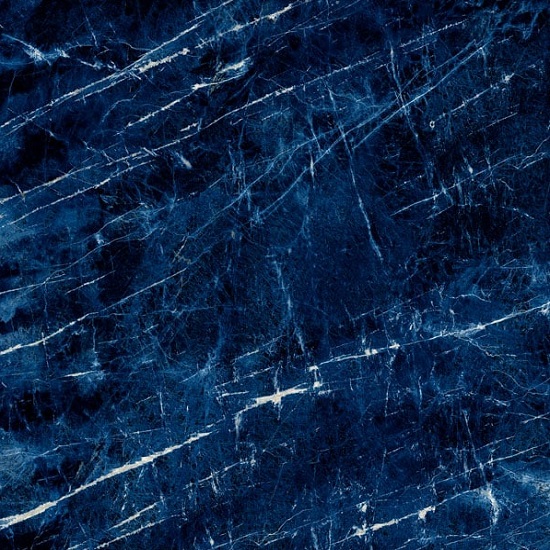

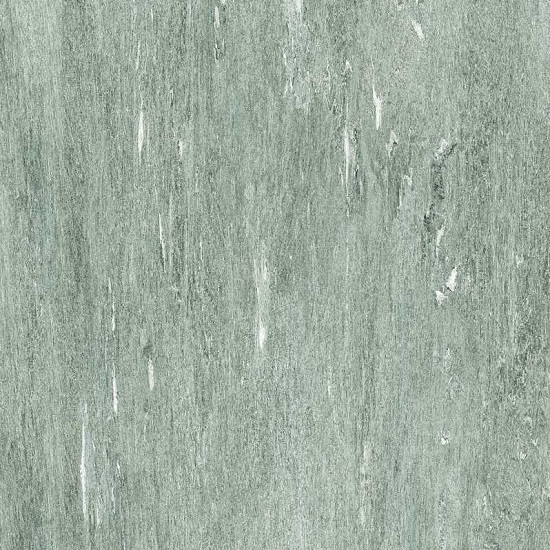

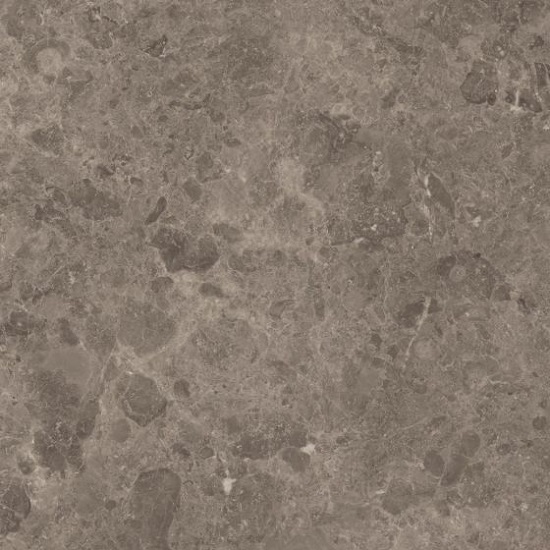

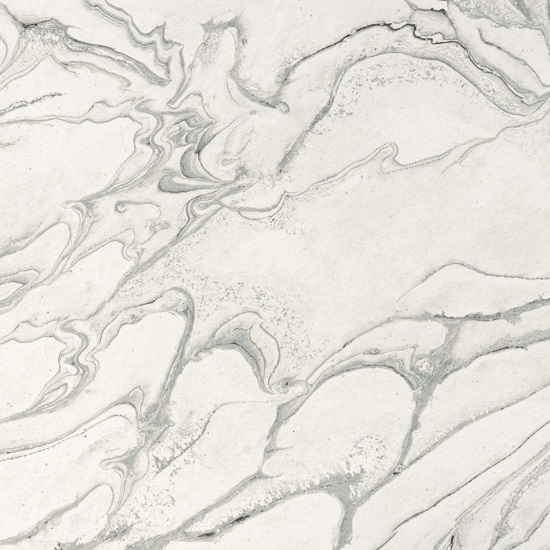

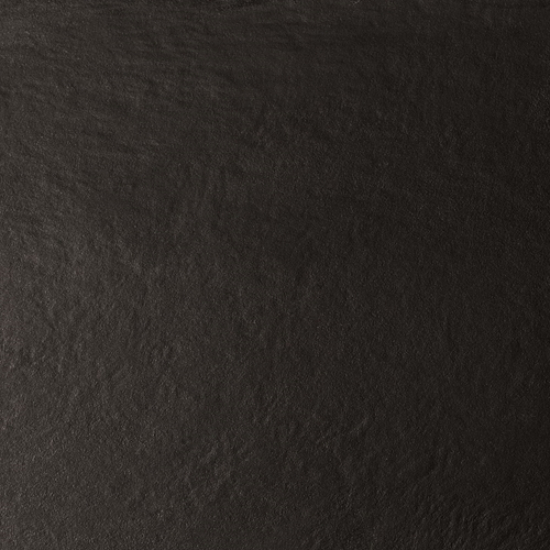

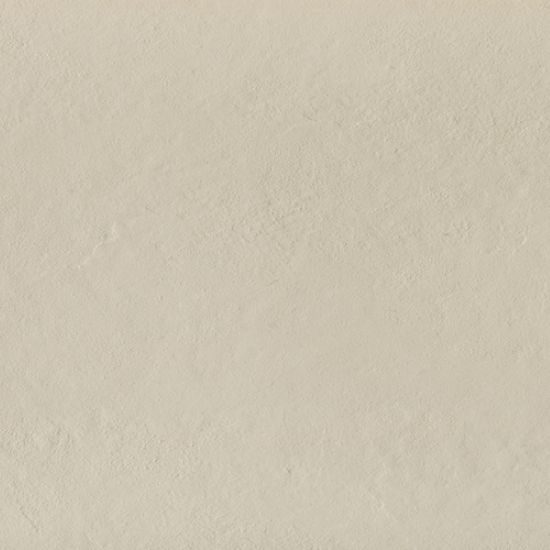

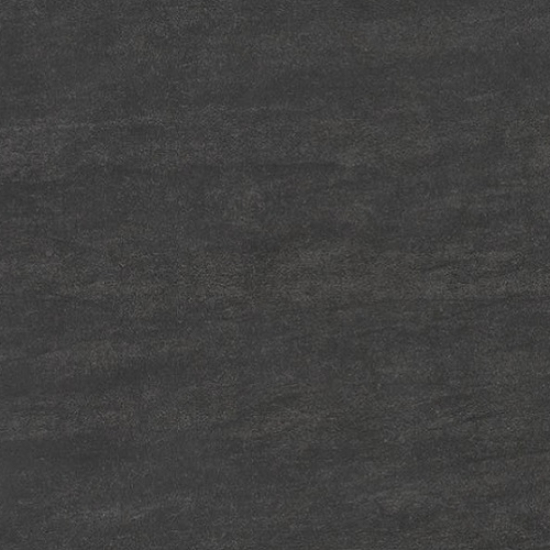

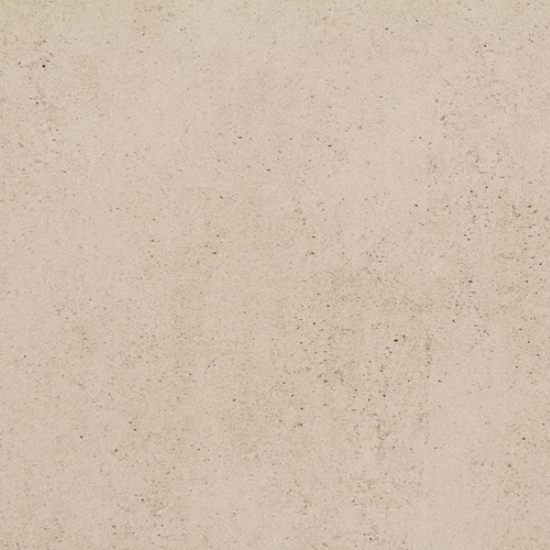

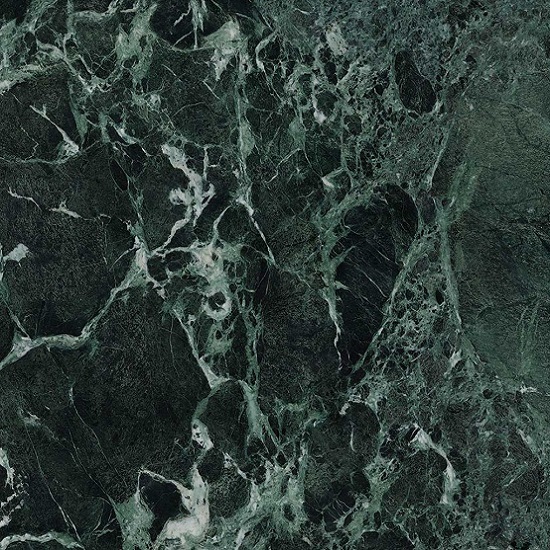

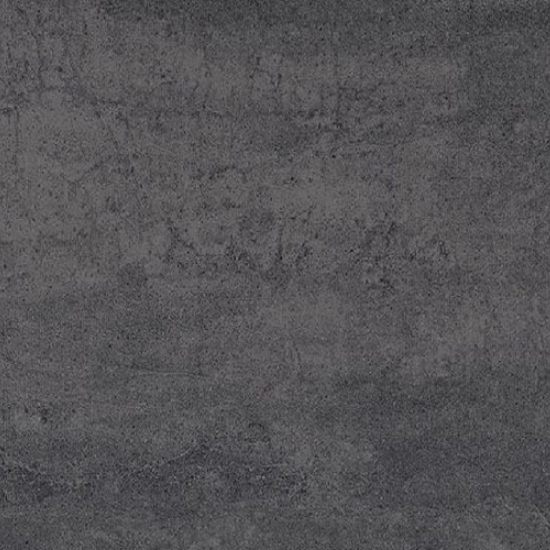

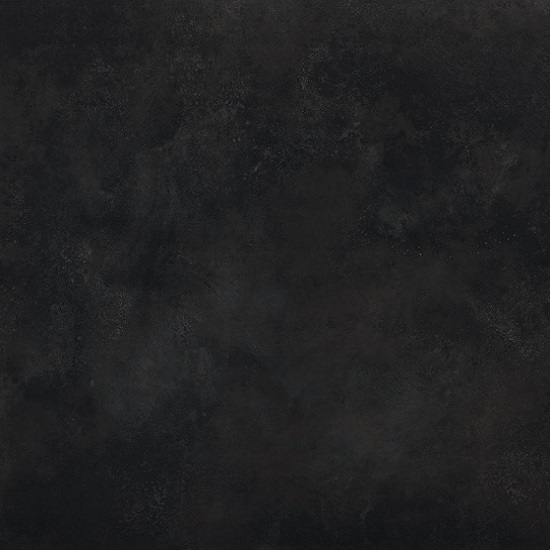

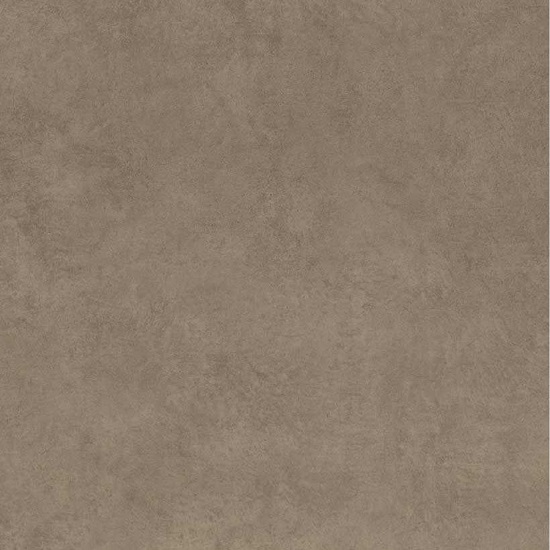

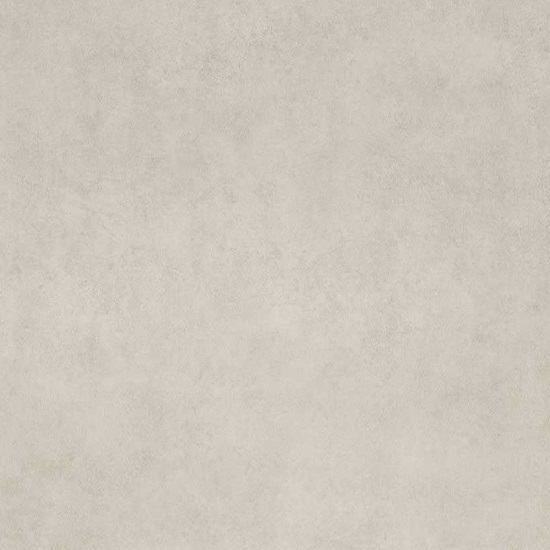

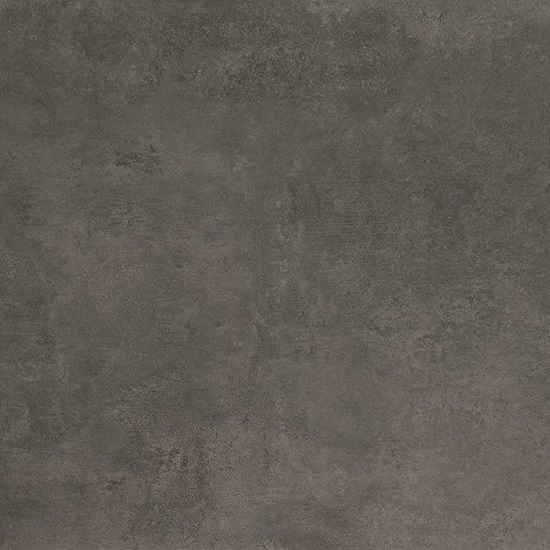

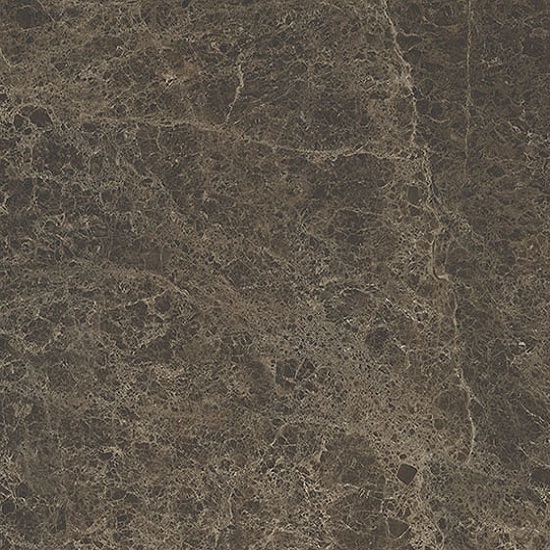

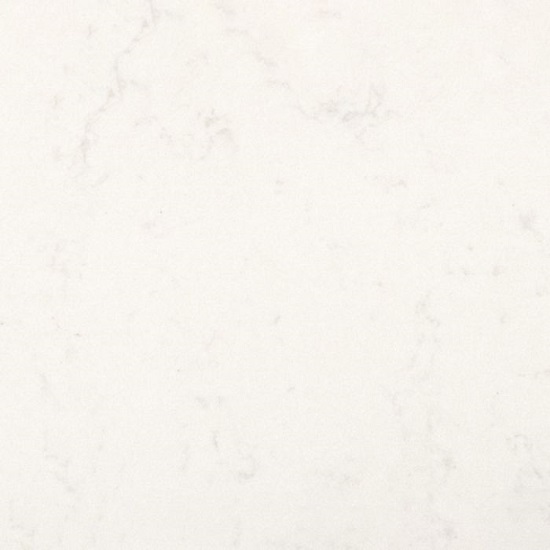

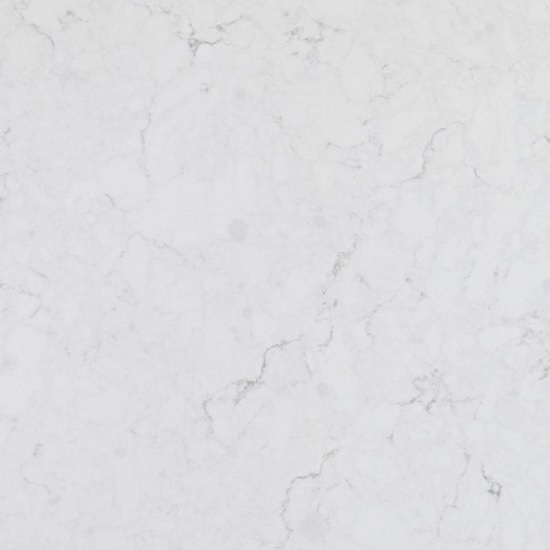

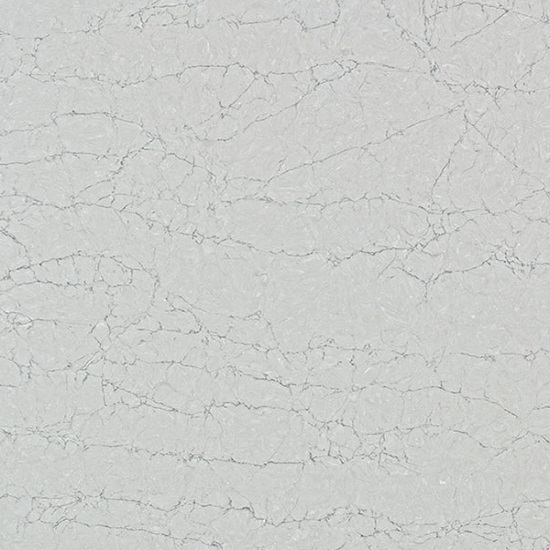

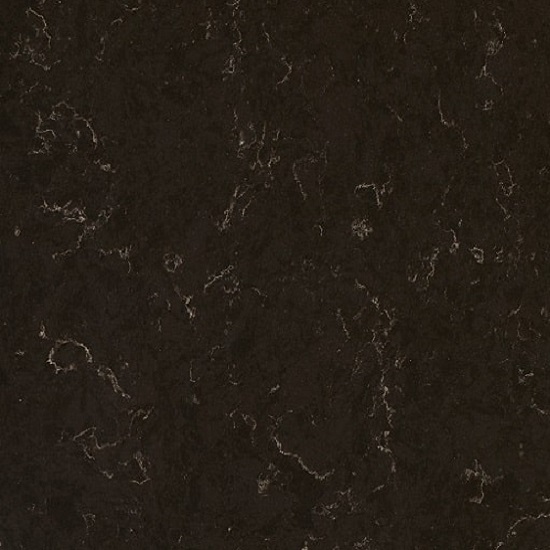

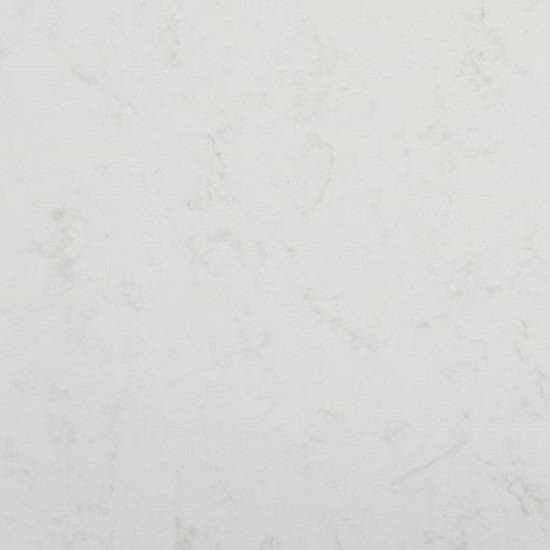

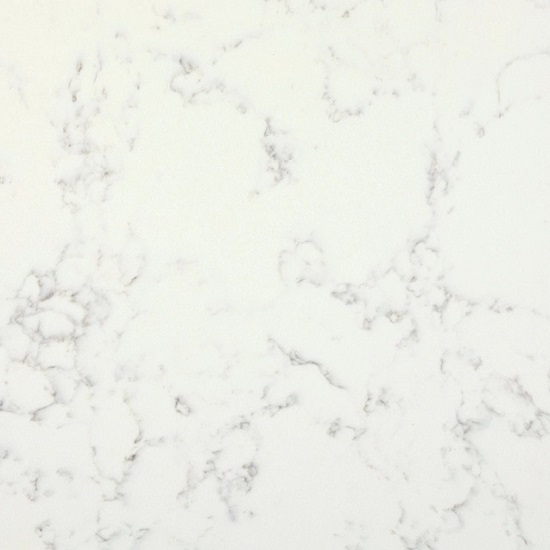

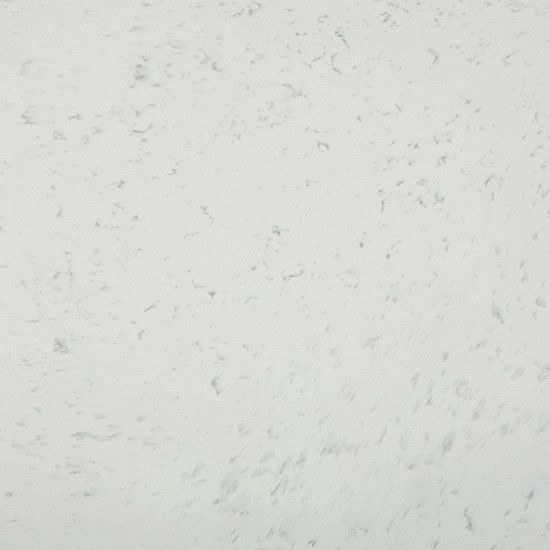

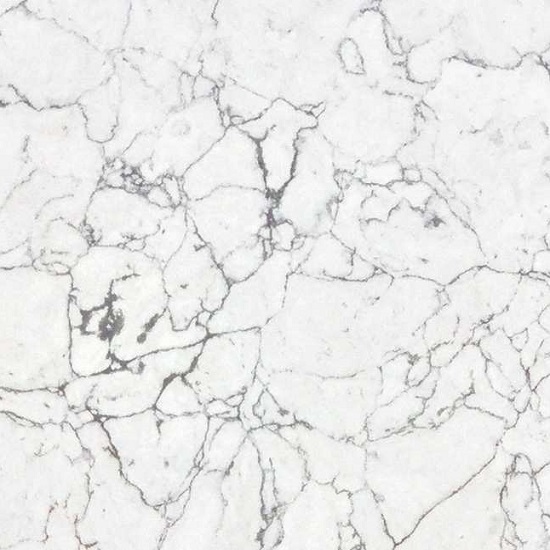

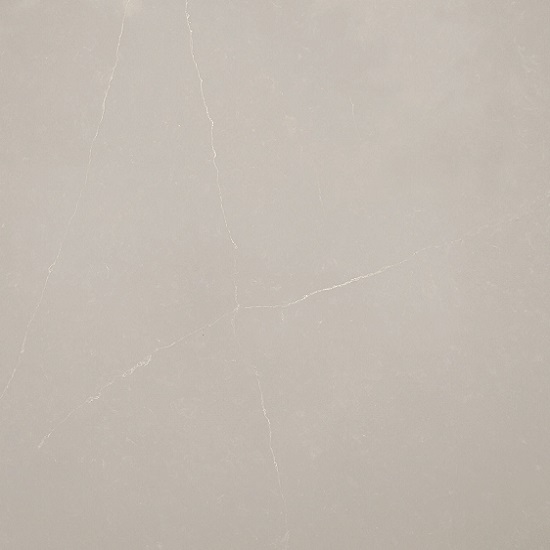

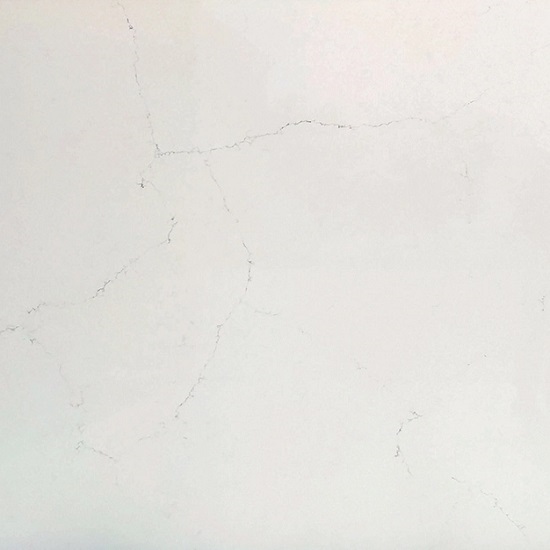

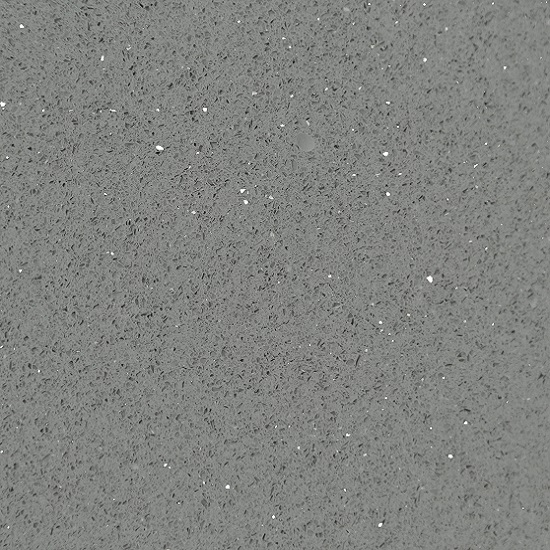

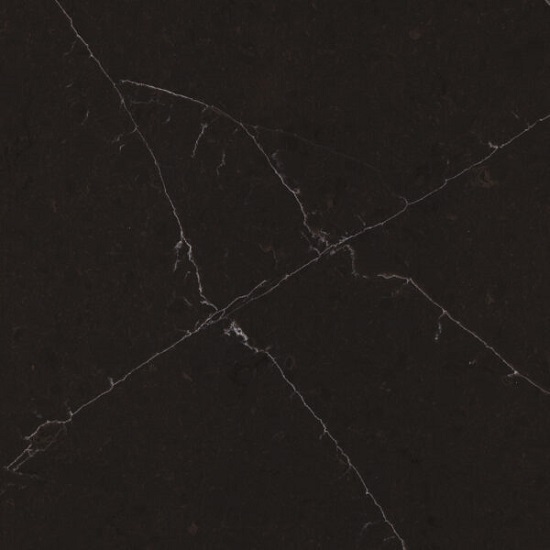

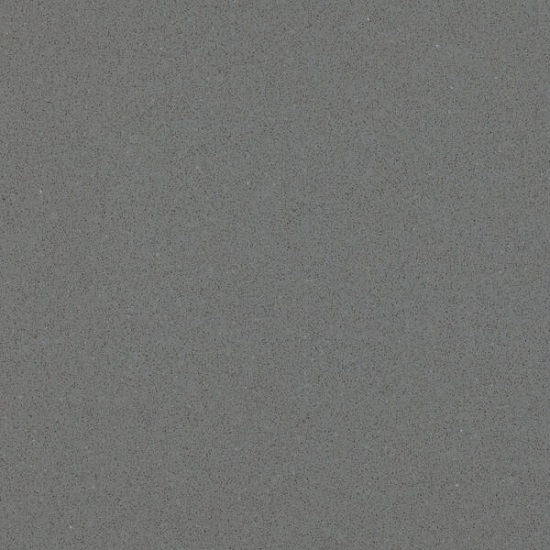

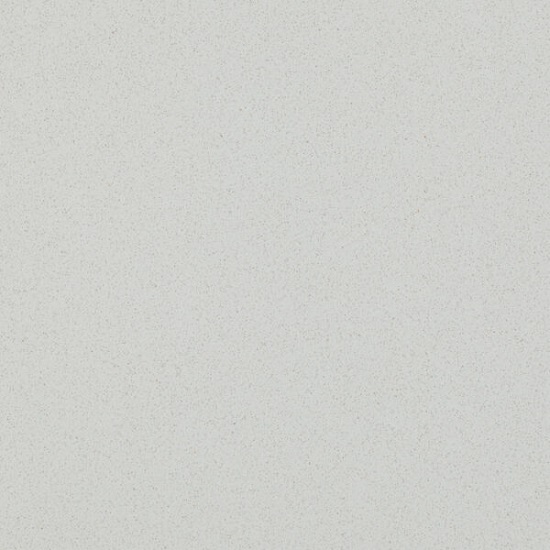

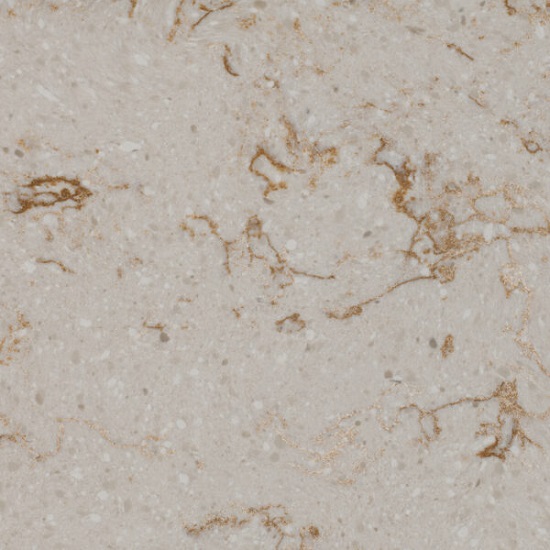

Marazzi Lasa

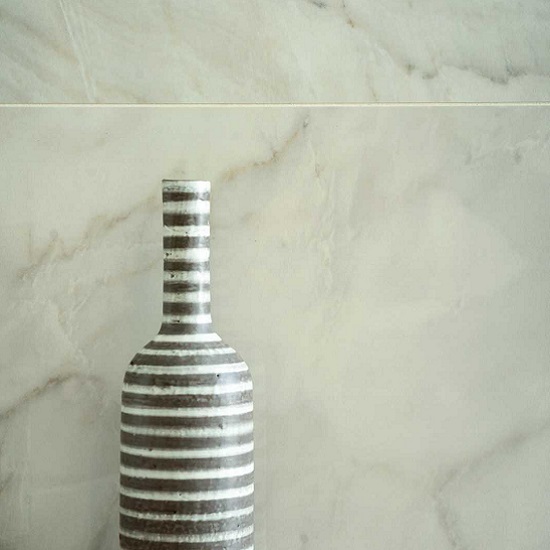

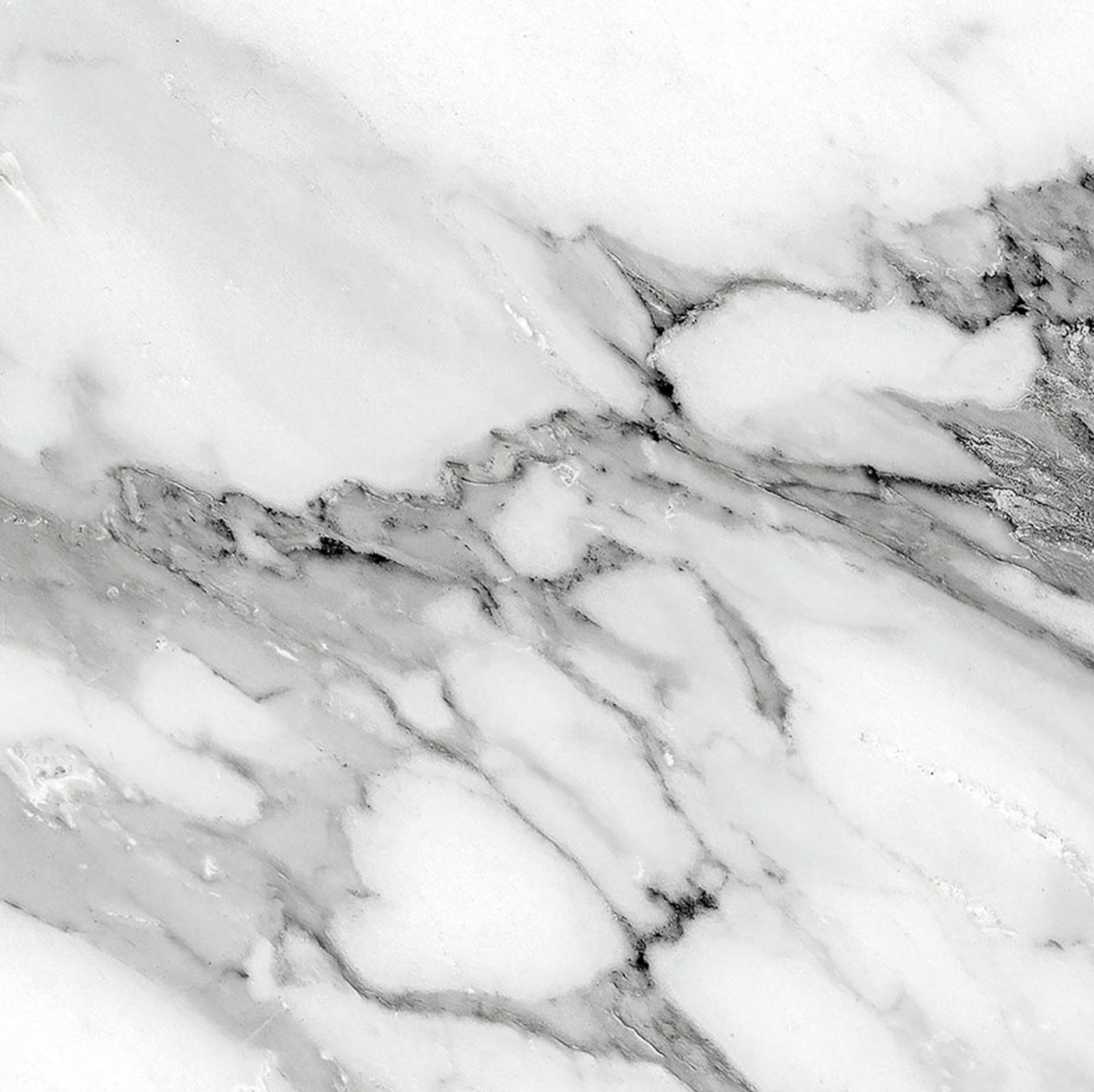

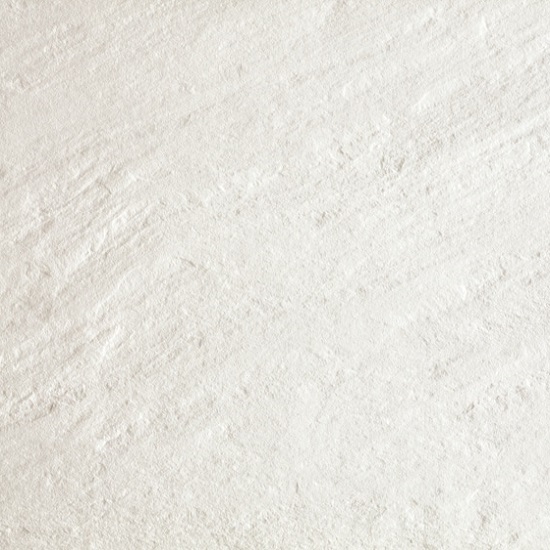

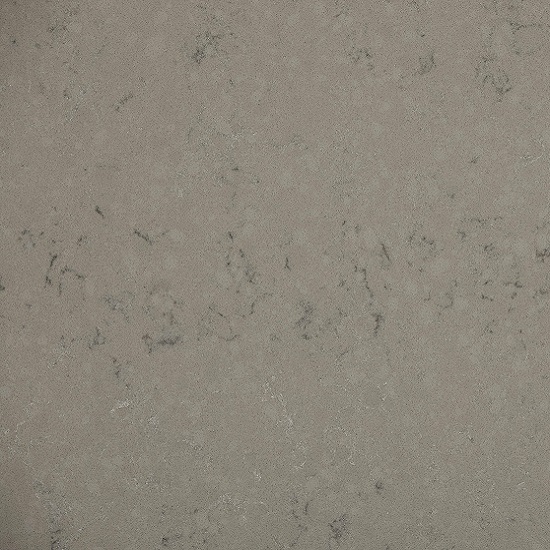

Marazzi Lasa takes inspiration from the 400 million-year-old Bianco Lasa marble from northern Italy, adding the modernity and strength of the ultimate sintered ceramic surface. Read More

Price Rating: £££

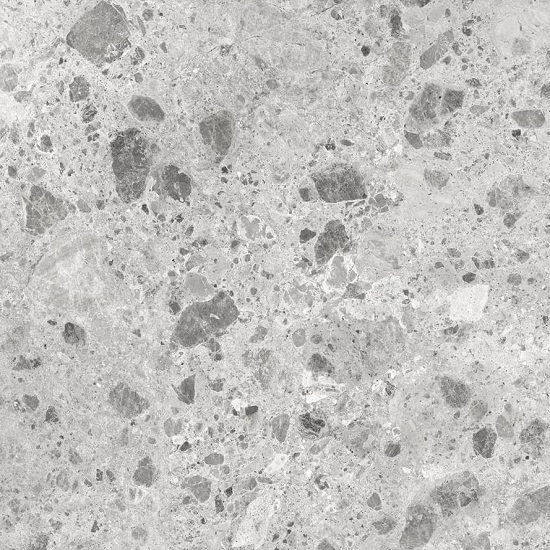

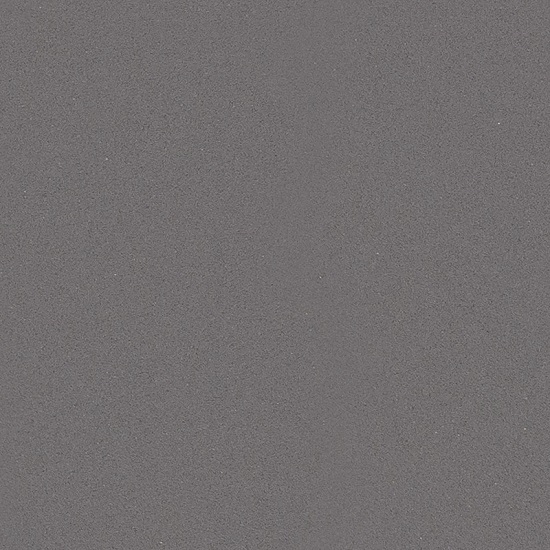

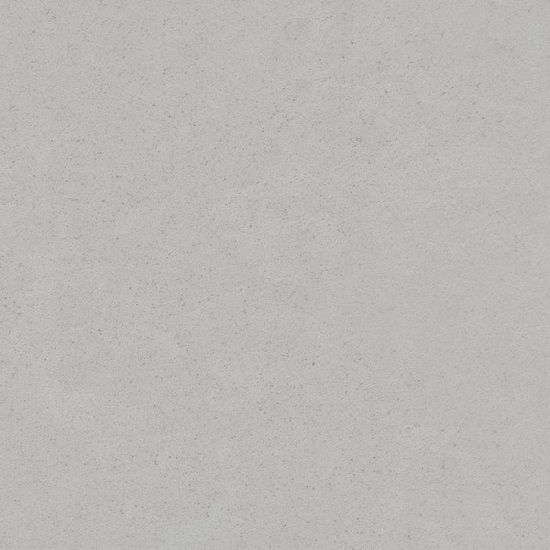

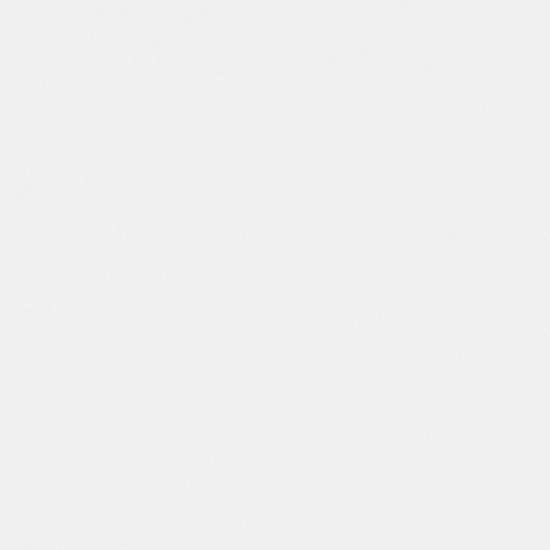

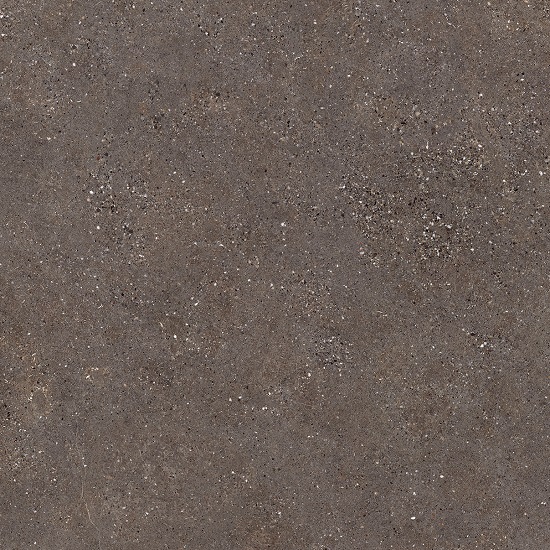

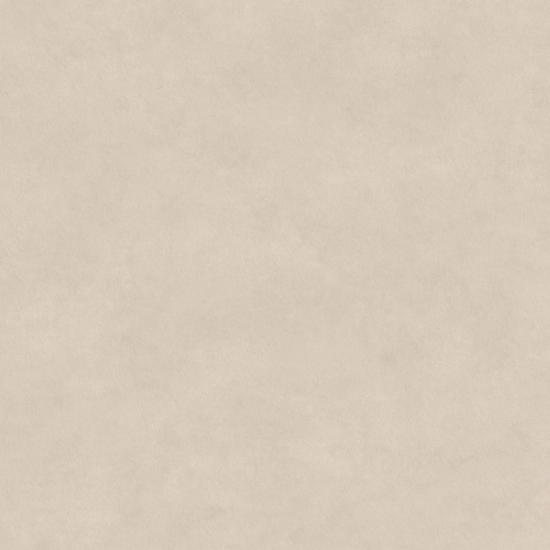

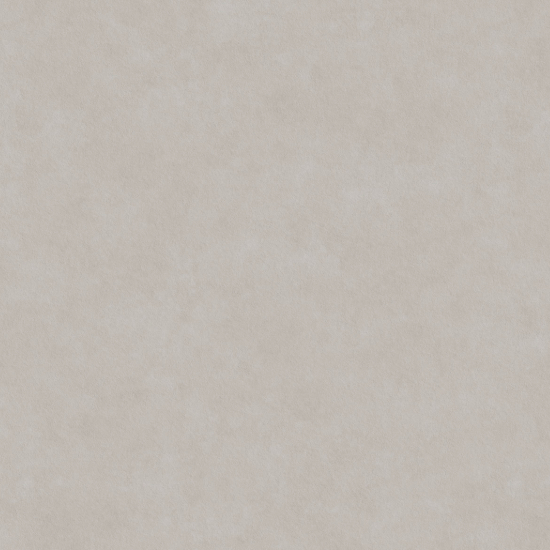

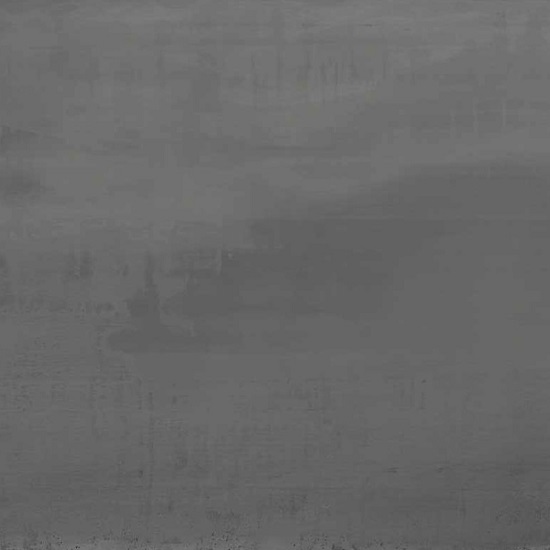

Category : Bathroom Worktops, Commercial Kitchen Worktops, Marazzi The Top Worktops, Options Worktops 12mm, Porcelain Worktops

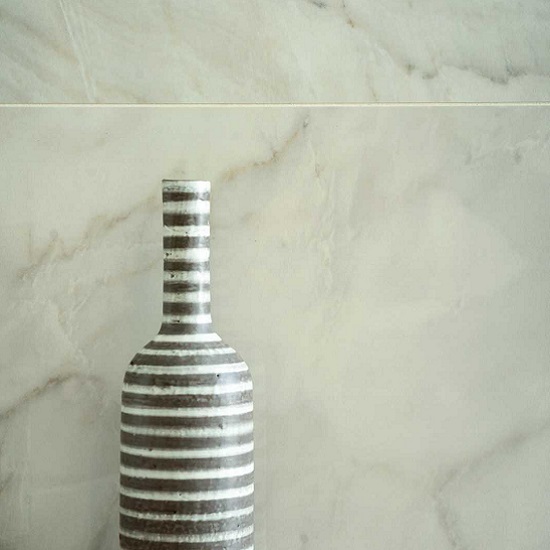

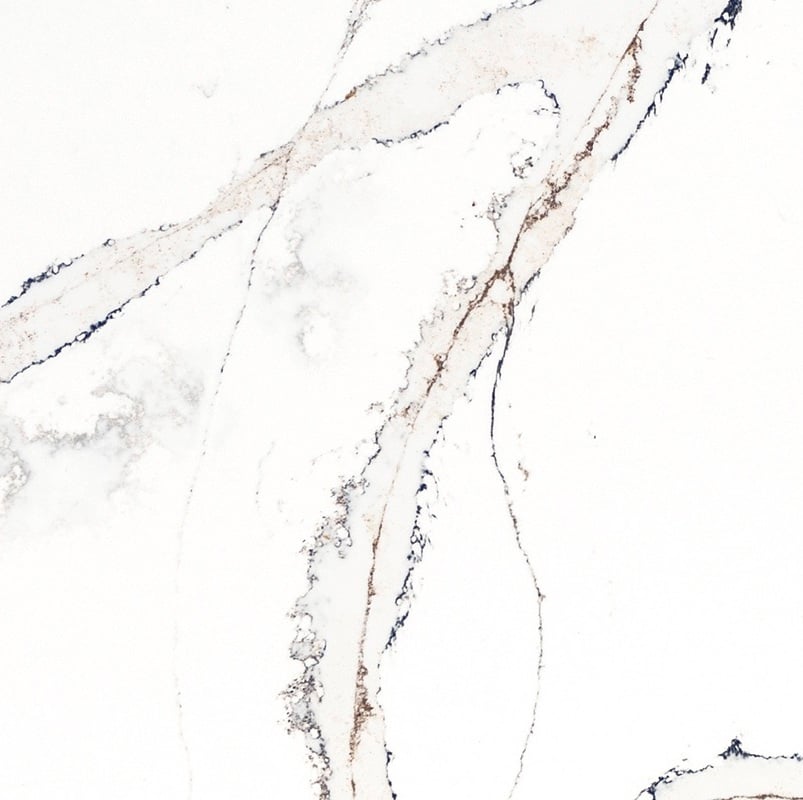

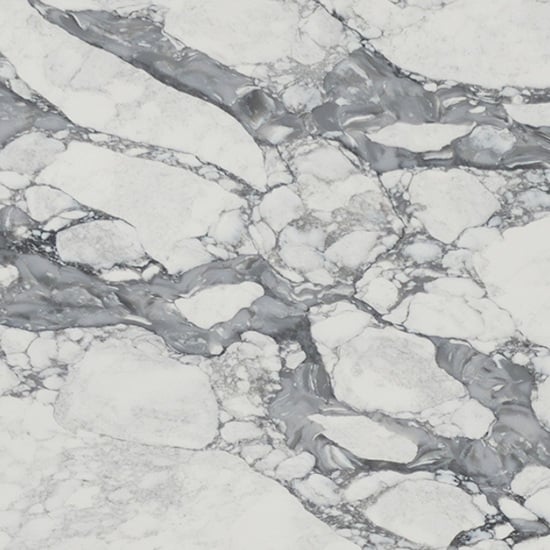

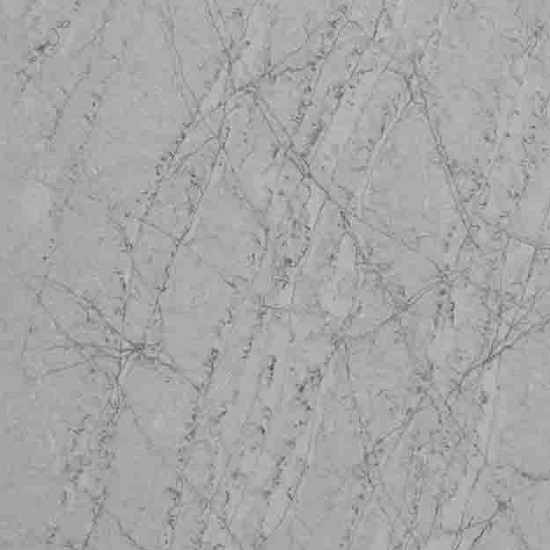

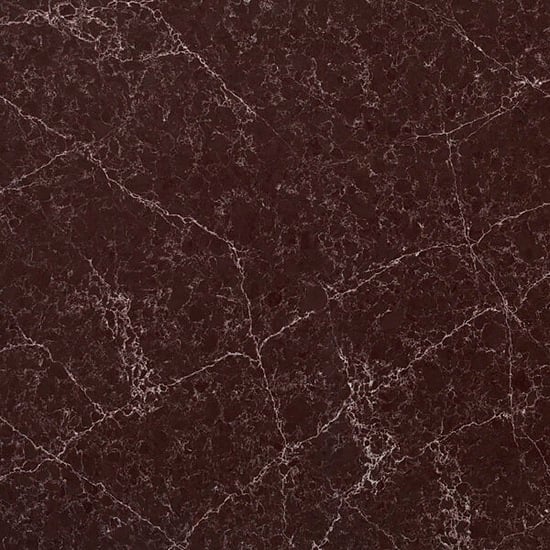

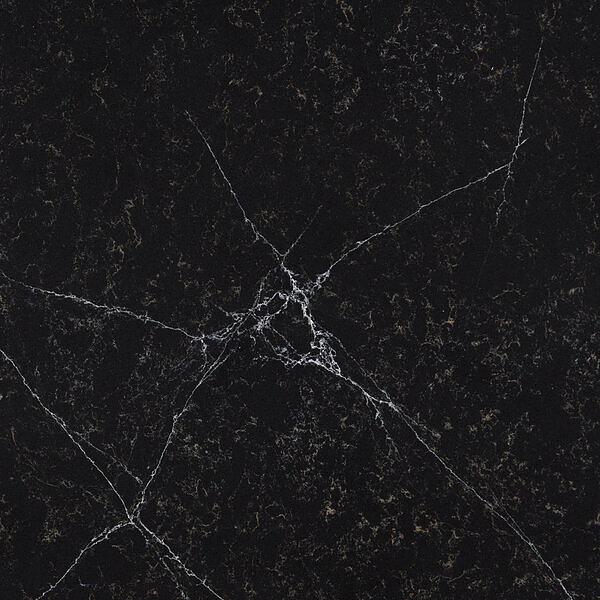

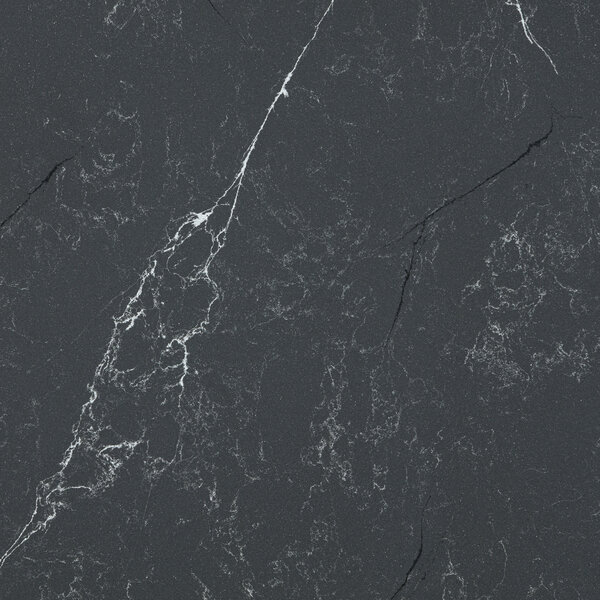

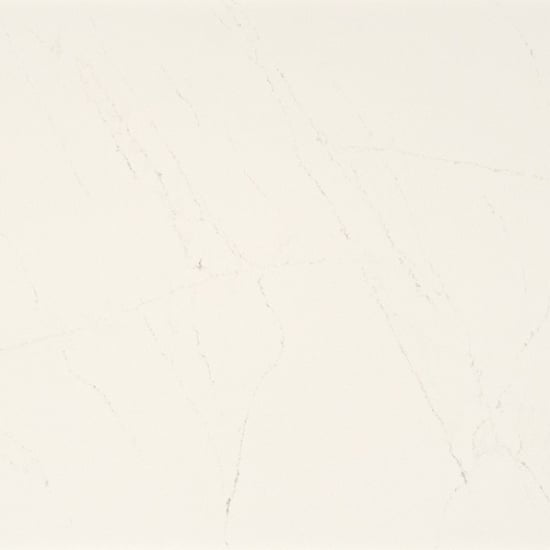

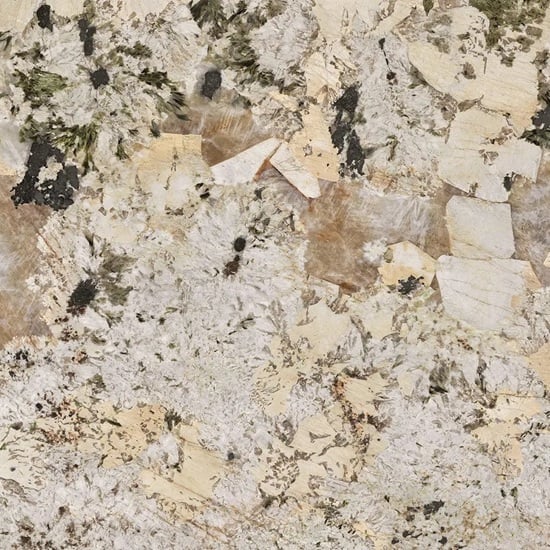

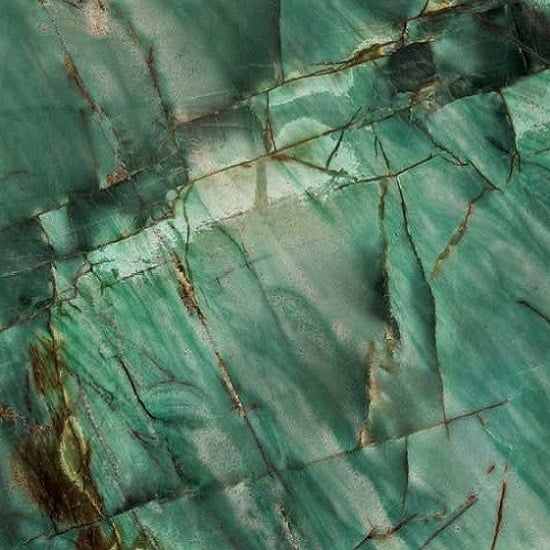

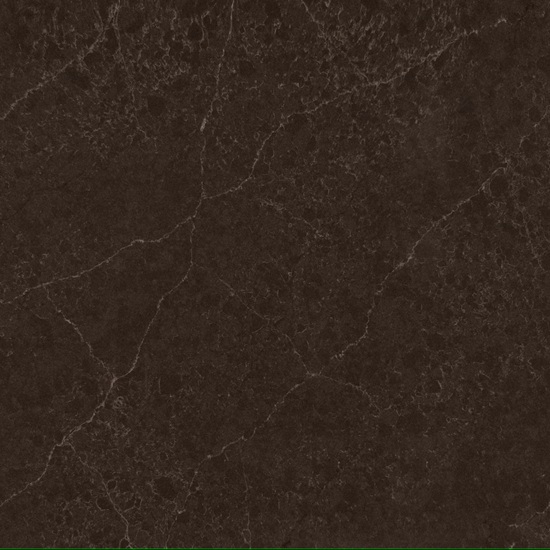

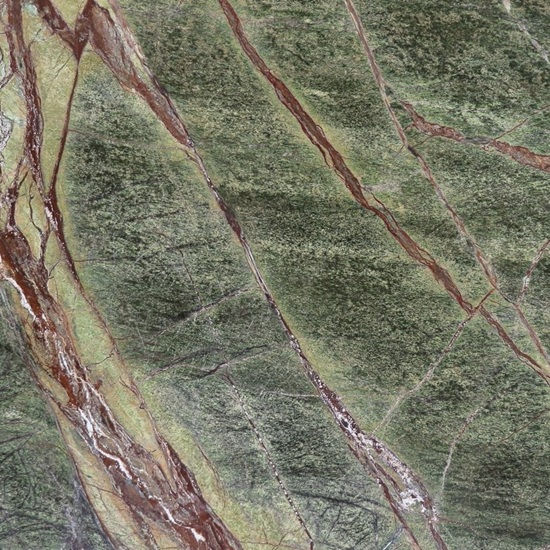

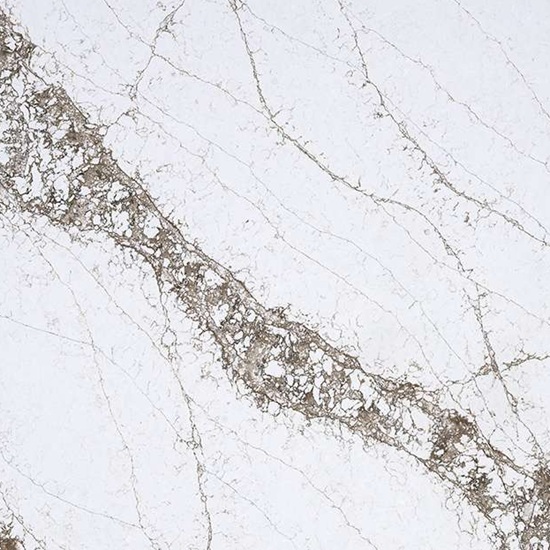

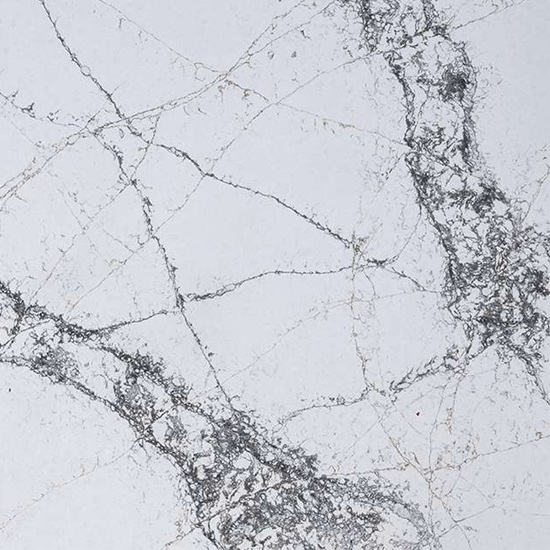

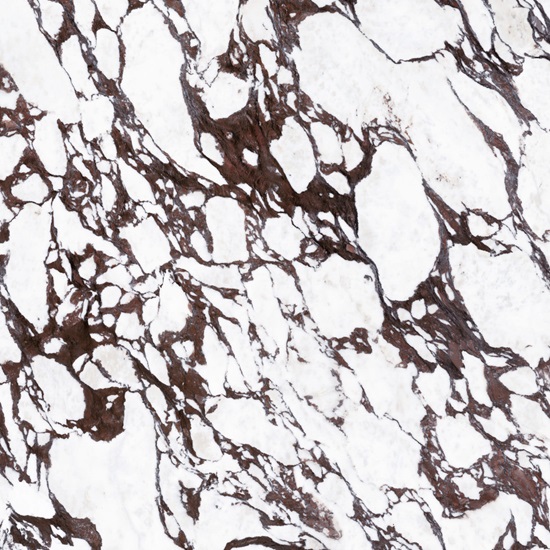

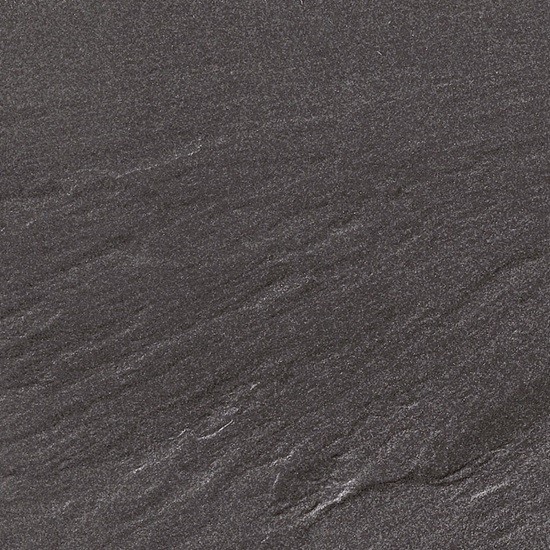

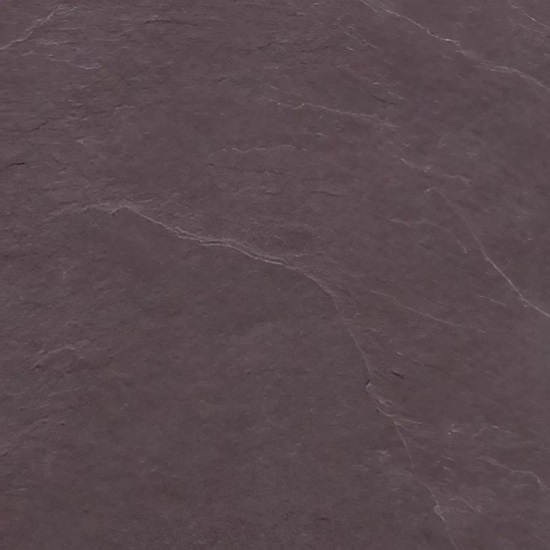

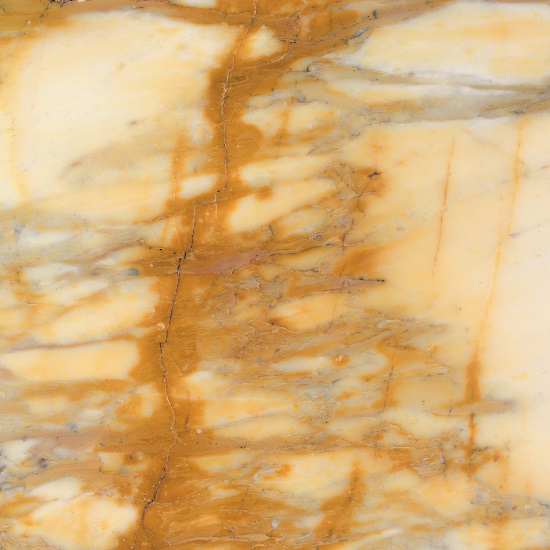

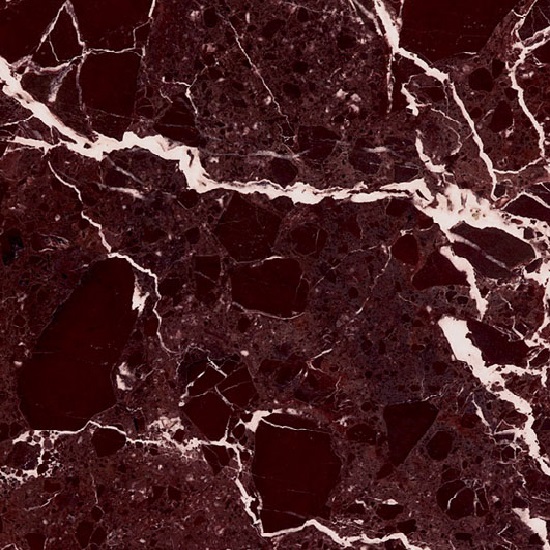

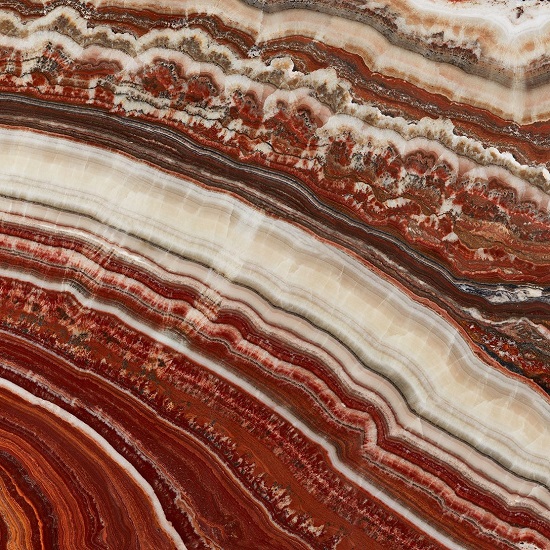

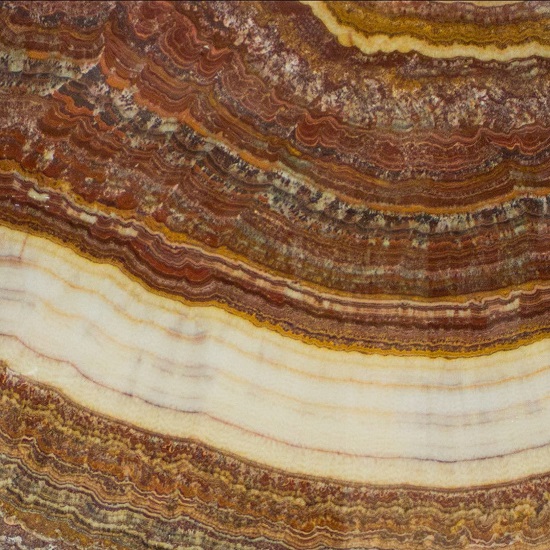

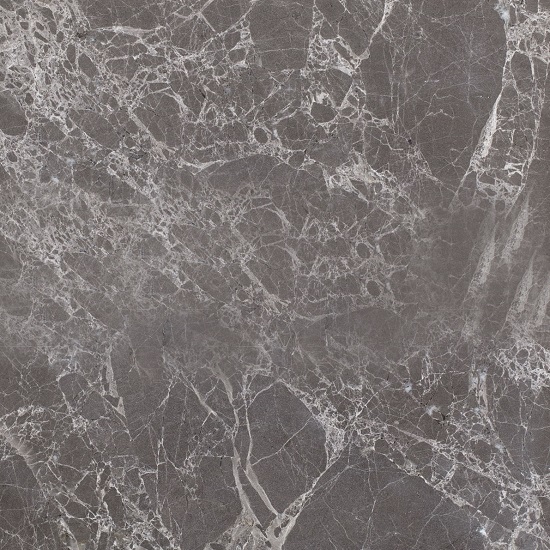

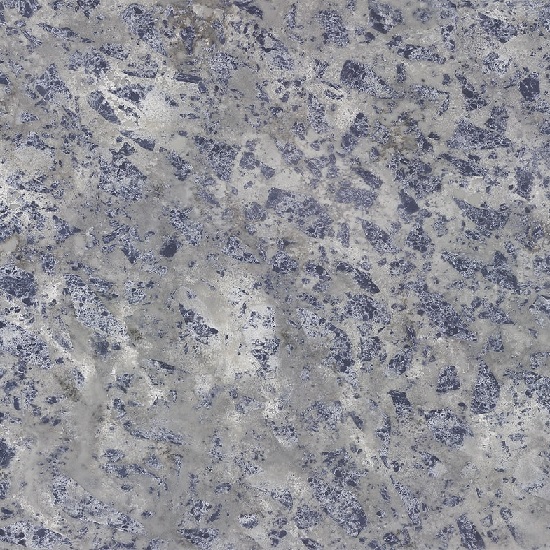

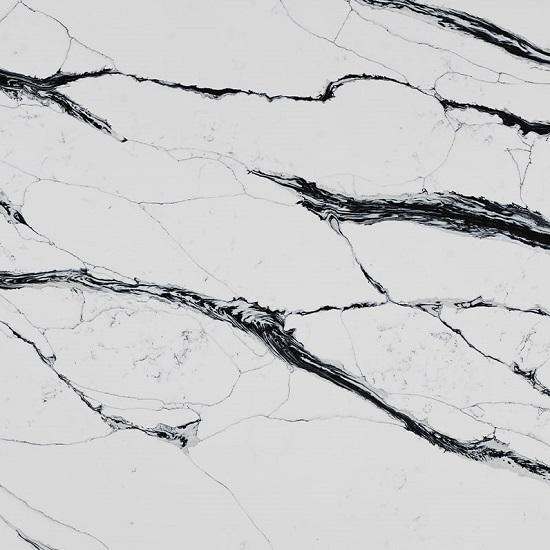

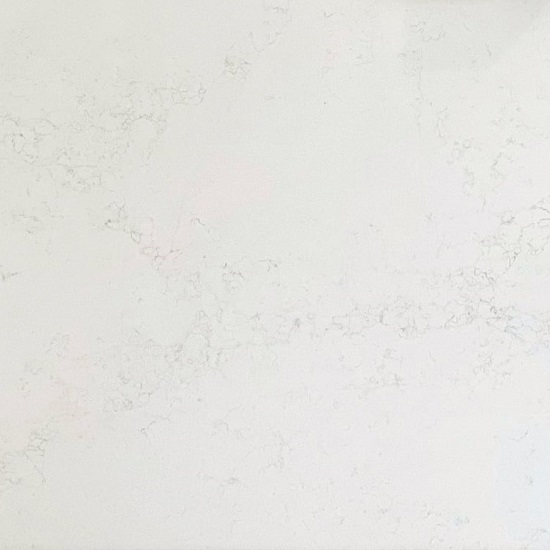

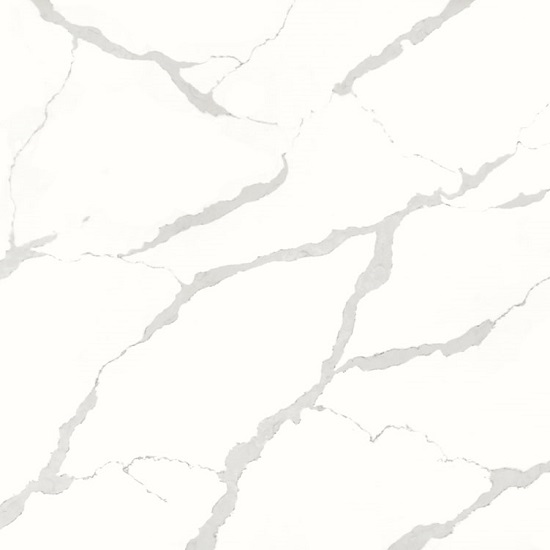

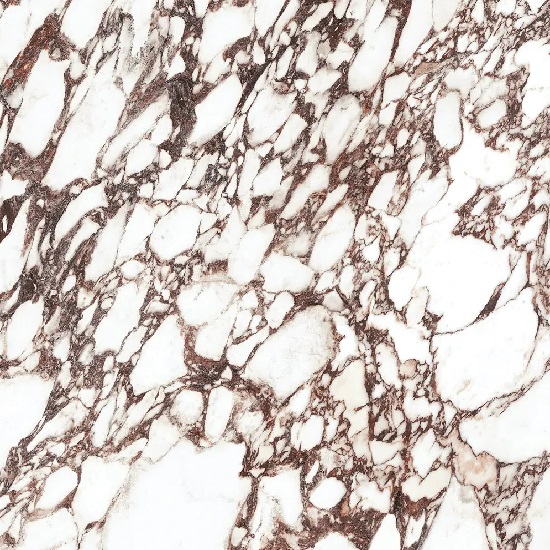

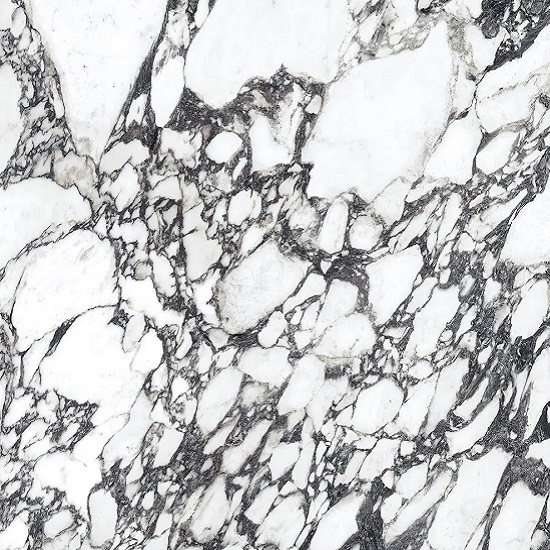

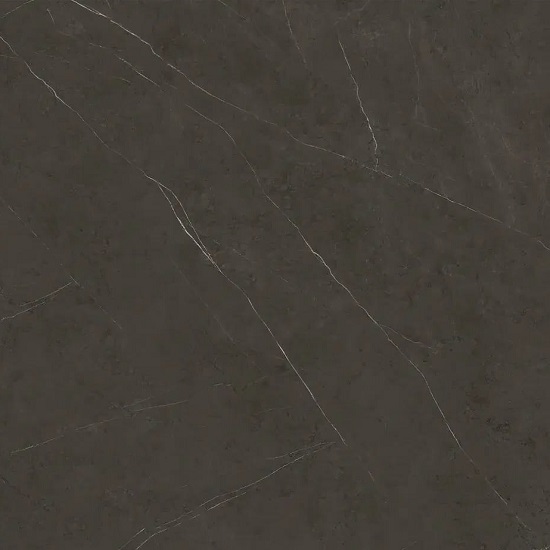

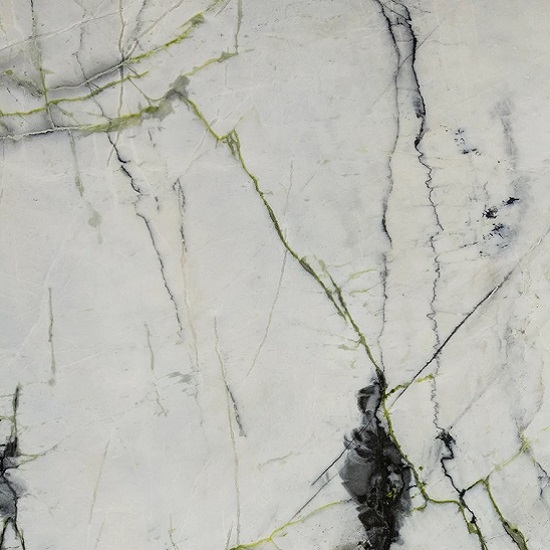

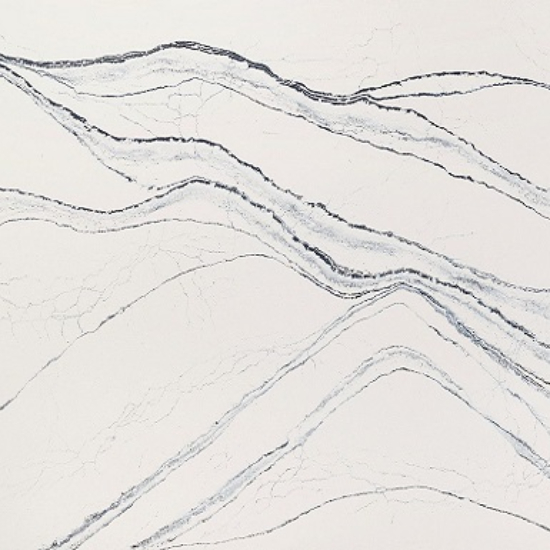

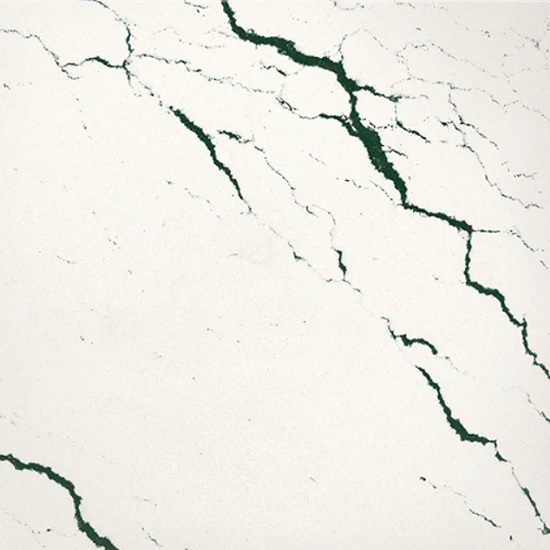

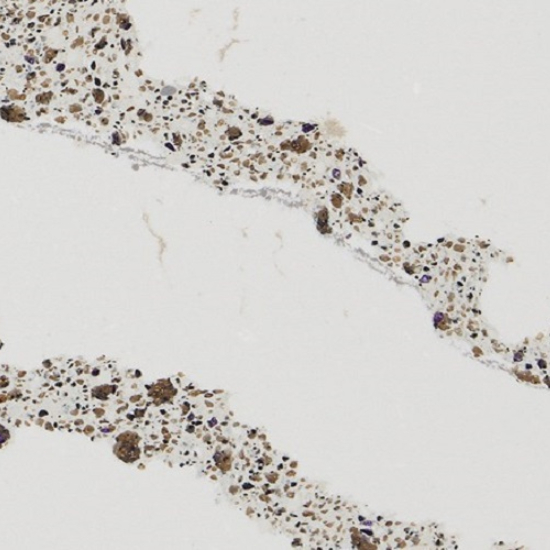

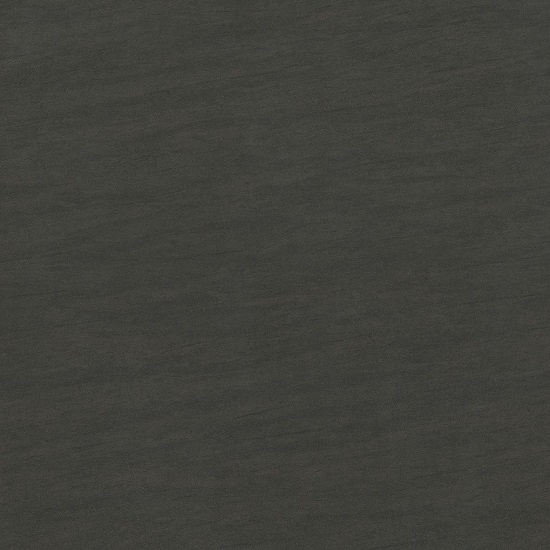

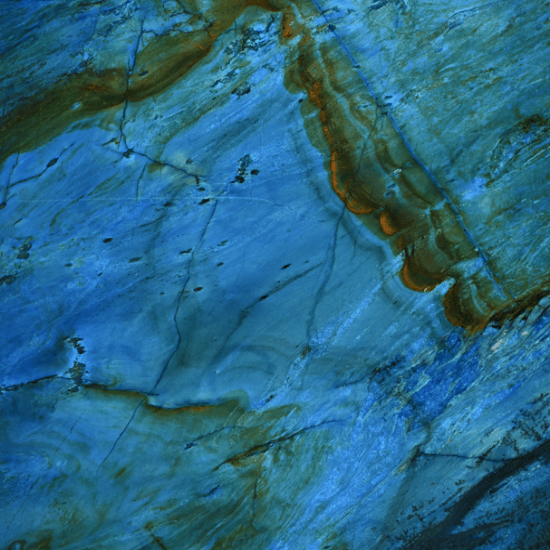

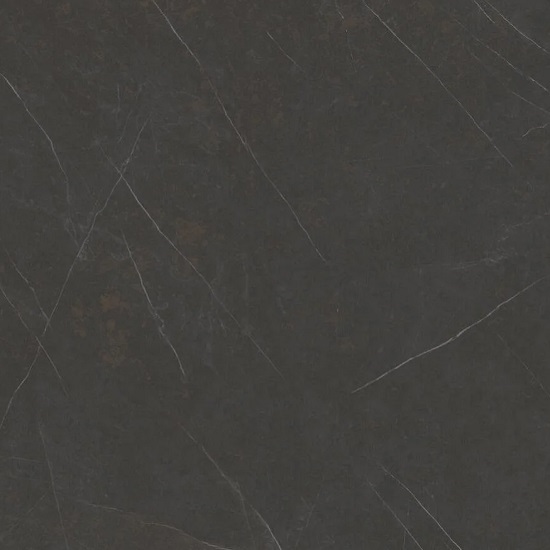

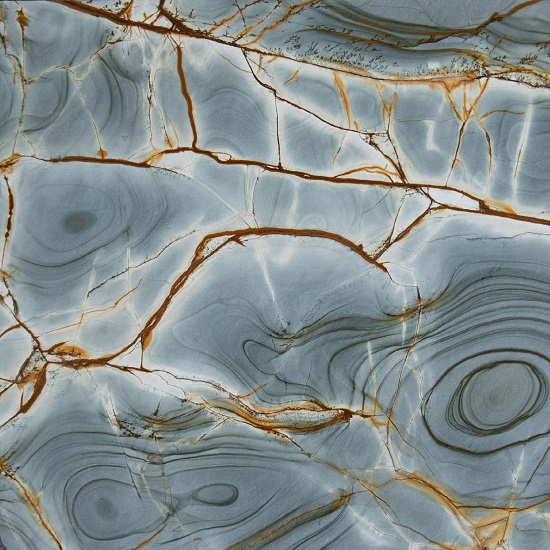

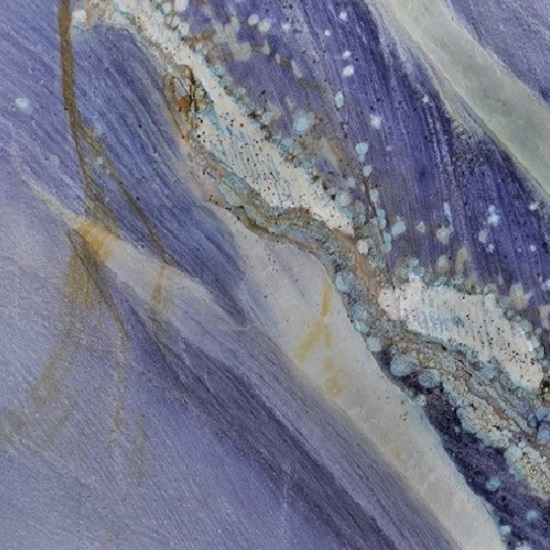

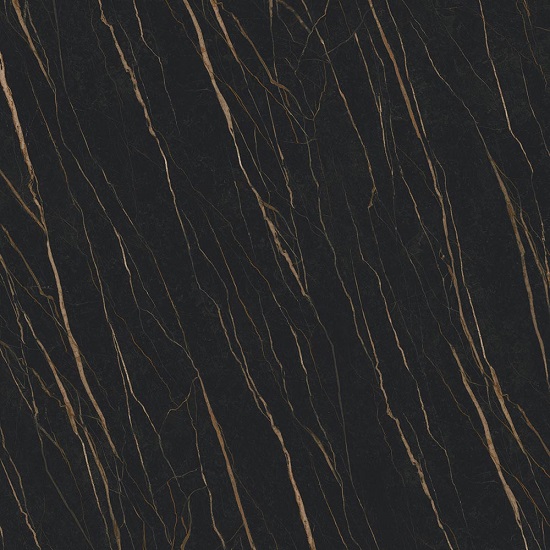

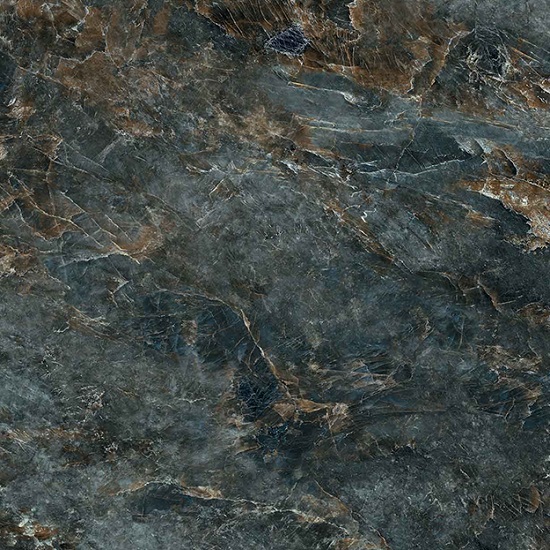

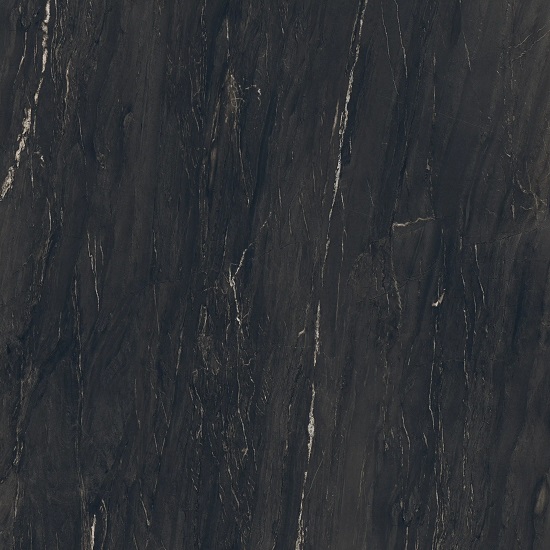

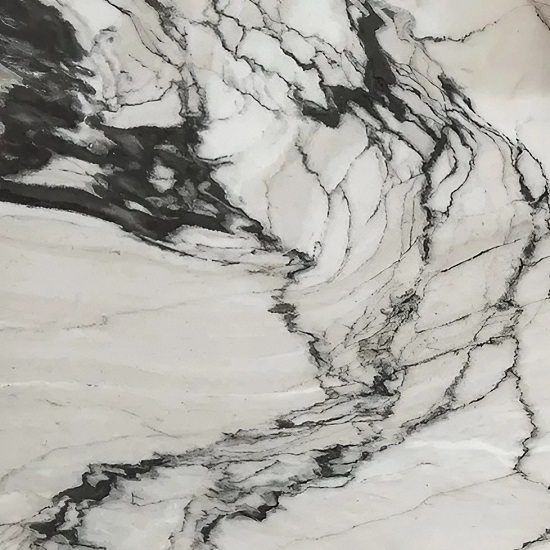

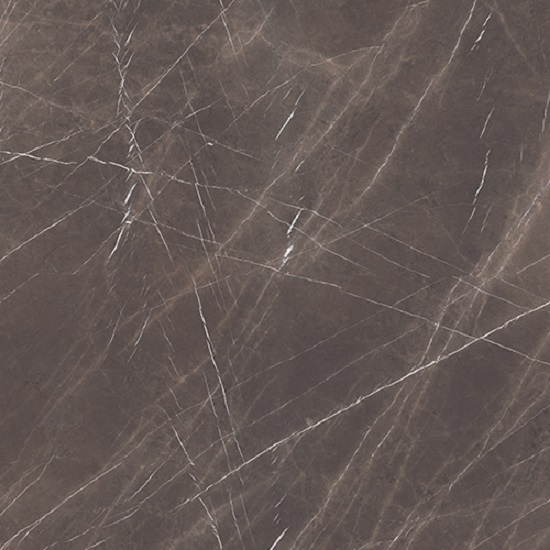

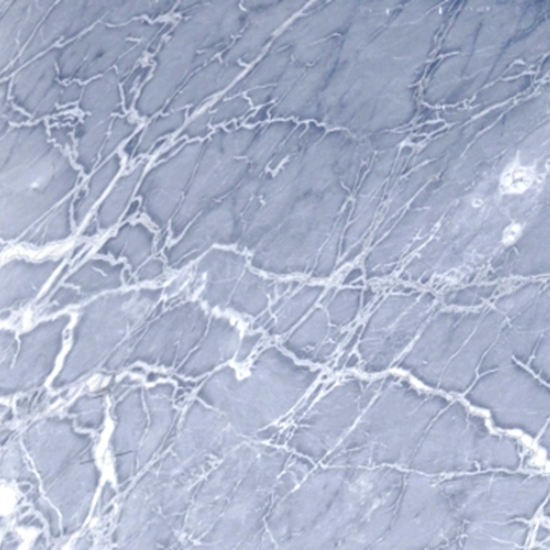

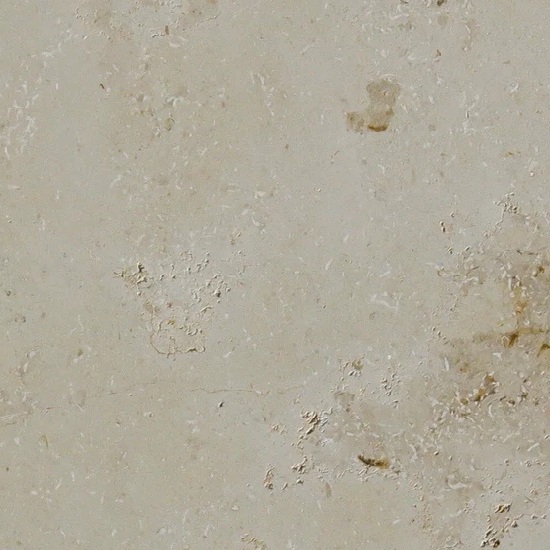

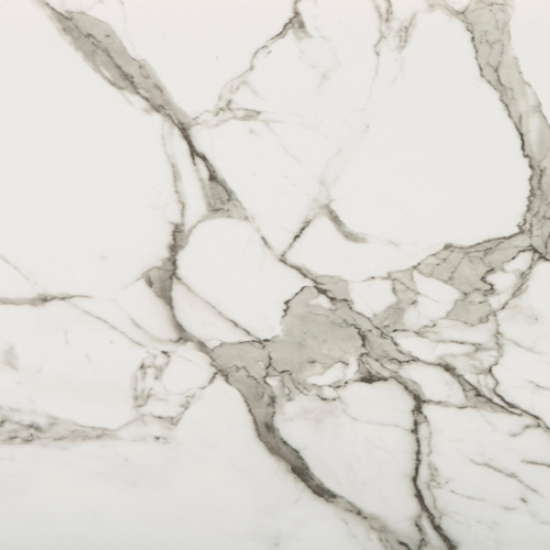

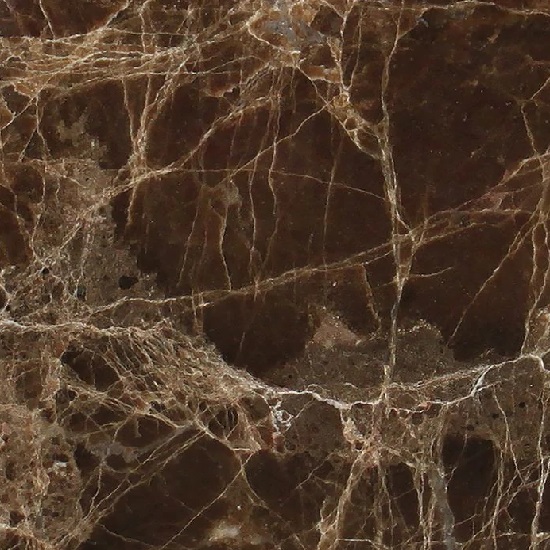

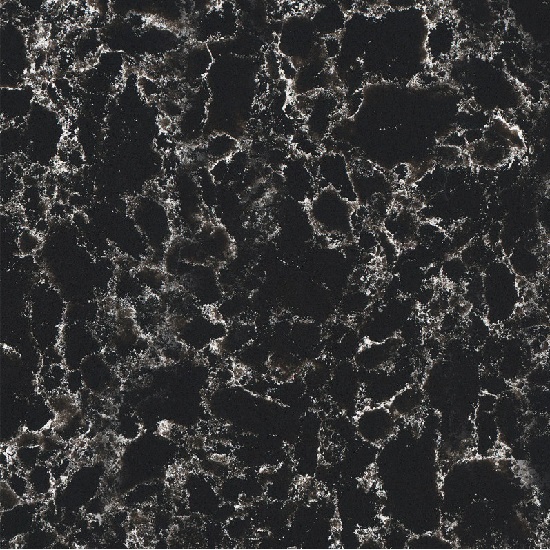

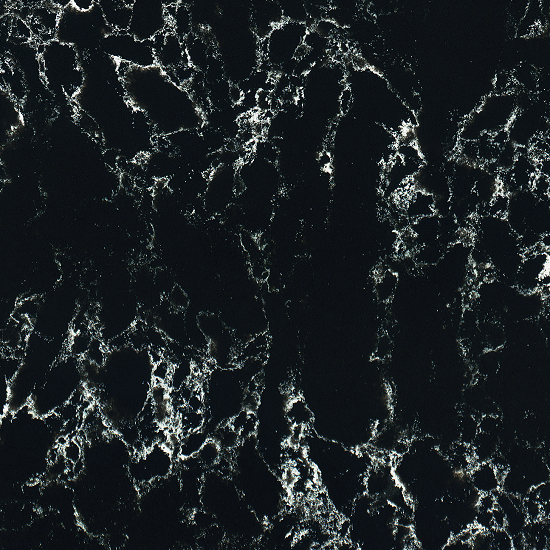

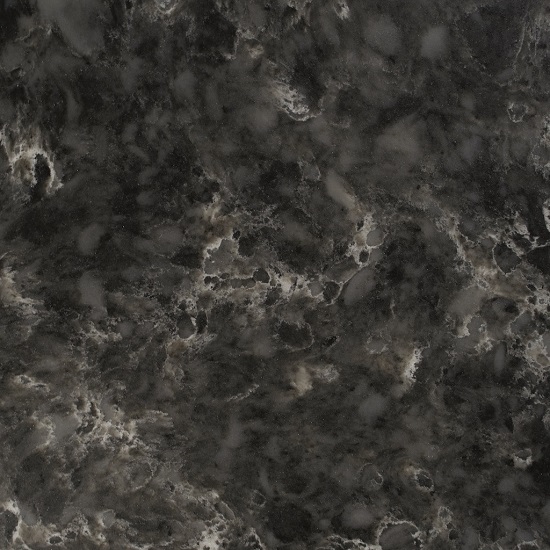

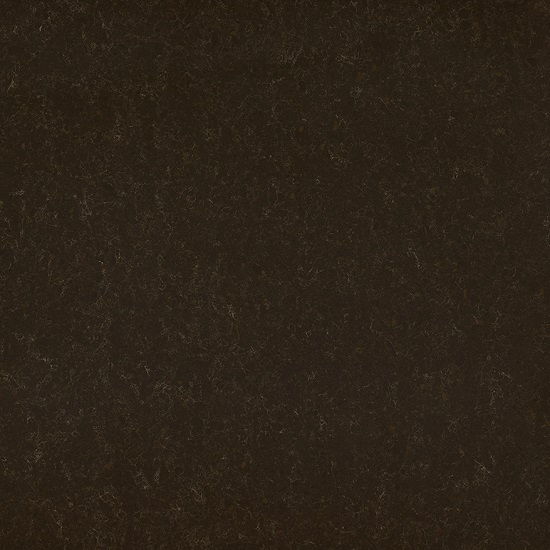

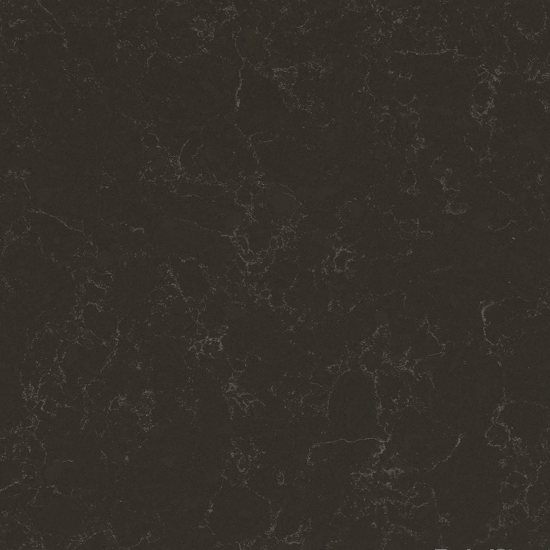

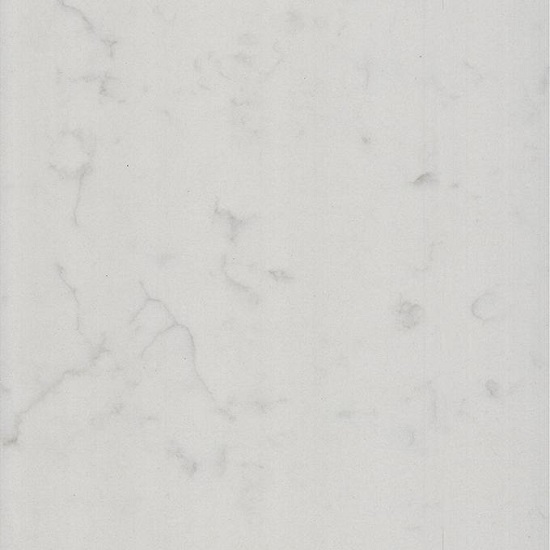

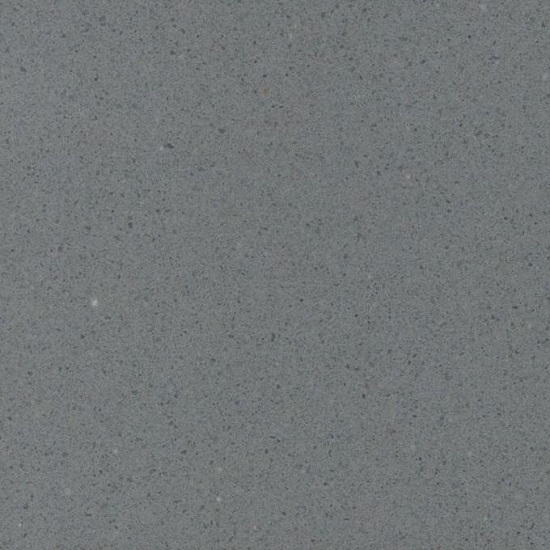

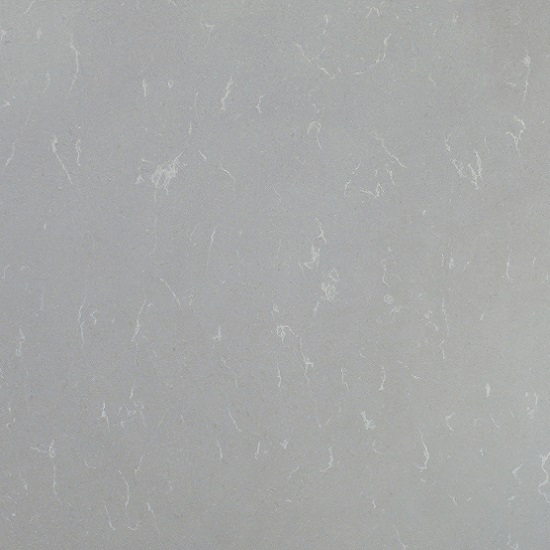

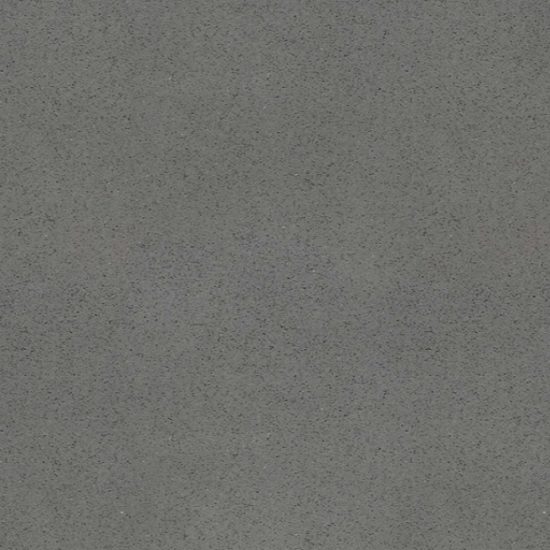

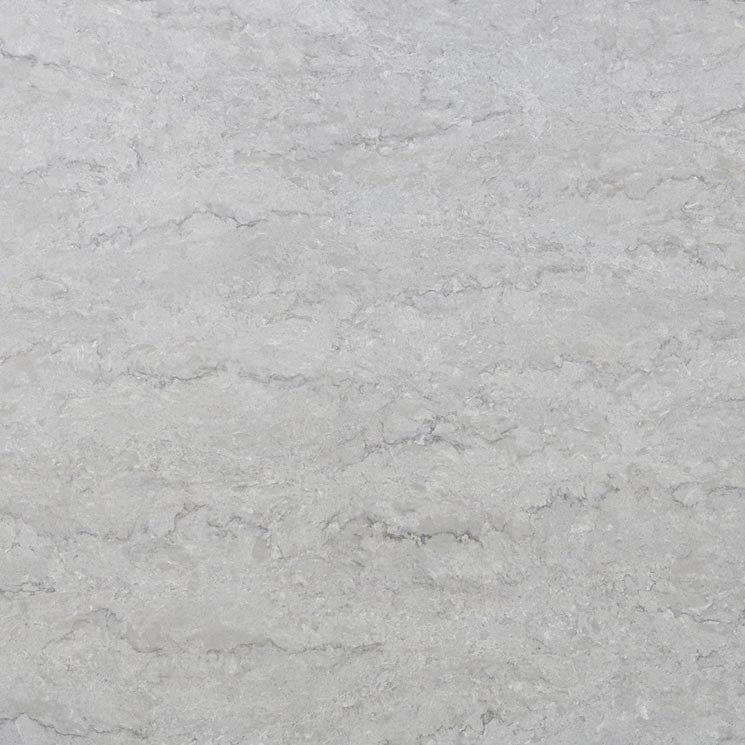

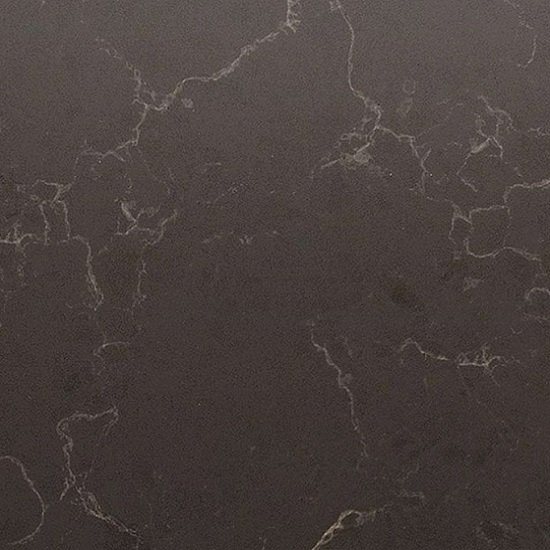

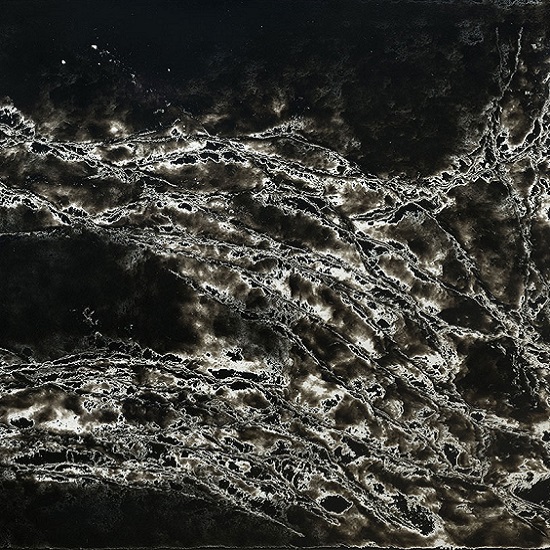

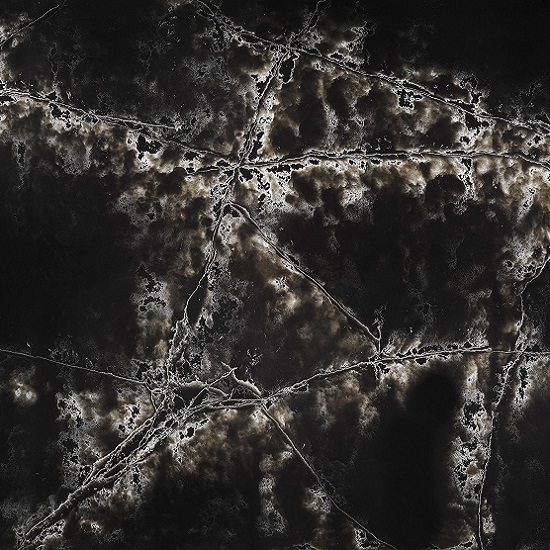

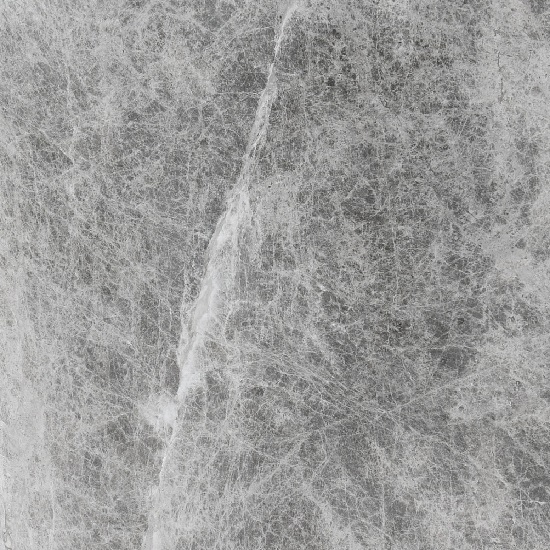

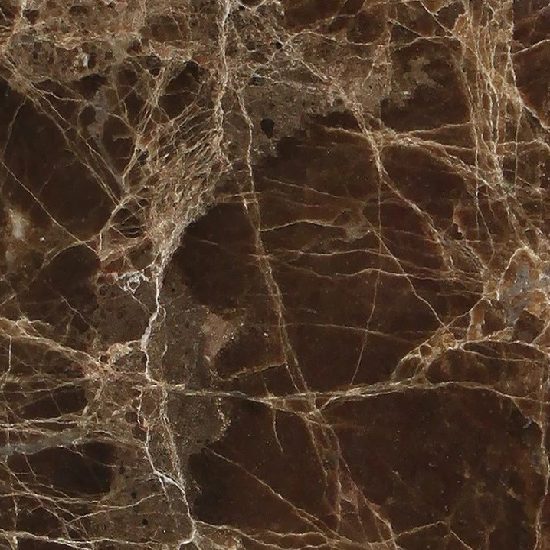

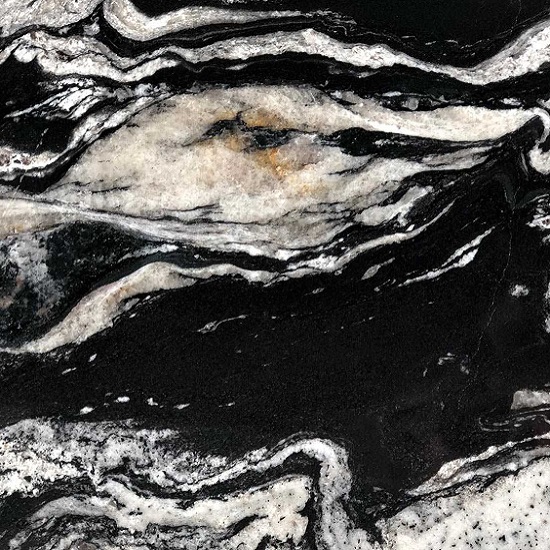

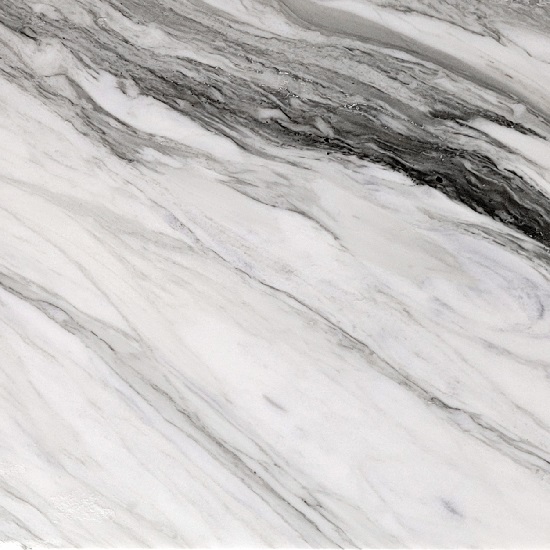

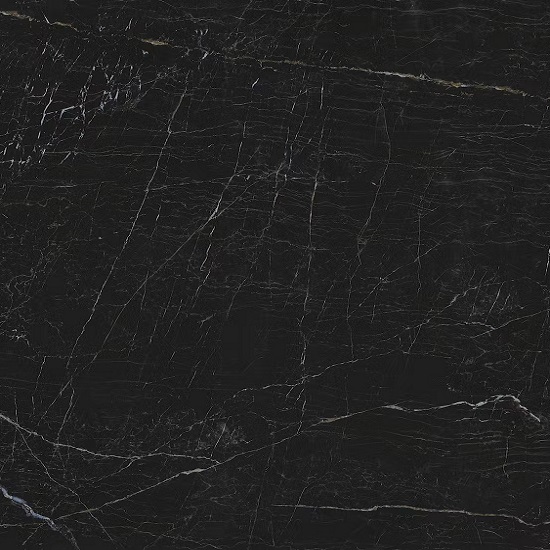

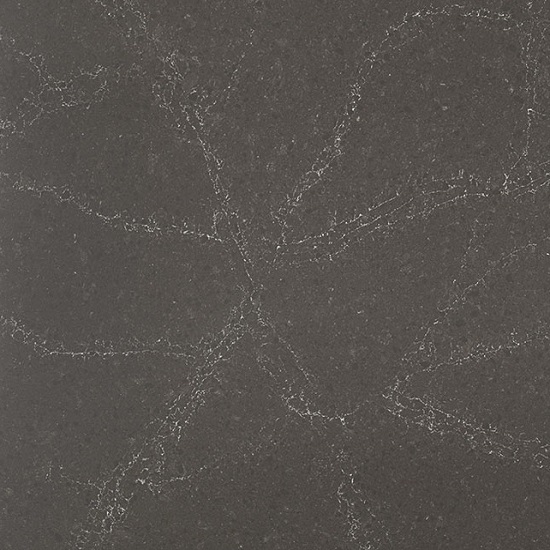

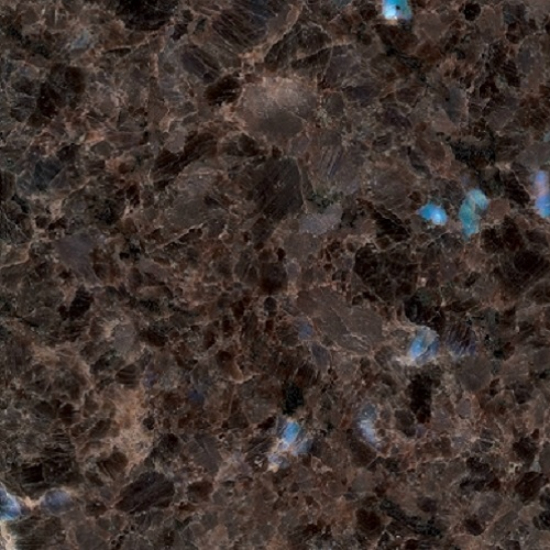

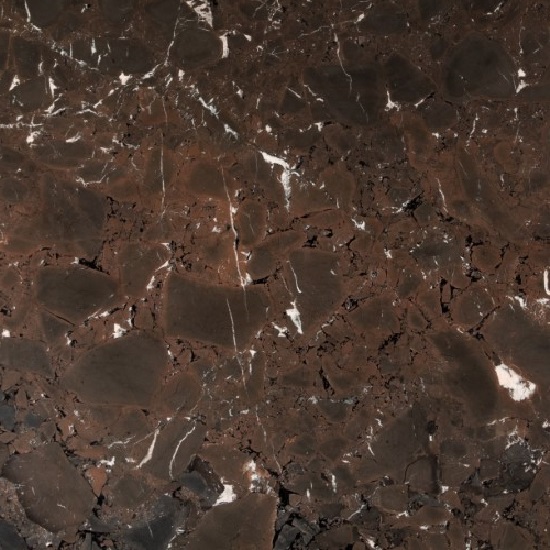

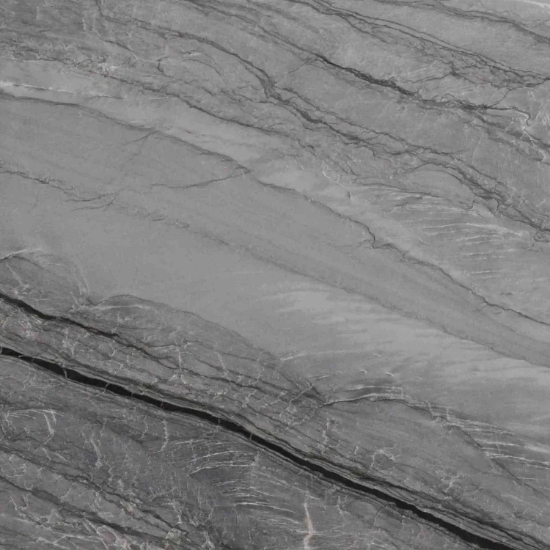

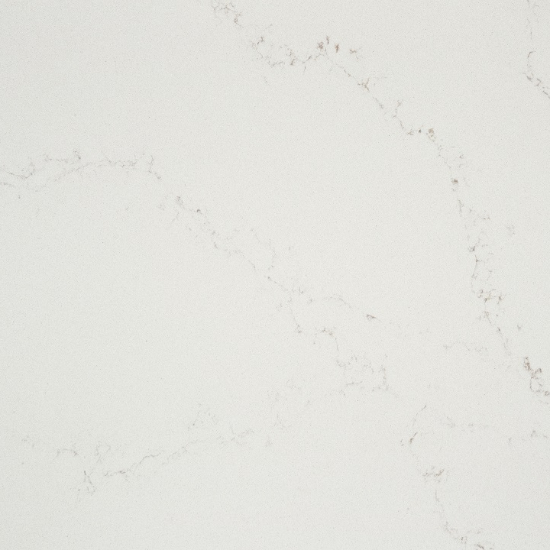

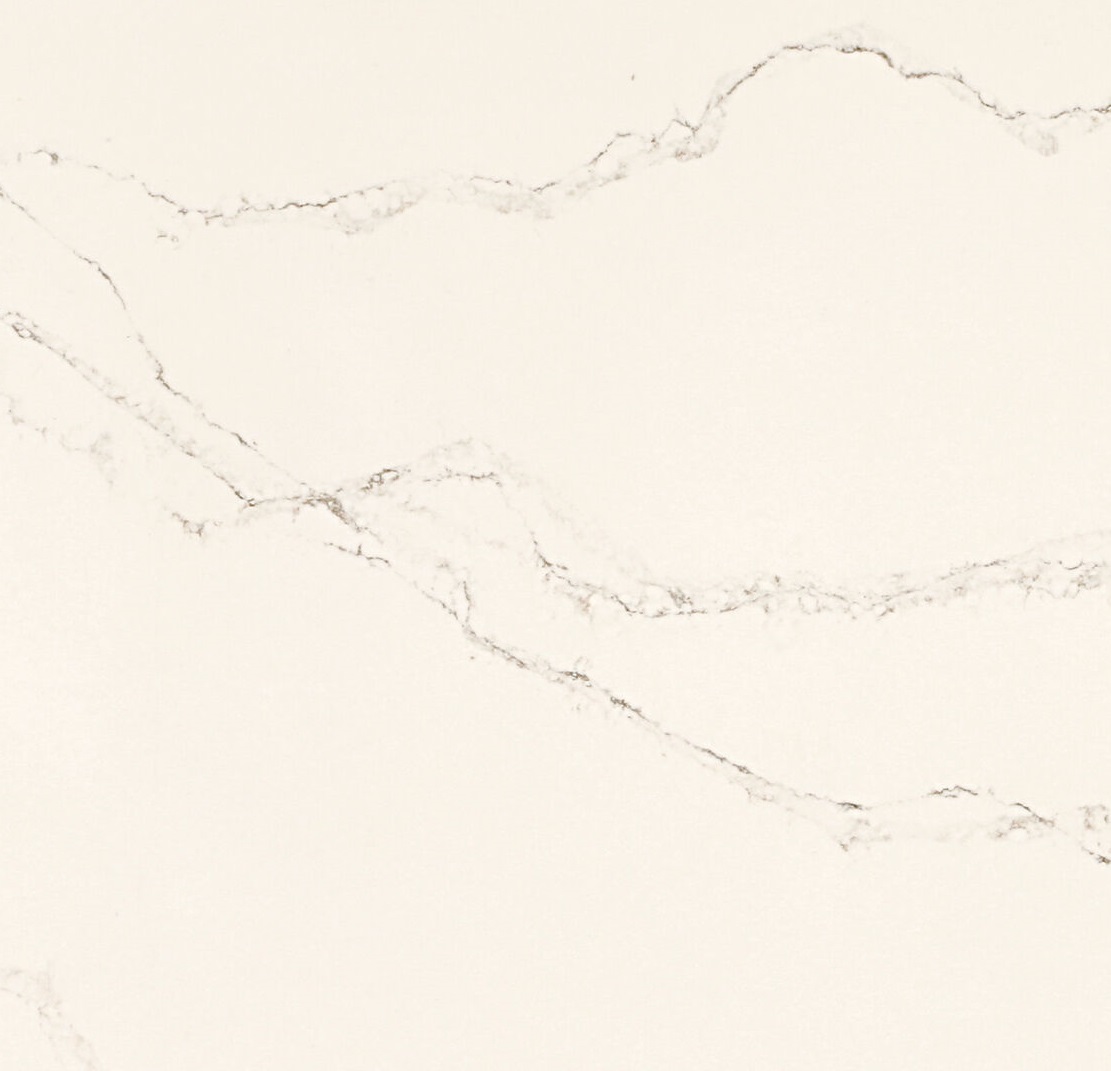

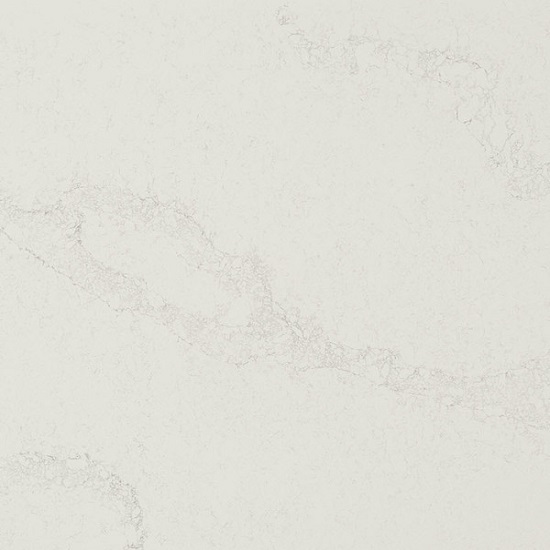

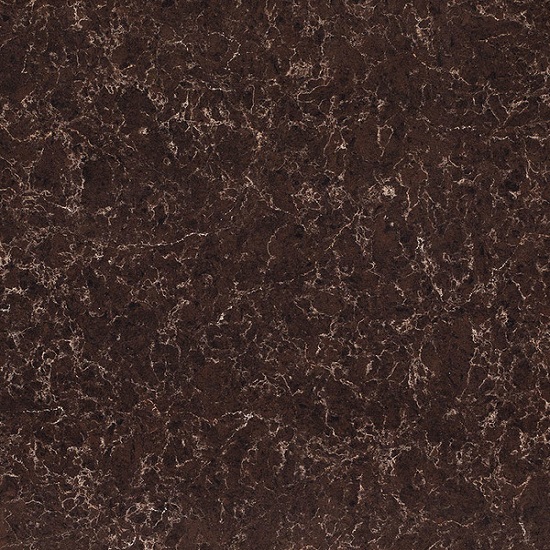

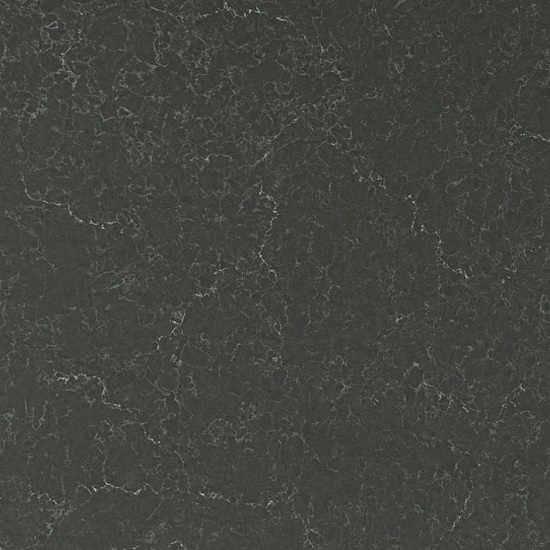

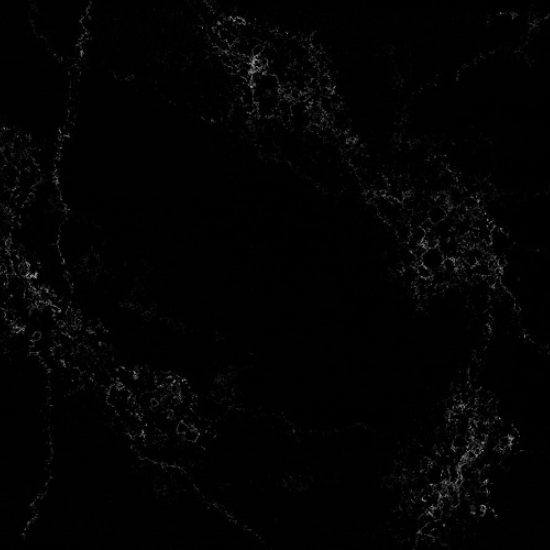

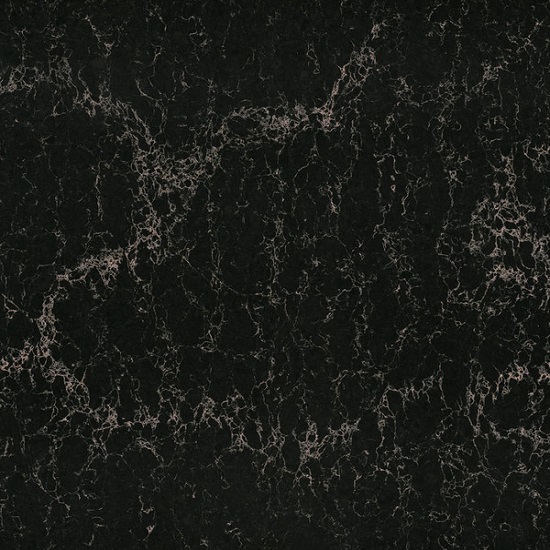

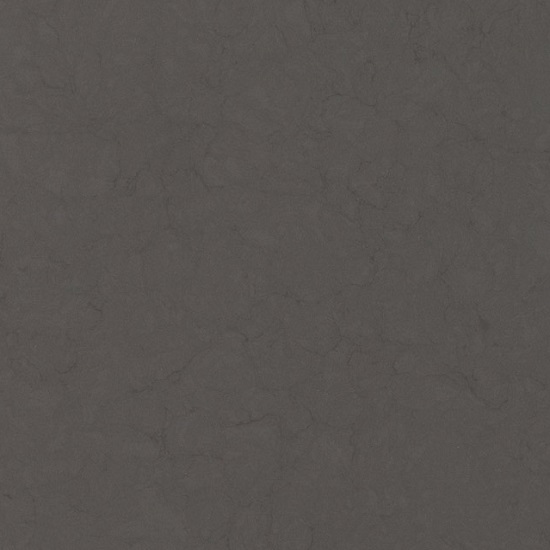

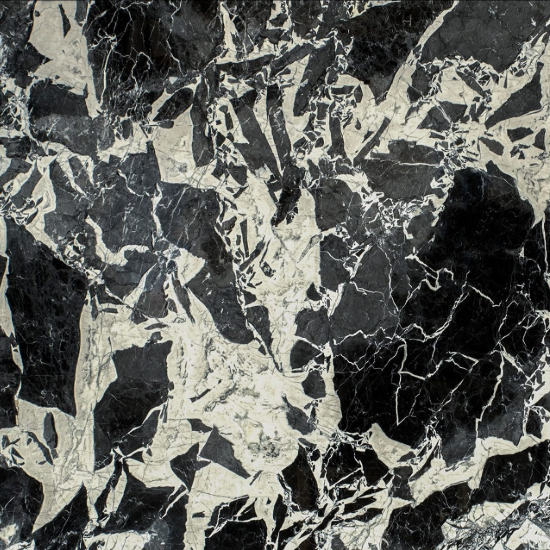

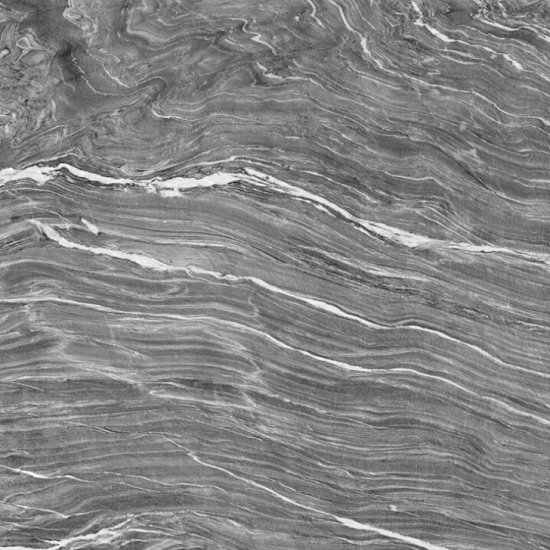

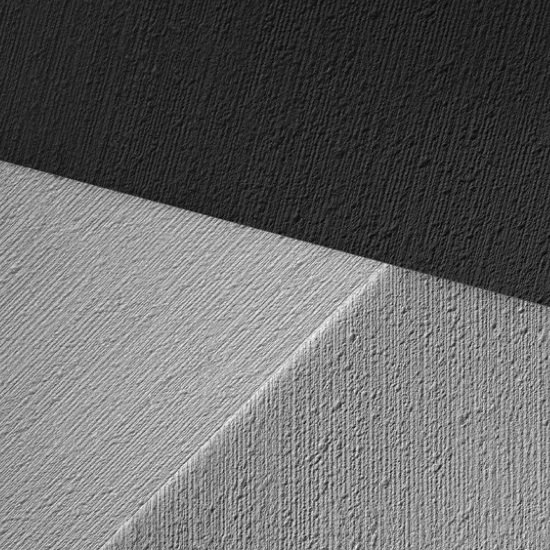

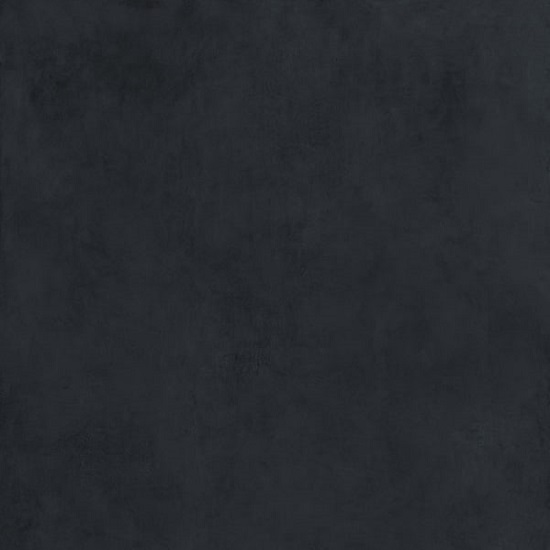

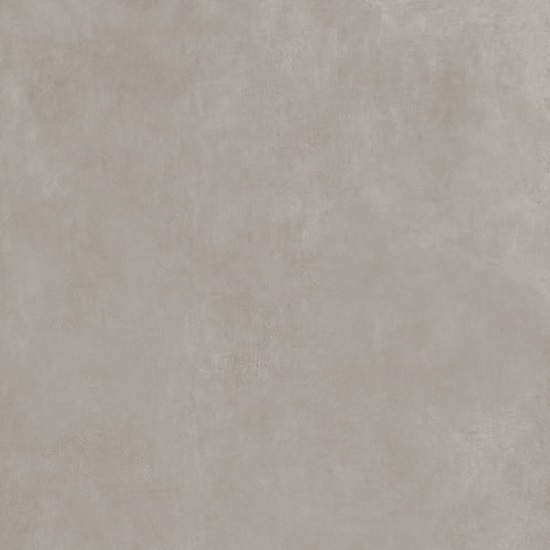

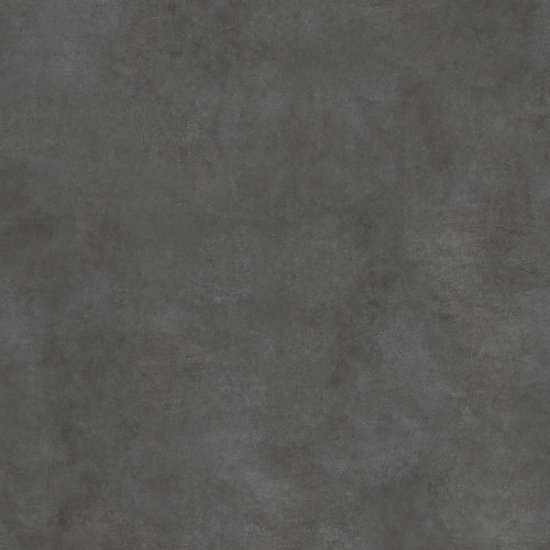

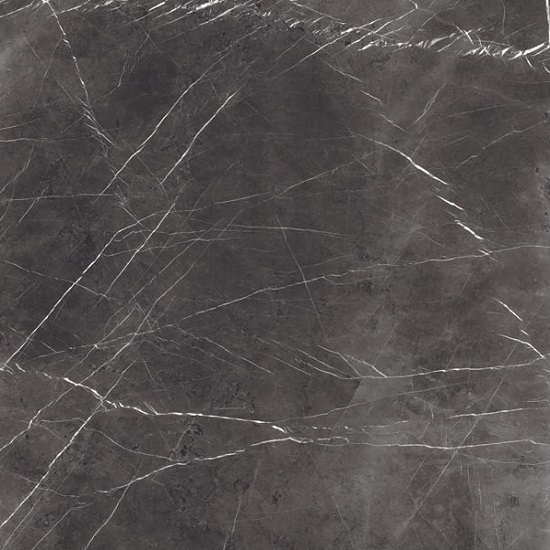

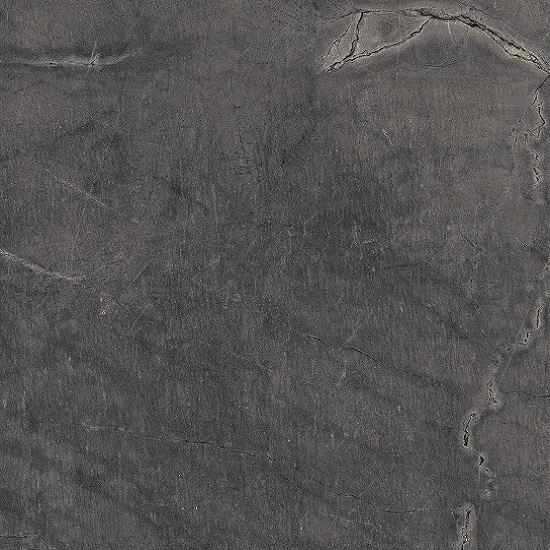

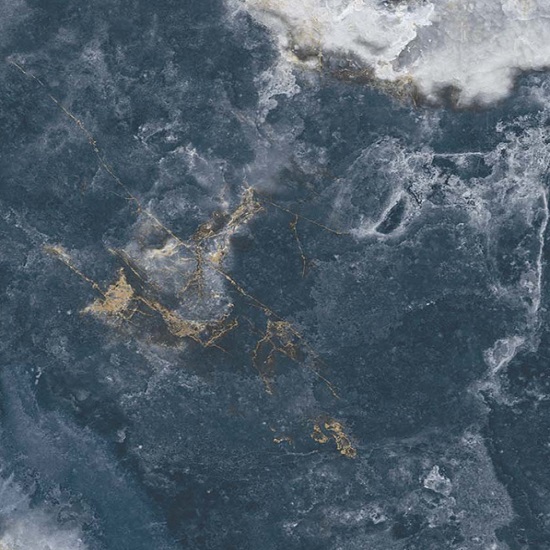

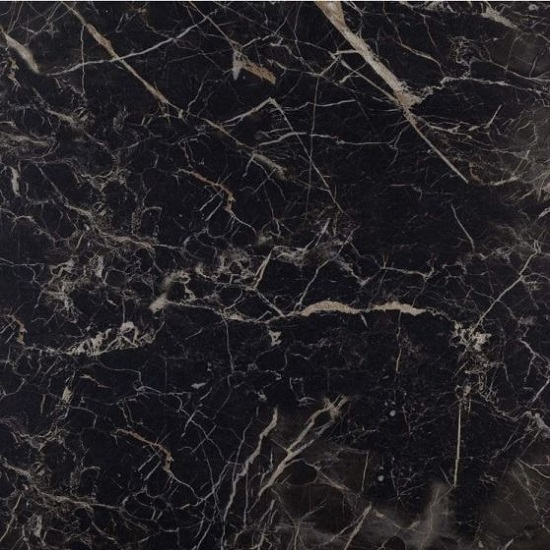

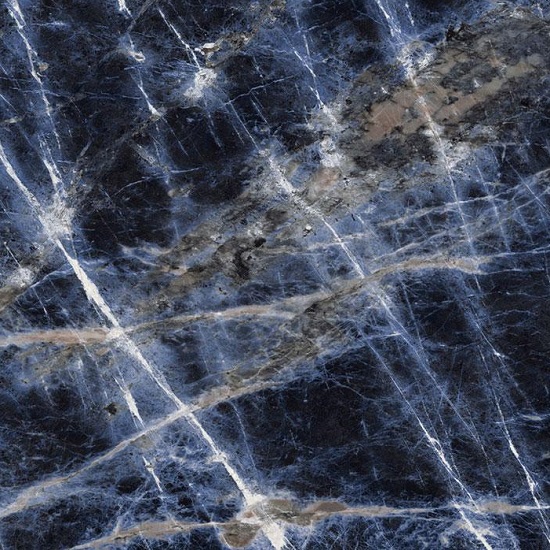

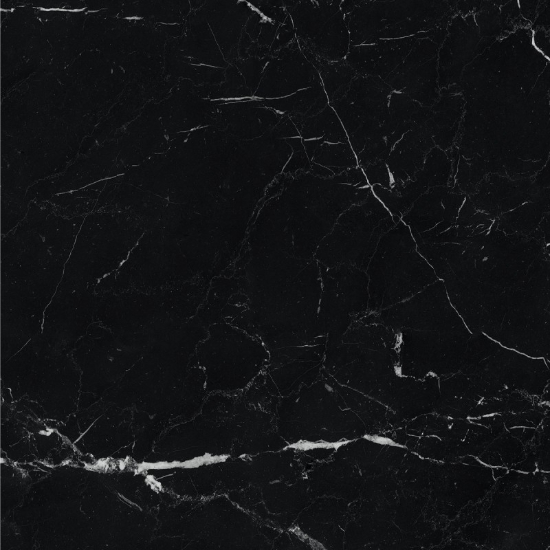

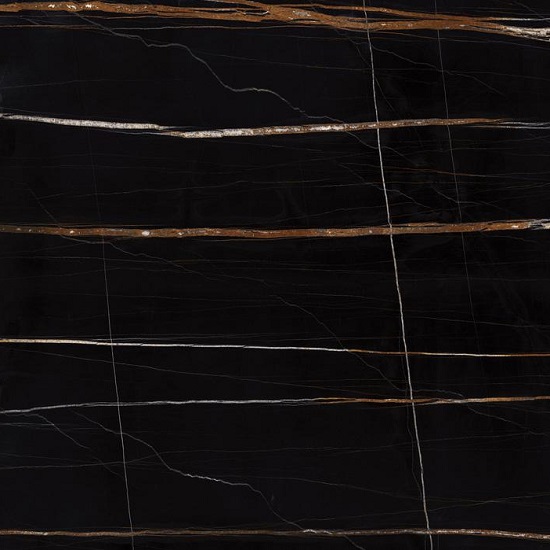

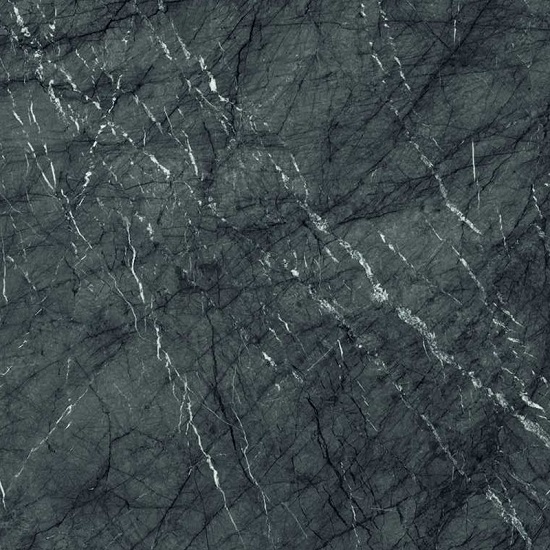

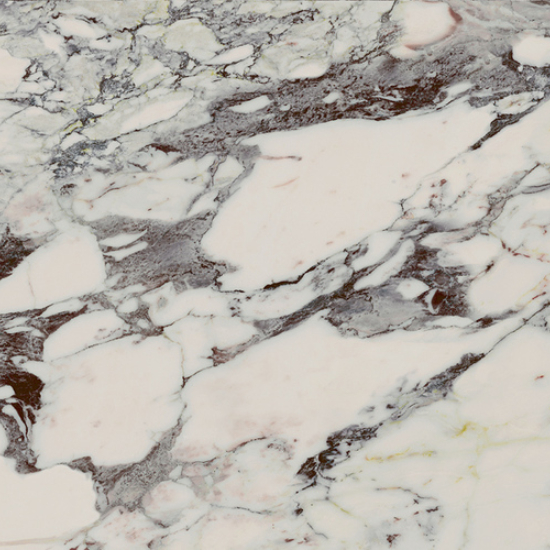

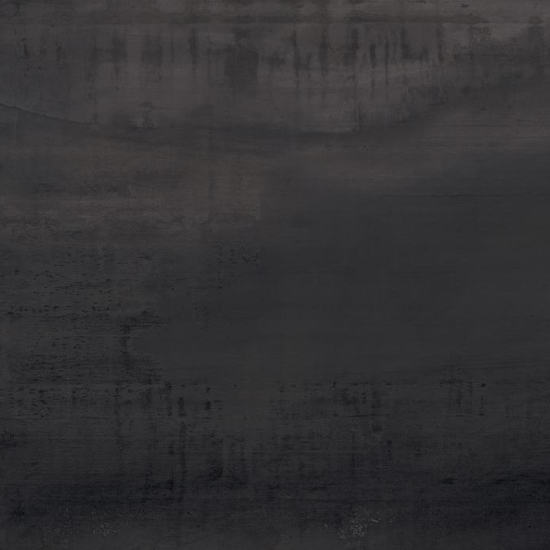

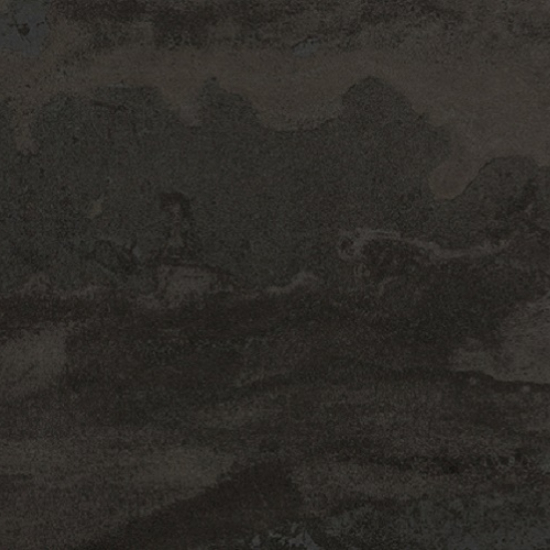

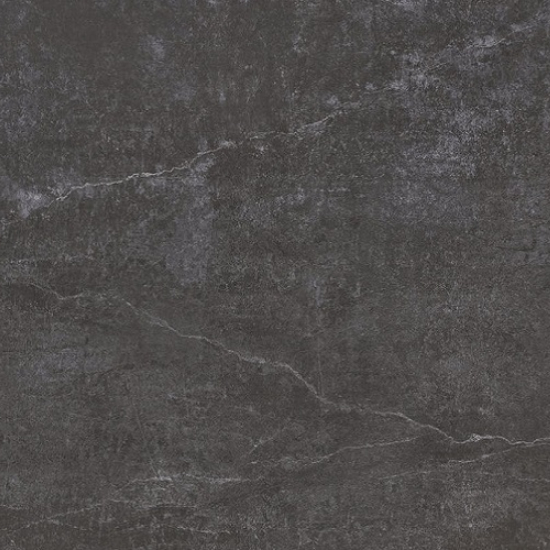

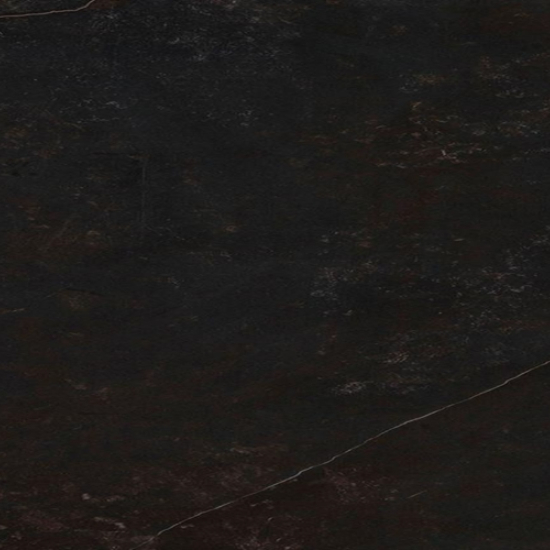

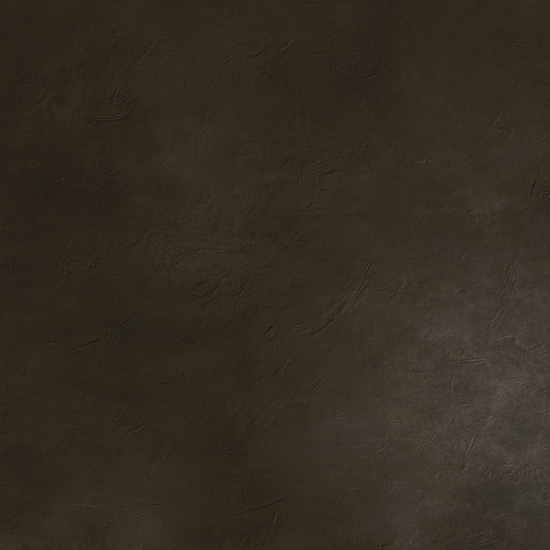

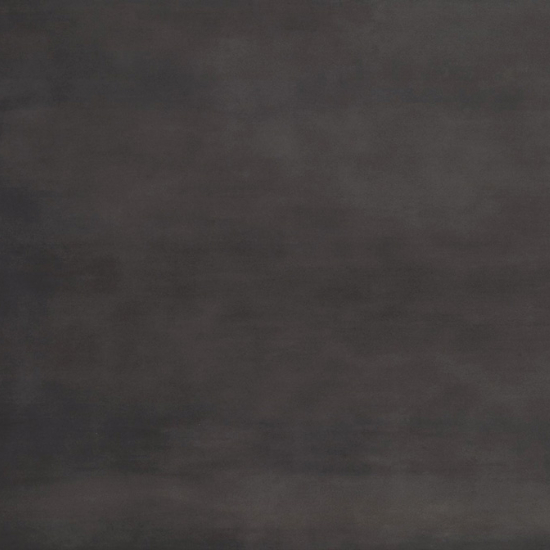

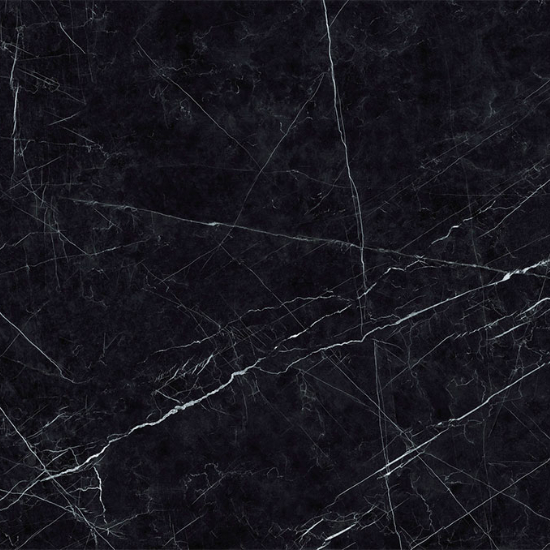

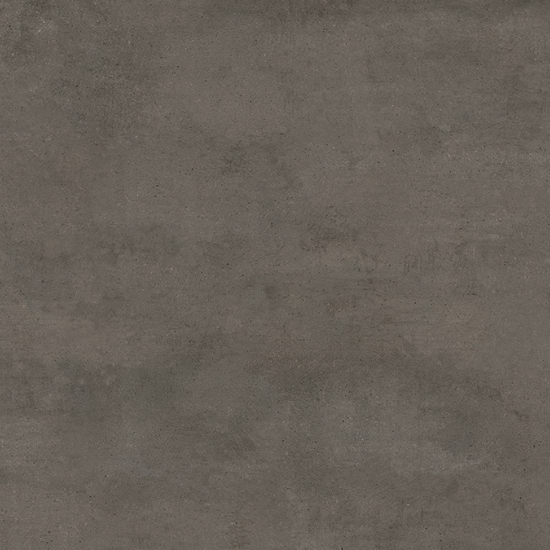

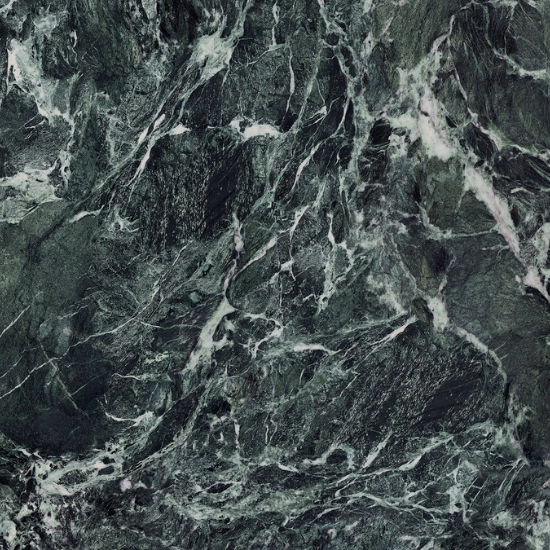

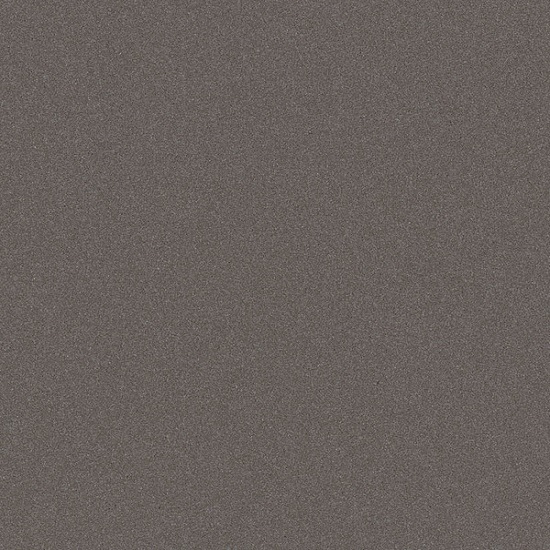

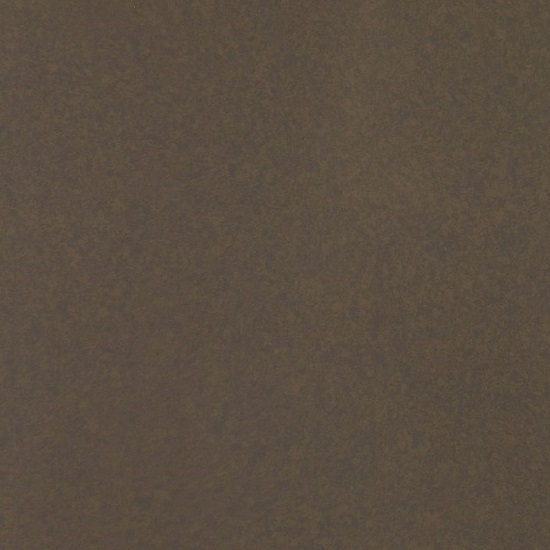

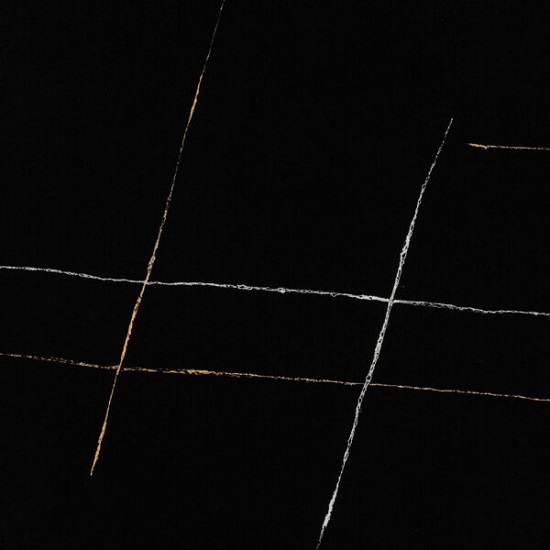

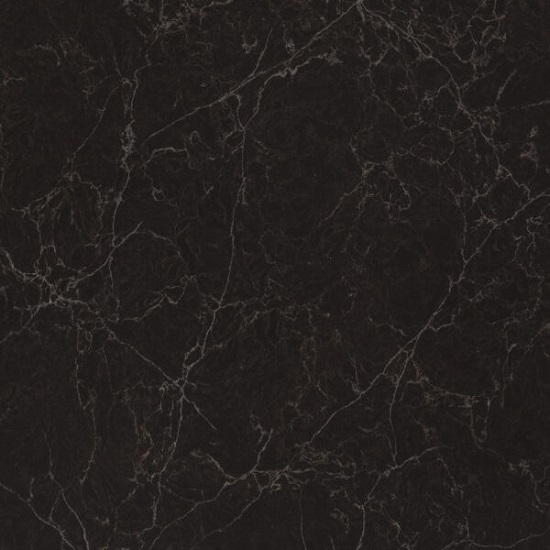

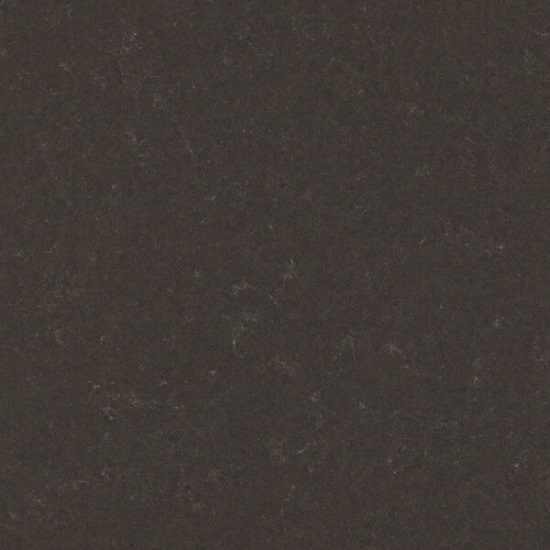

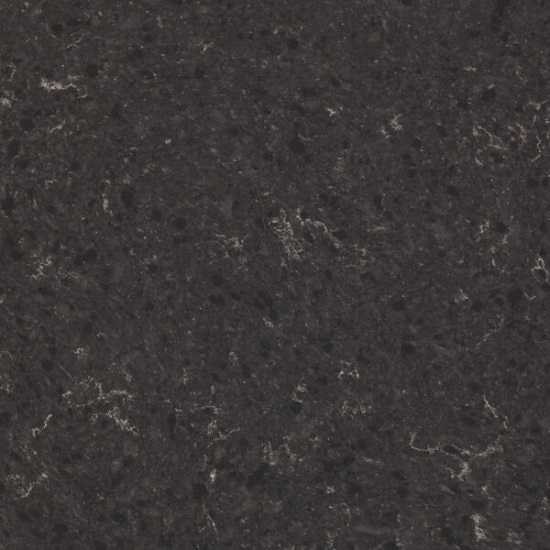

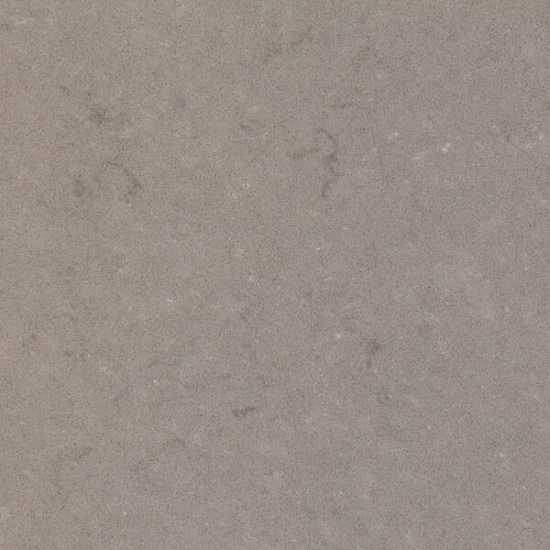

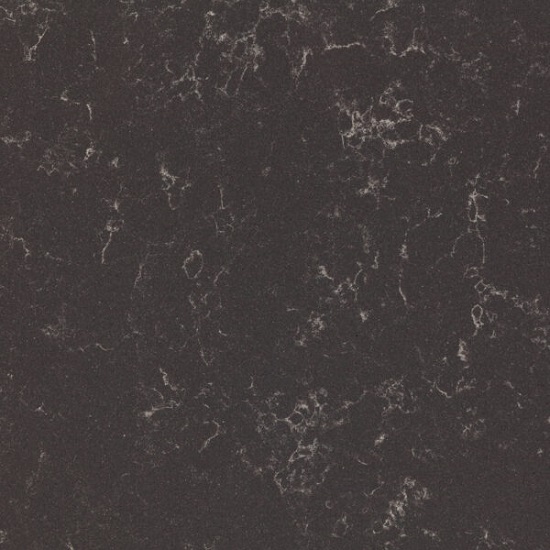

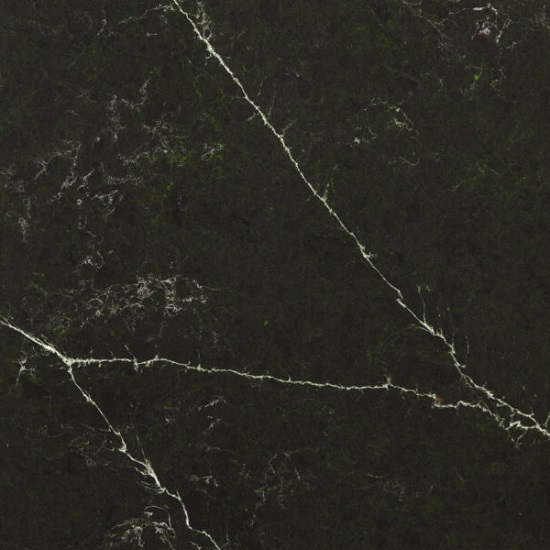

Download Brochure Download Maintenance GuidelinesMarazzi Lasa takes inspiration from an ancient Italian marble formed over 400 million years ago: marble: Bianco Lasa. Marazzi Lasa has a dark brown hue with dark intervals mixed in with pure white veining, demonstrating how amazing nature is in the development of natural marble.

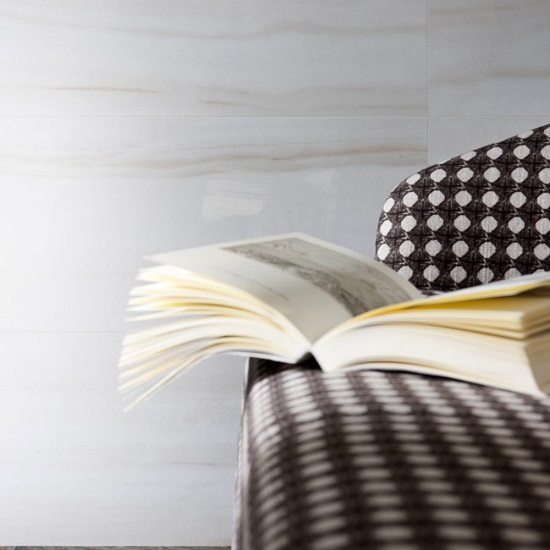

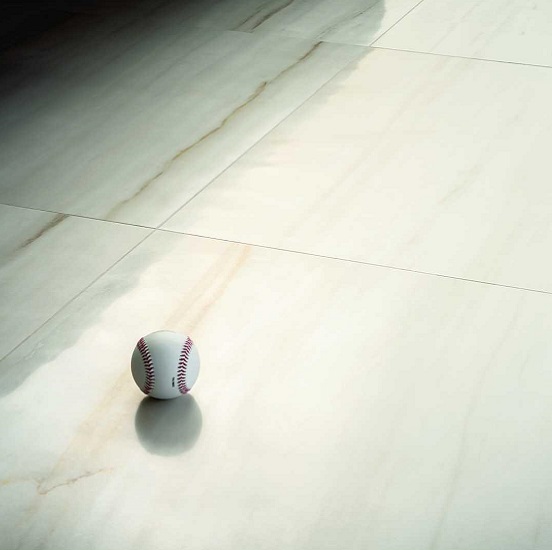

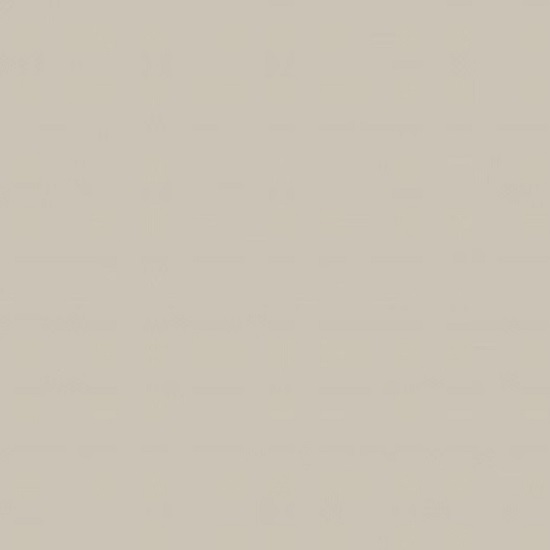

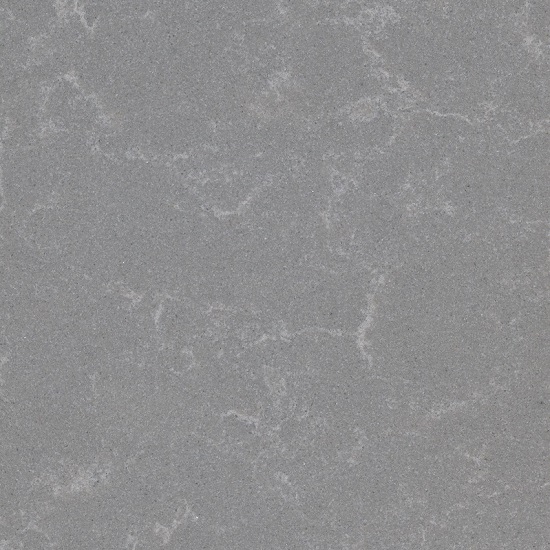

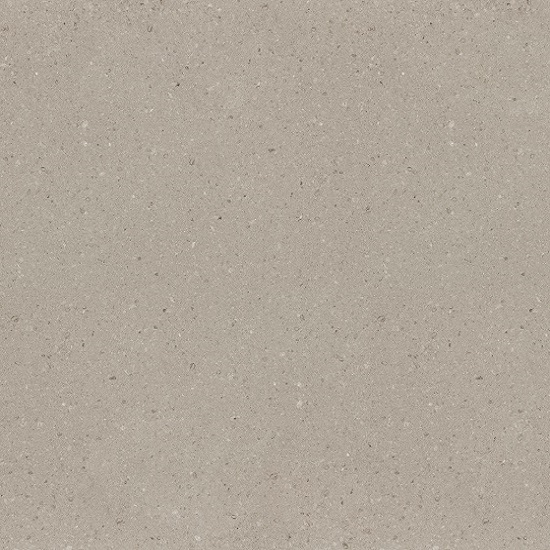

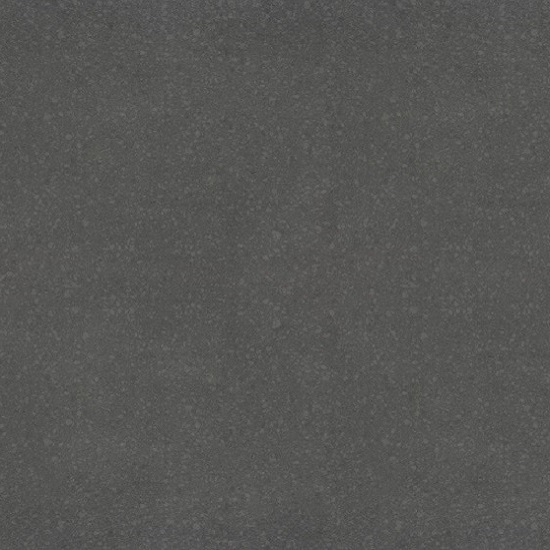

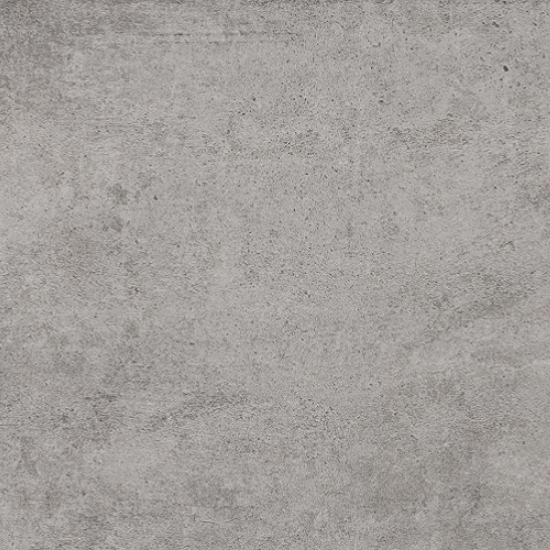

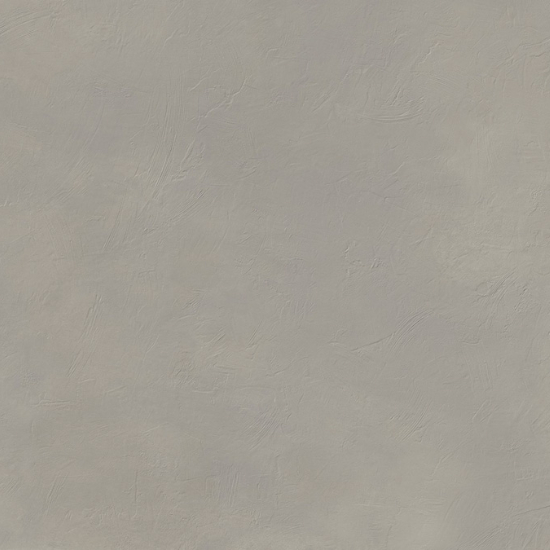

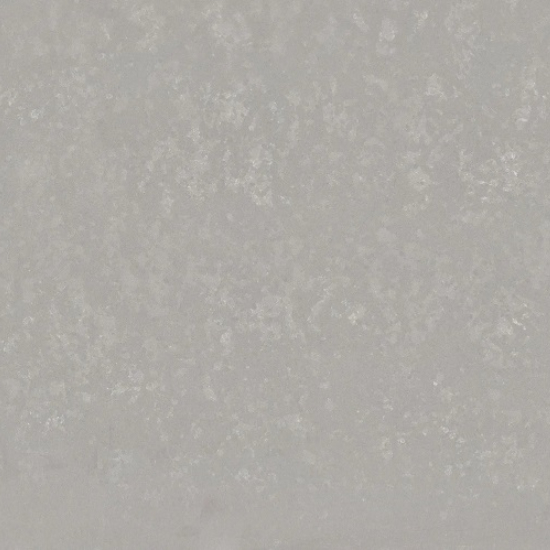

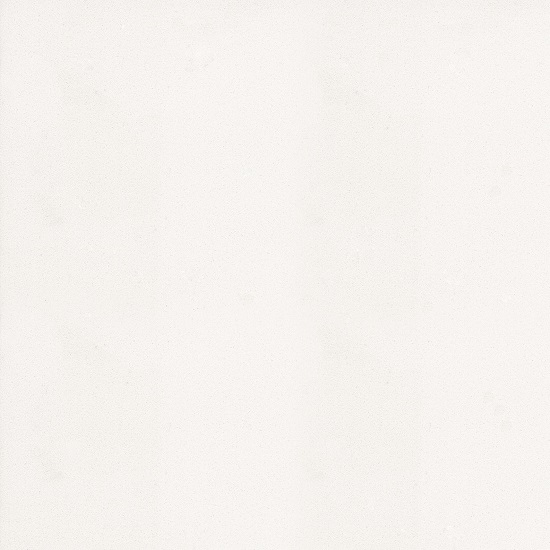

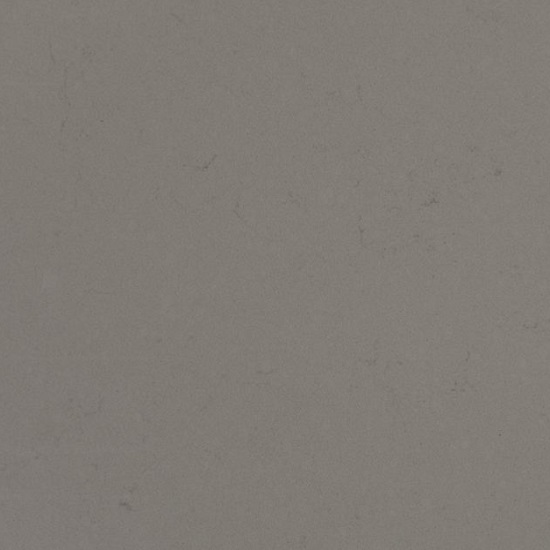

The Top surfaces by Marazzi allow you to create spaces with colour uniformity using an adaptable and long-lasting stone. In addition, the zero surface porosity provides the highest hygiene and sanitation requirements.

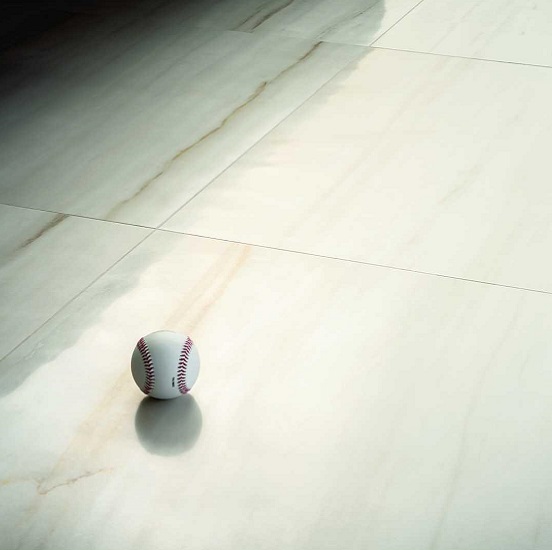

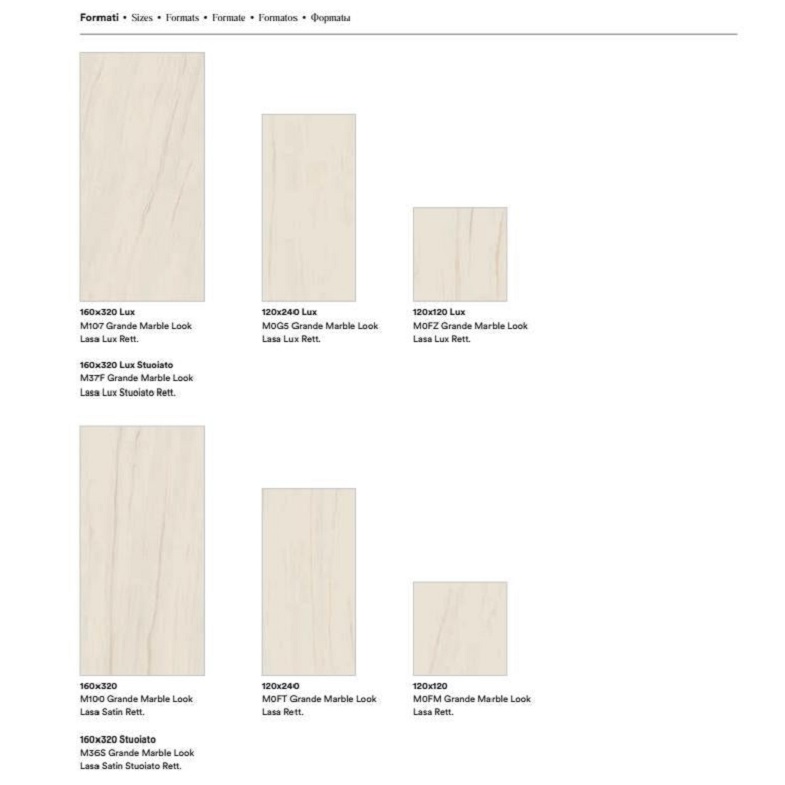

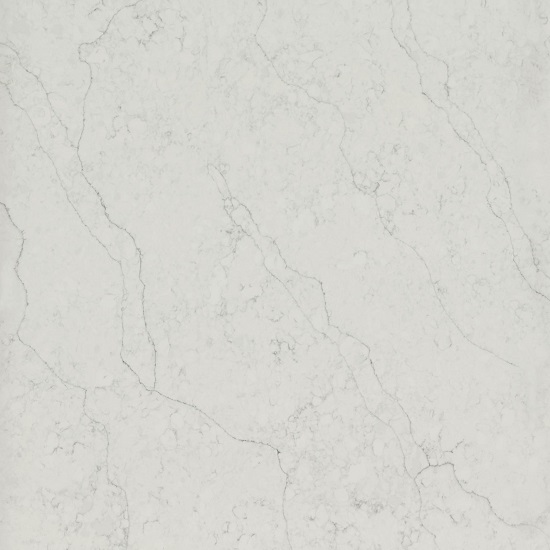

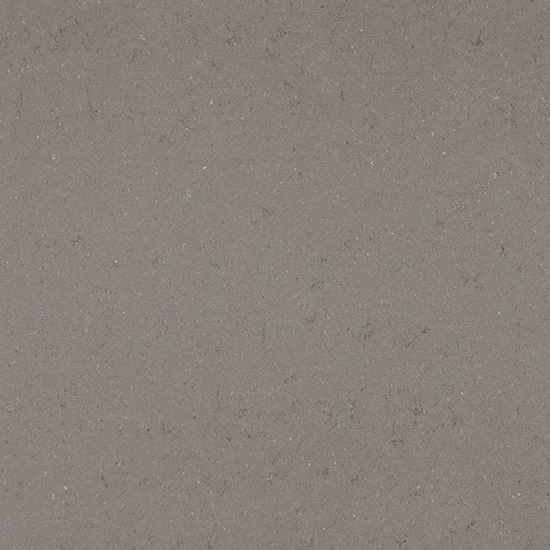

The 324 x 162 cm slabs bring superior performance attributes to a new world of interior and landscape design possibilities. You can choose this sintered porcelain worktop with thicknesses of 6 mm and 12 mm, a highly polished finish known as ‘LUX’, and a beautifully Semi-Matte feel known as ‘Satin finish’.

Spillages of Wine, Coffee, and Tea Cannot Affect Marazzi Porcelain.

Unlike natural materials such as limestone, which, etches, when exposed to acid from fruits and juices, Marazzi Lasa is 100 per cent immune to any liquids you use in the kitchen daily. So you can chop, cut and squeeze any fruits without worrying about damaging this versatile decoration material.

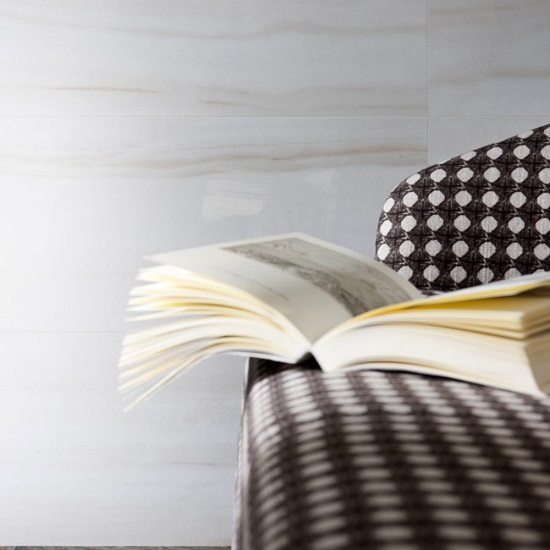

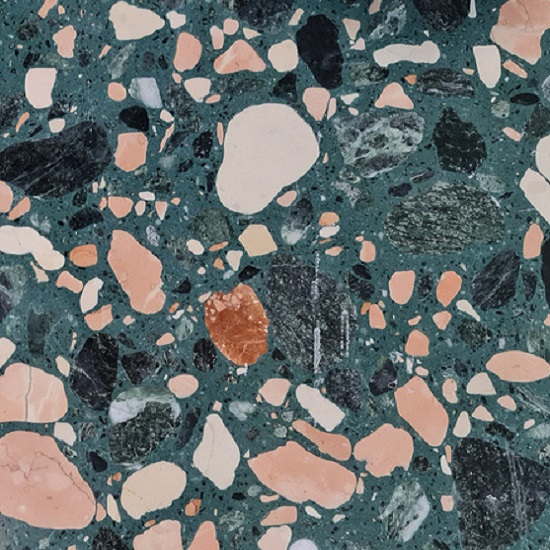

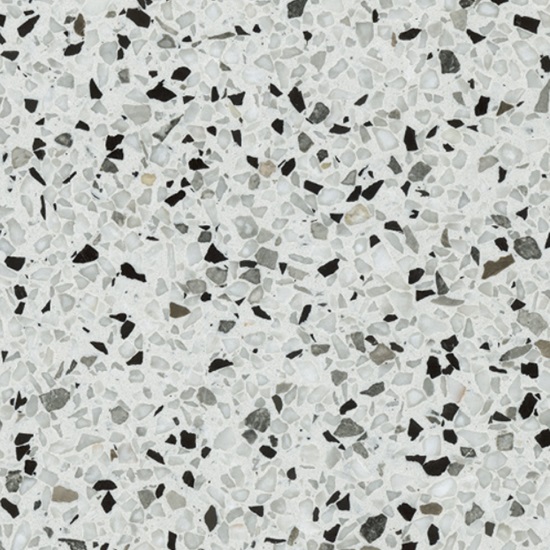

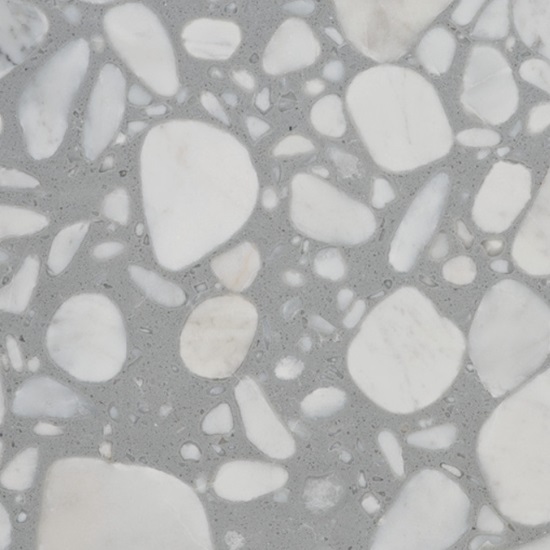

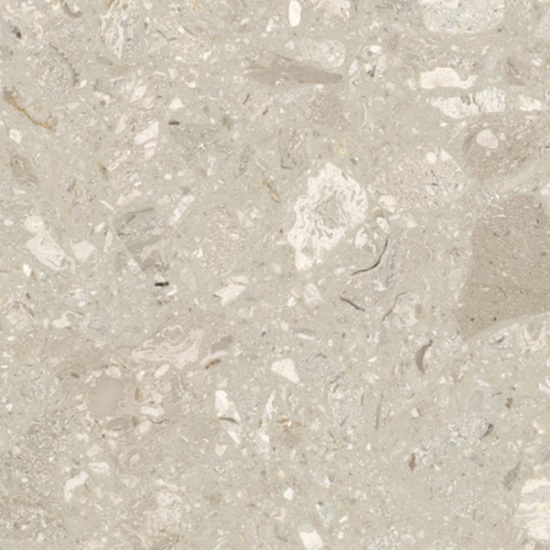

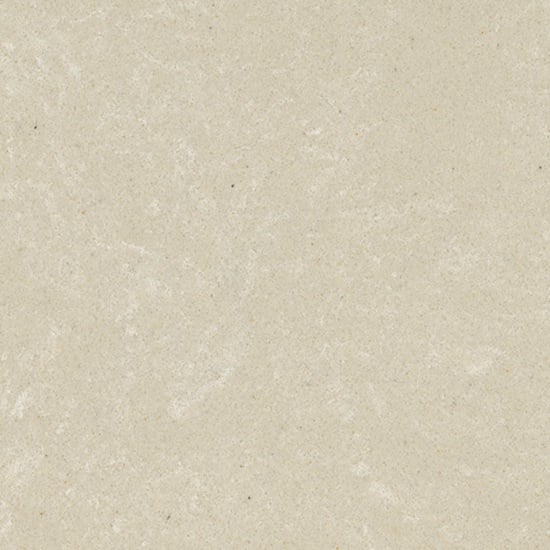

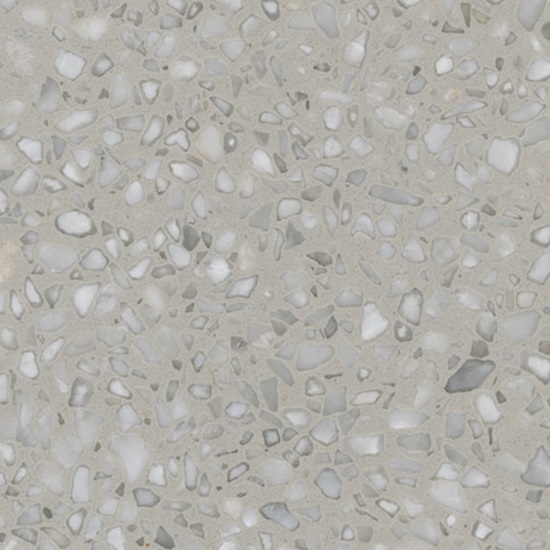

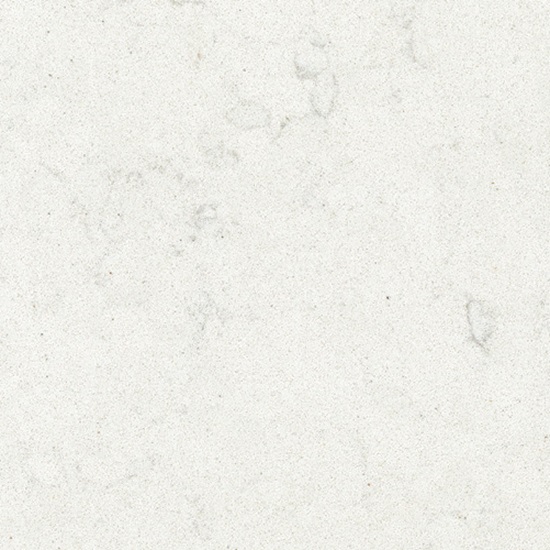

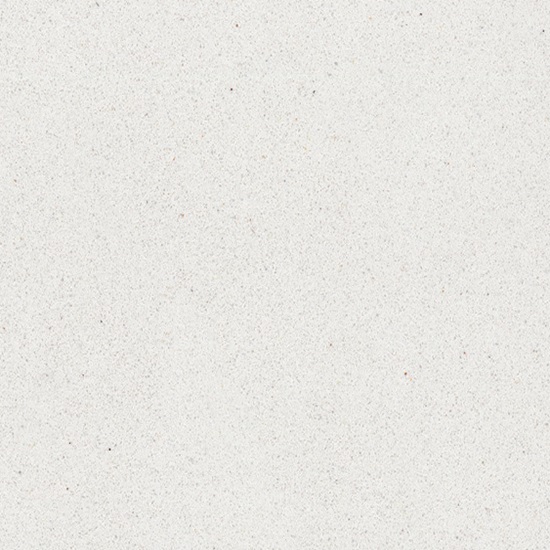

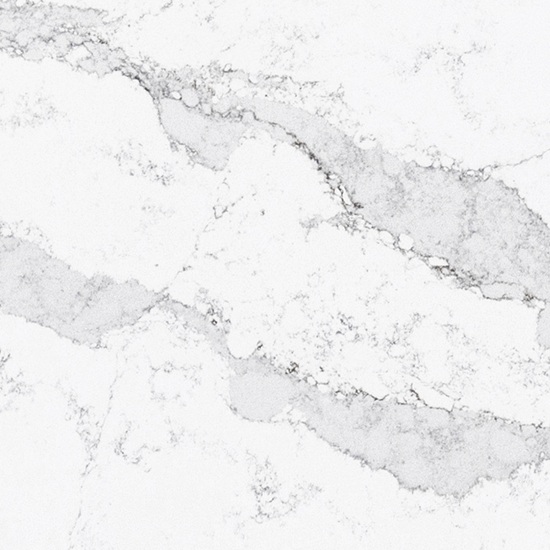

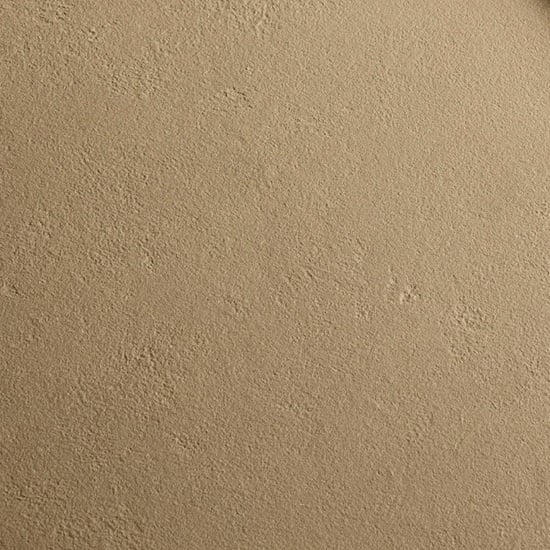

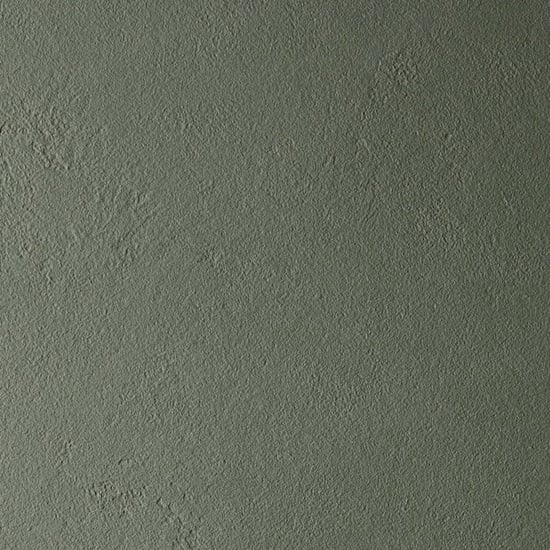

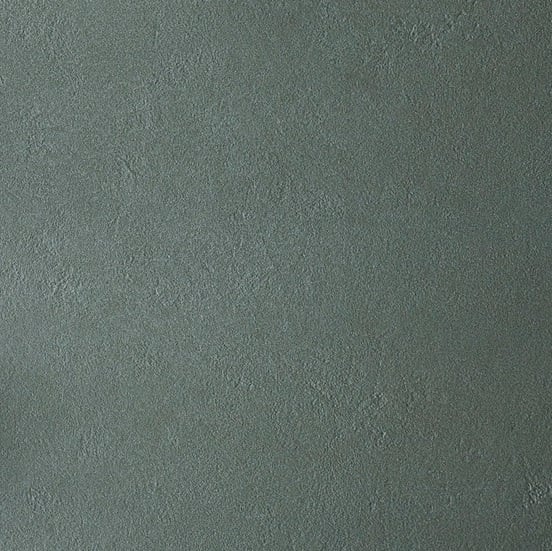

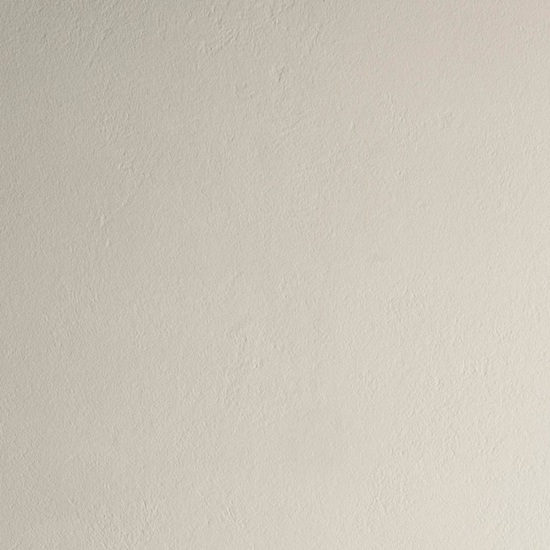

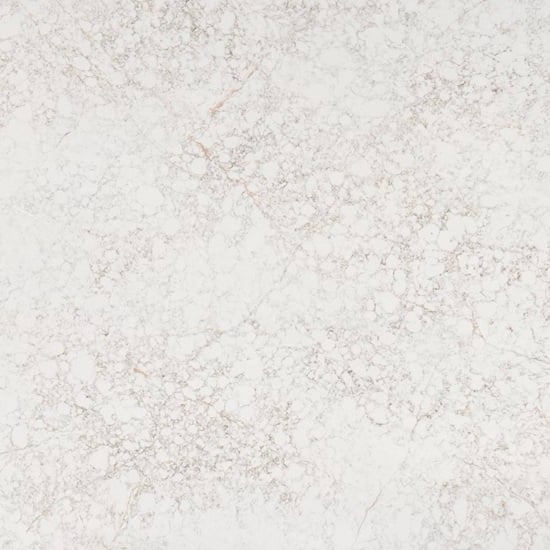

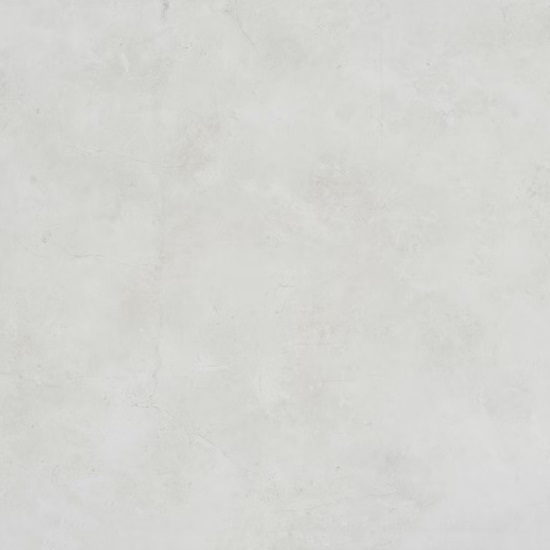

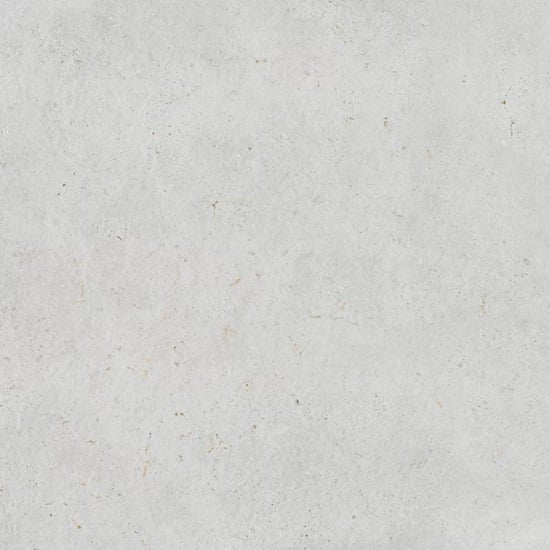

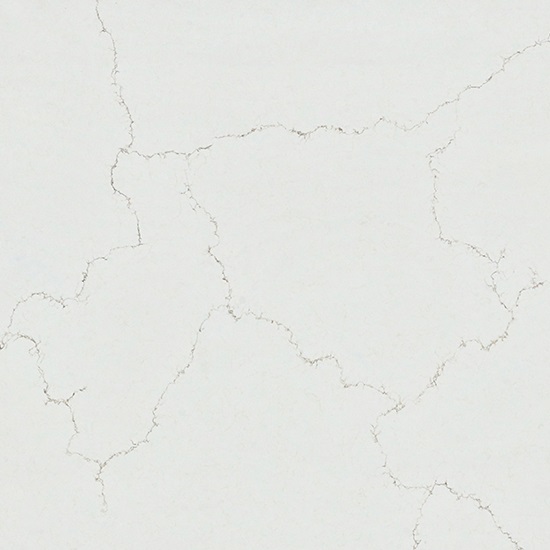

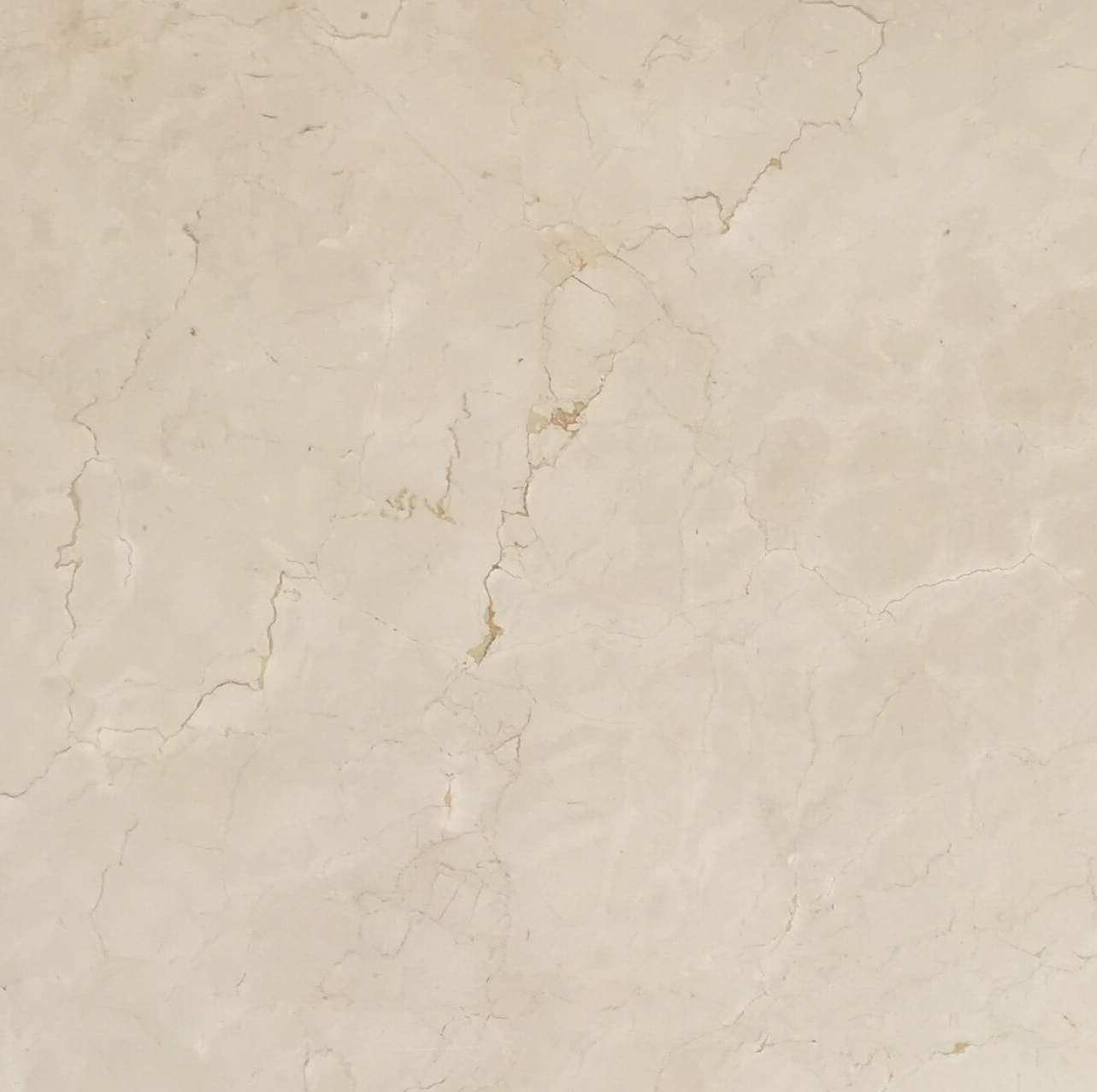

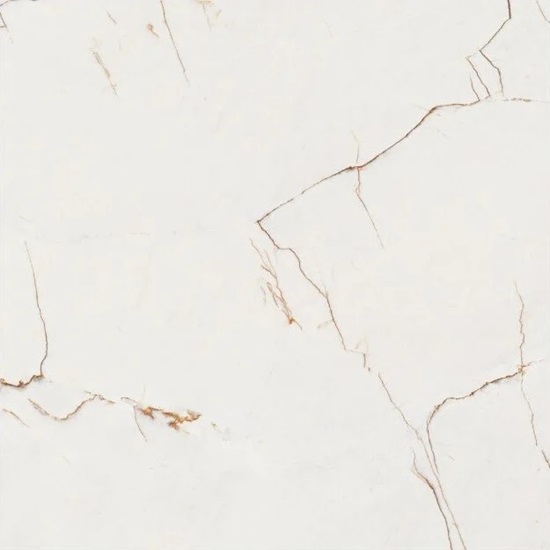

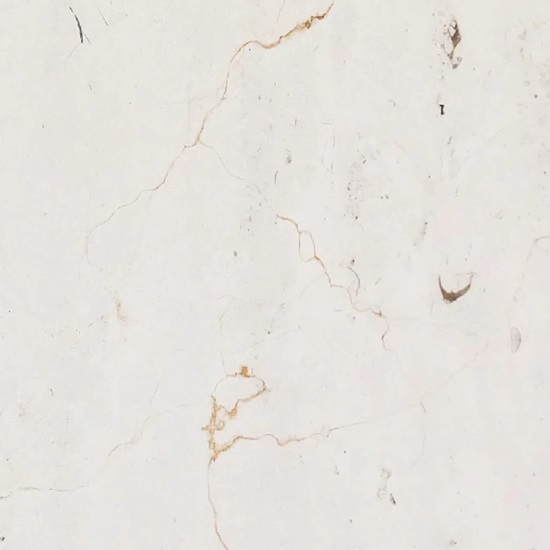

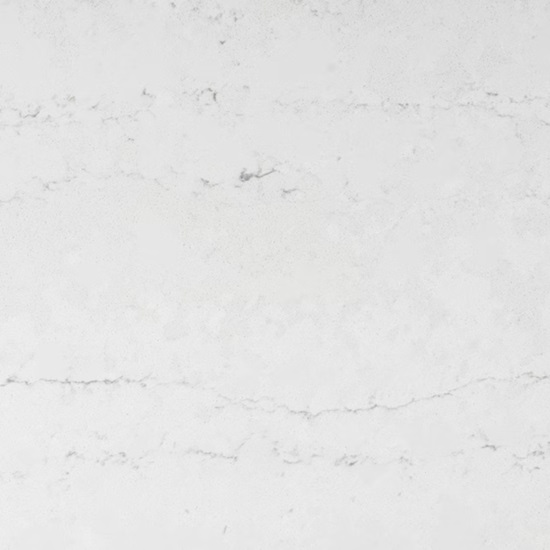

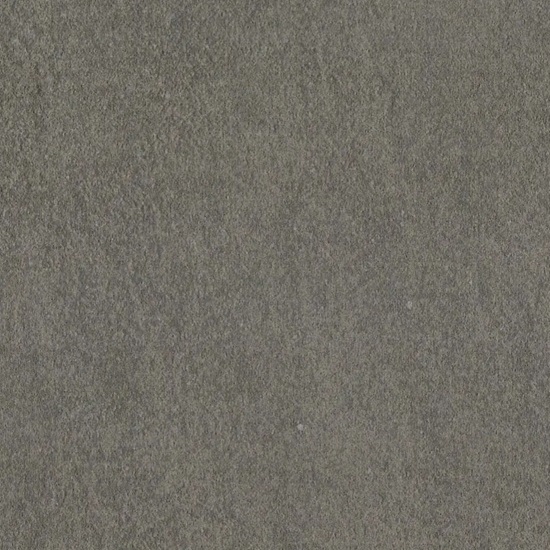

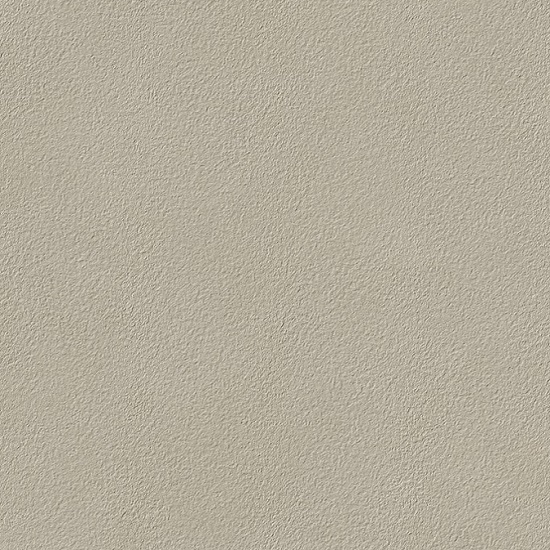

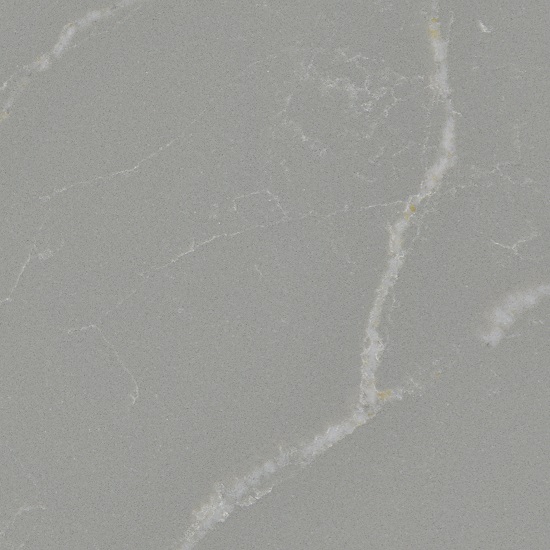

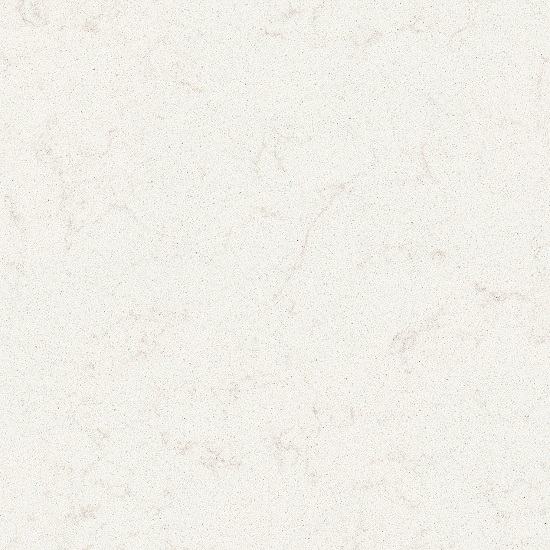

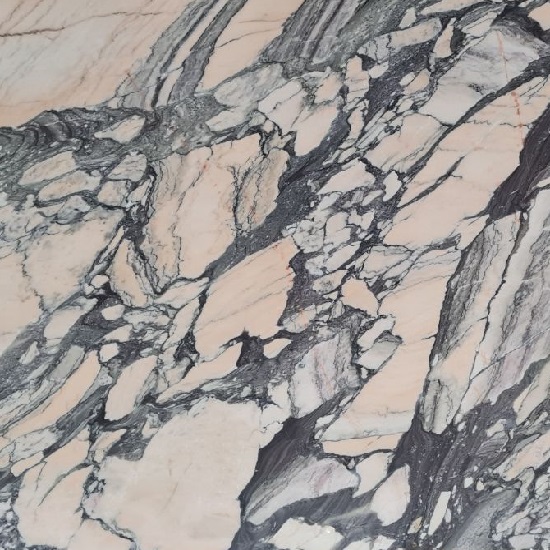

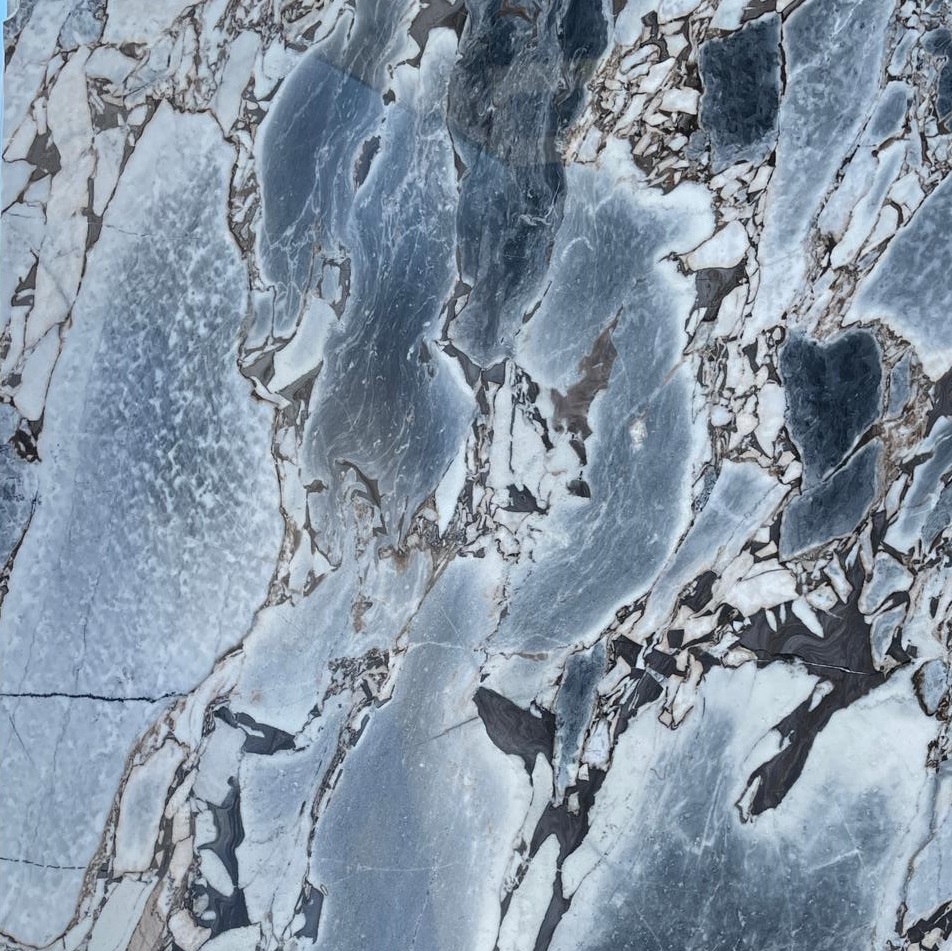

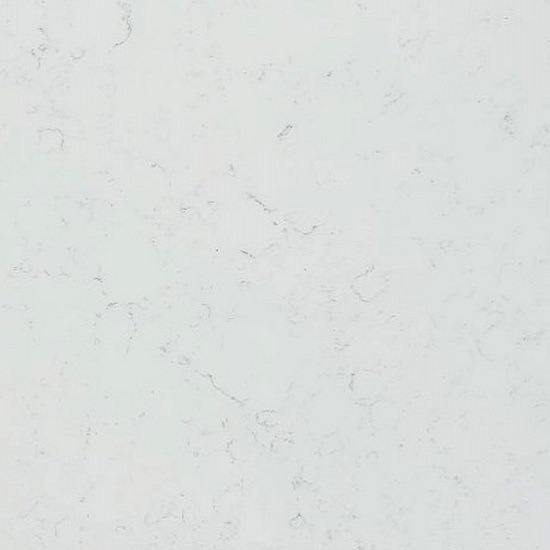

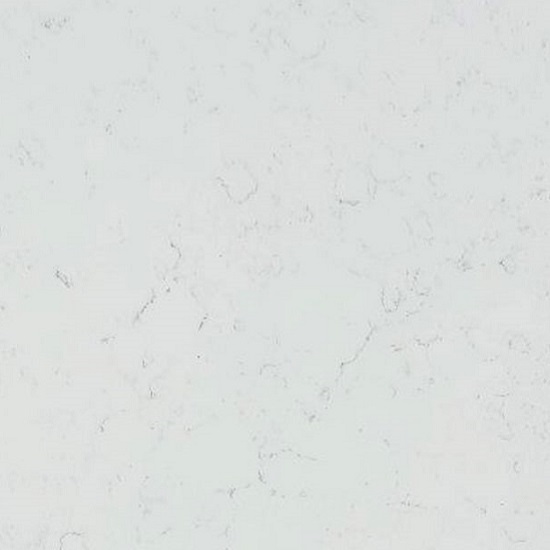

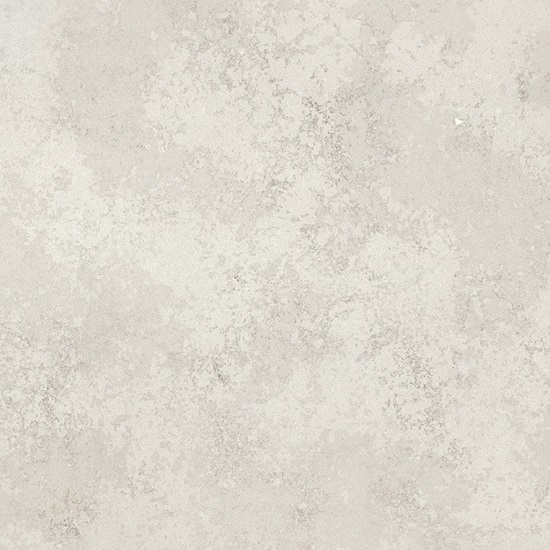

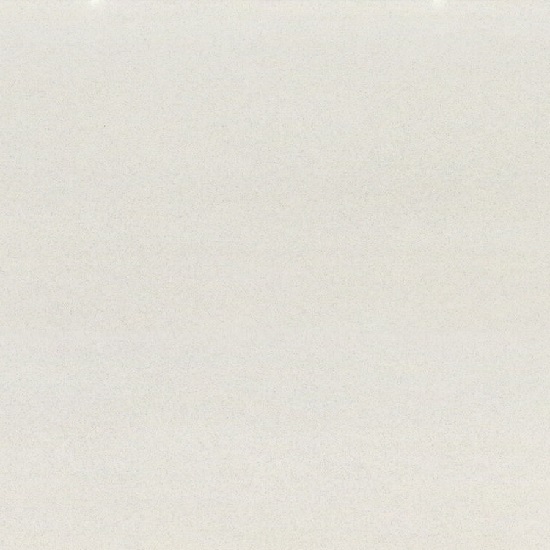

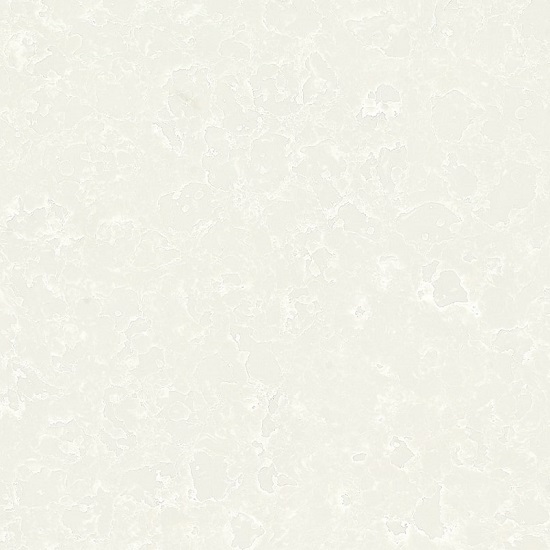

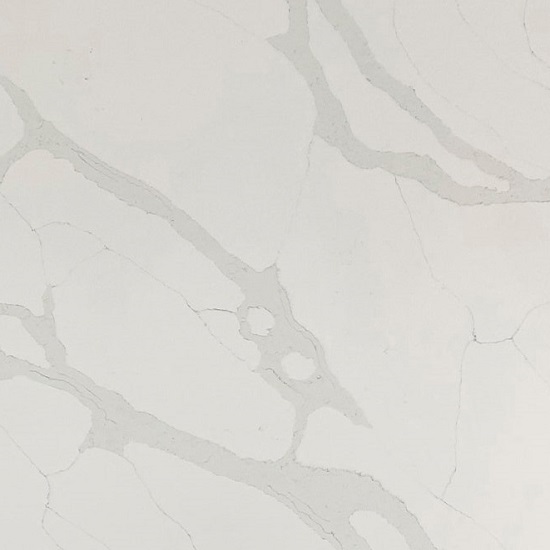

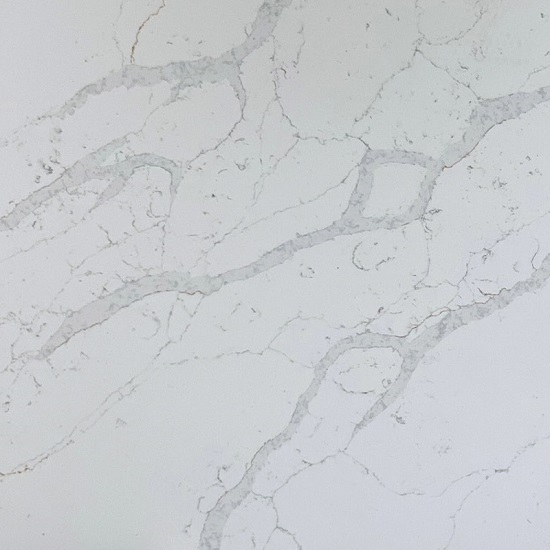

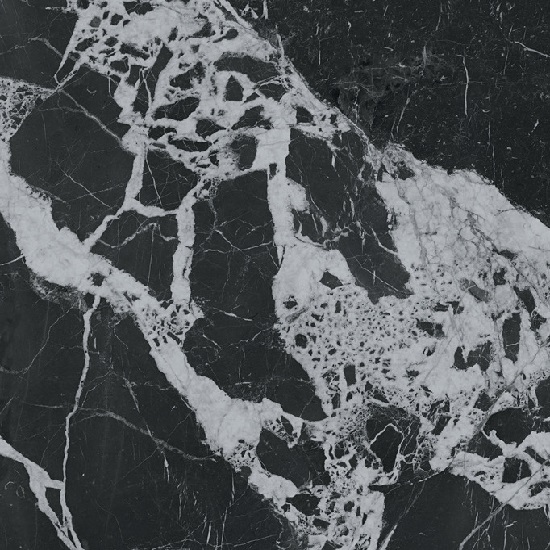

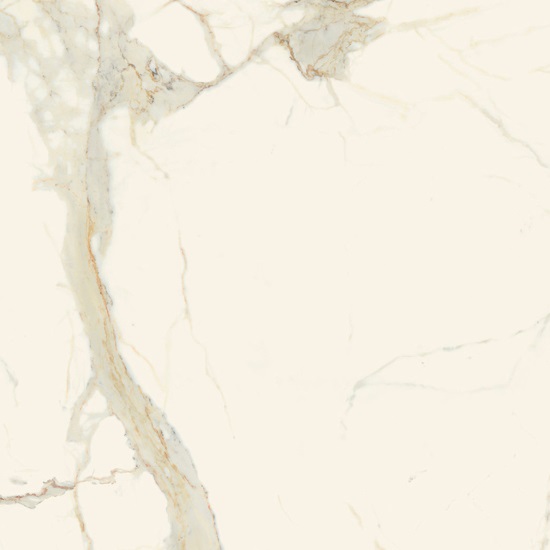

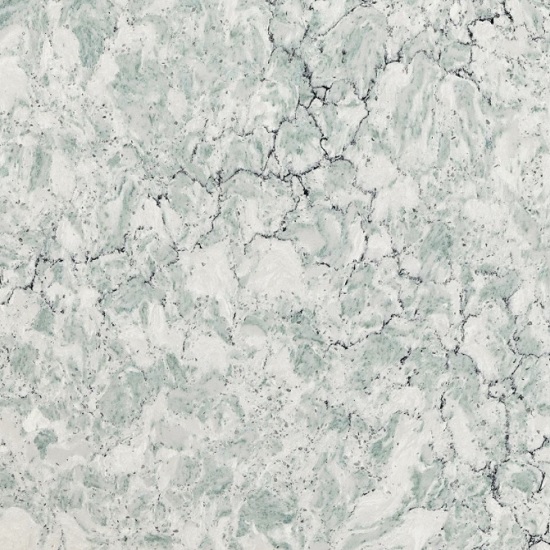

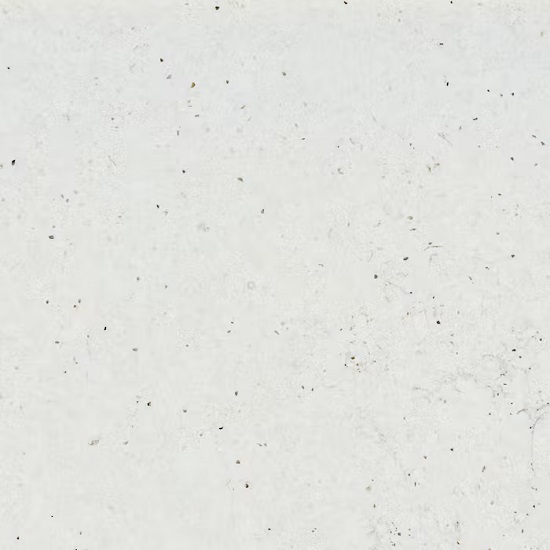

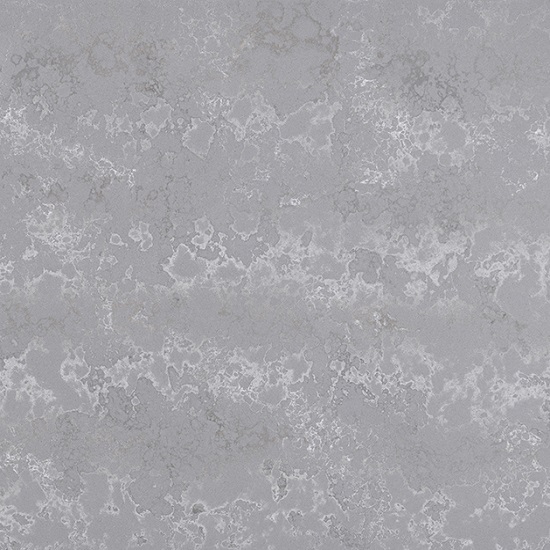

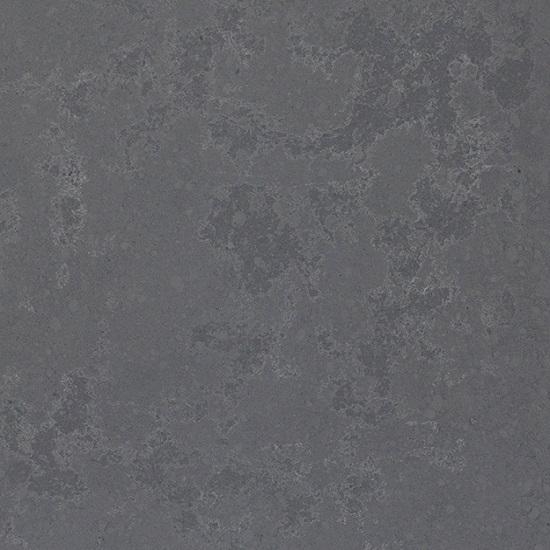

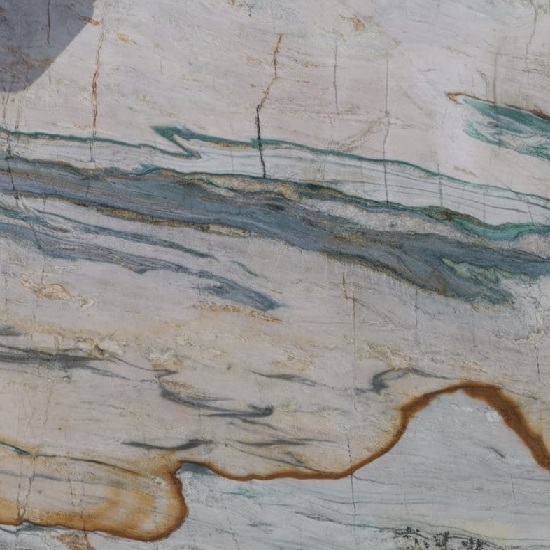

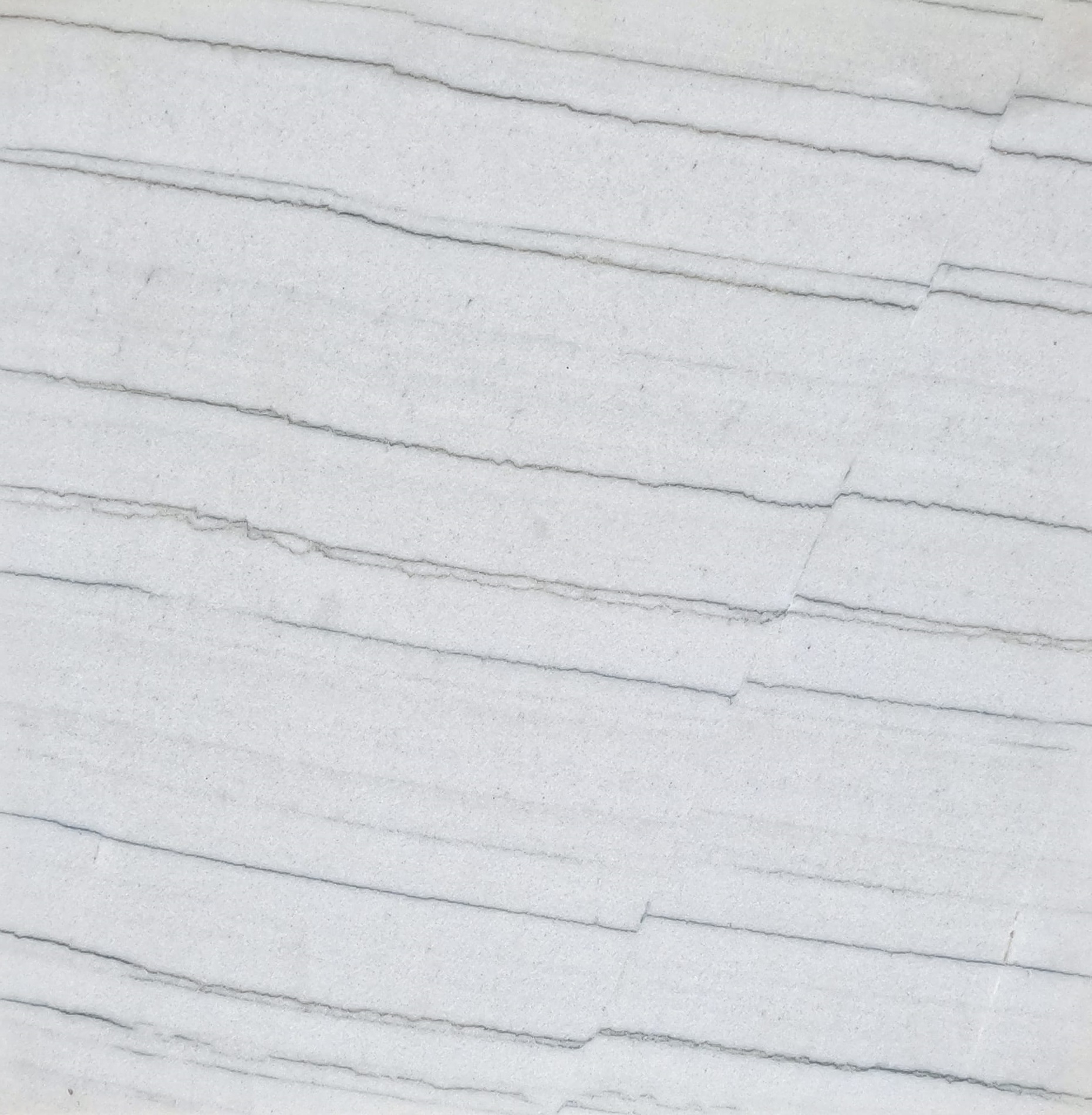

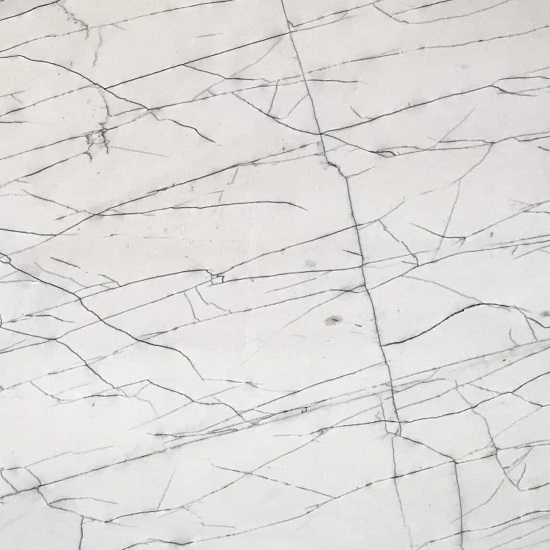

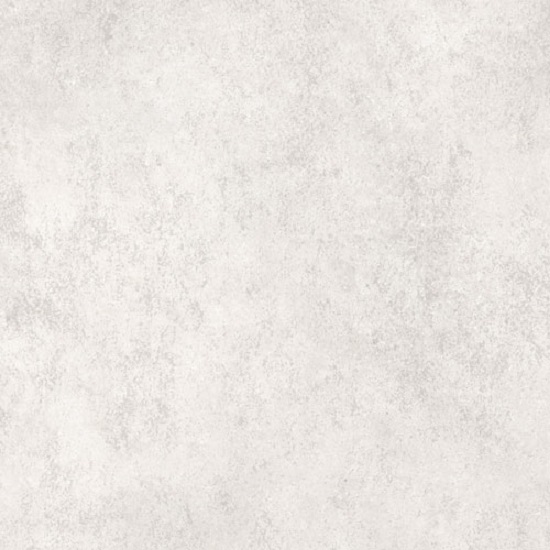

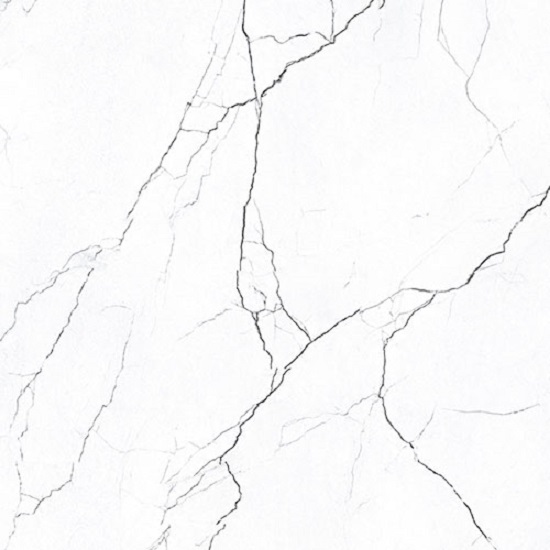

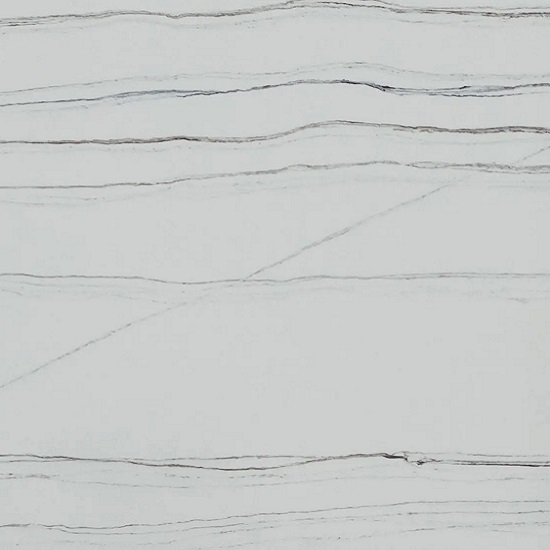

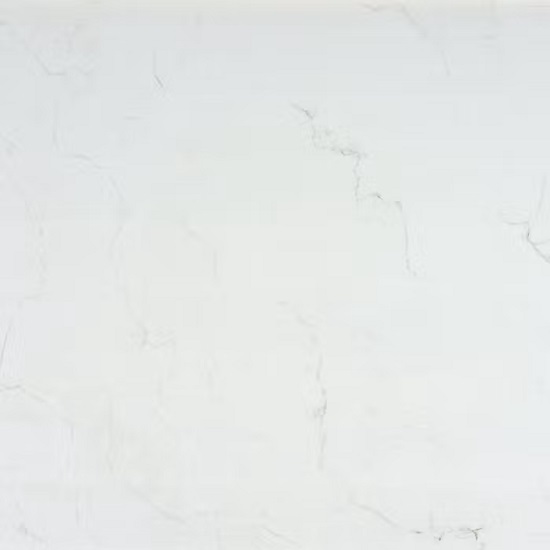

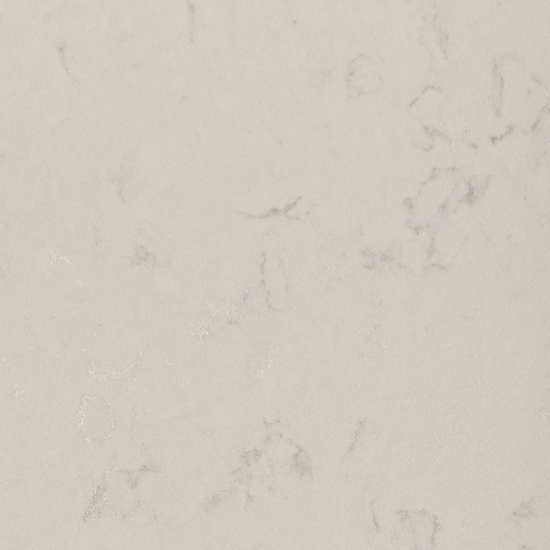

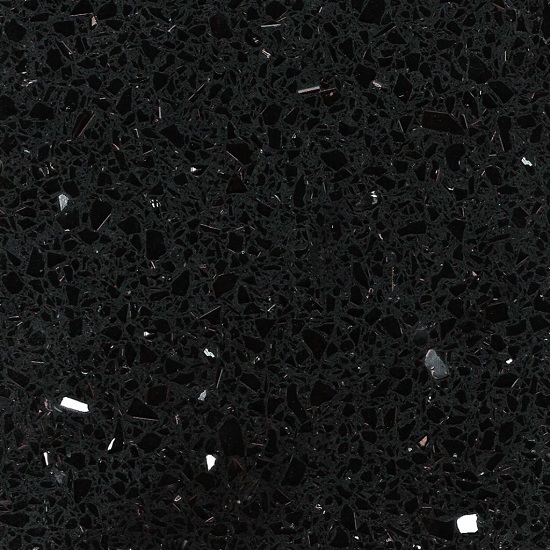

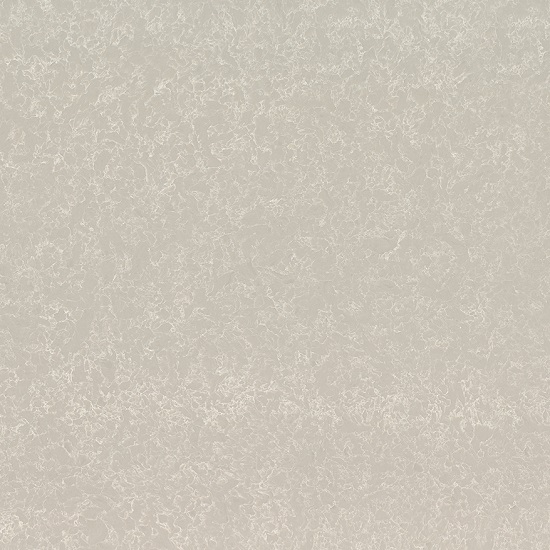

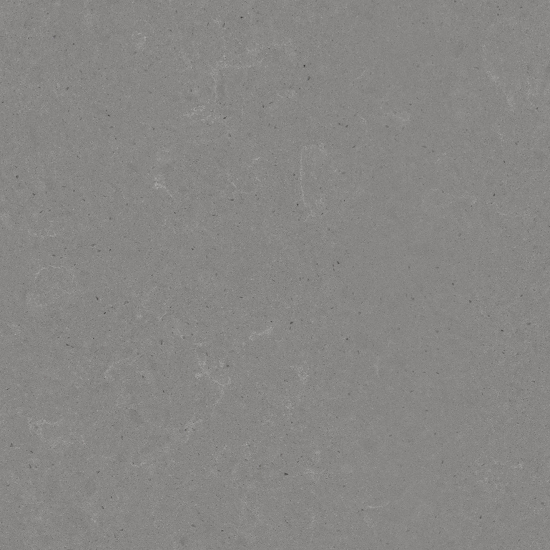

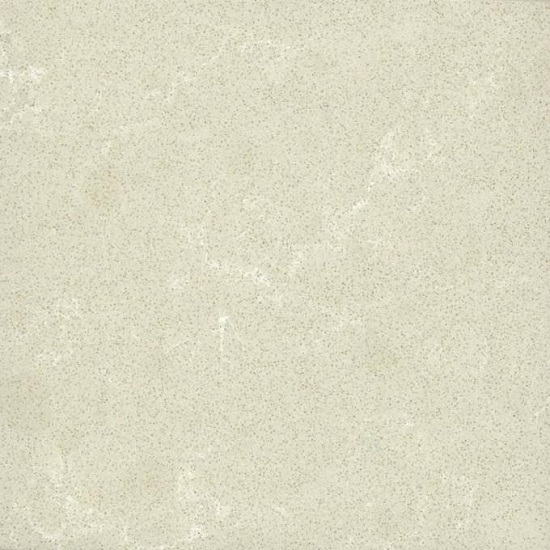

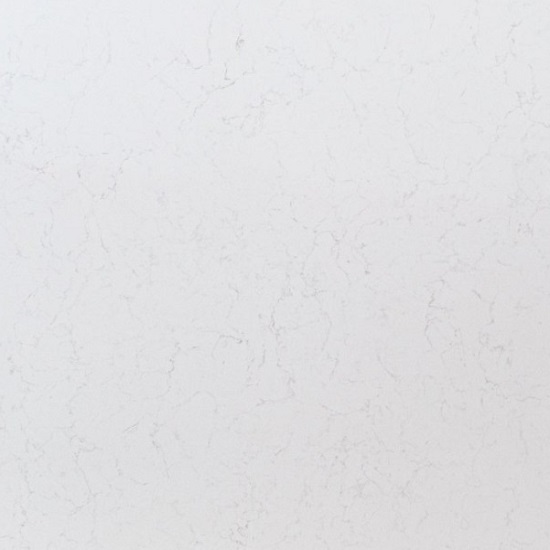

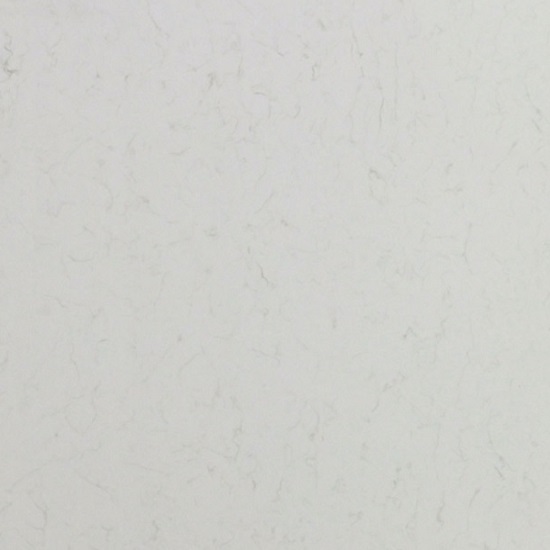

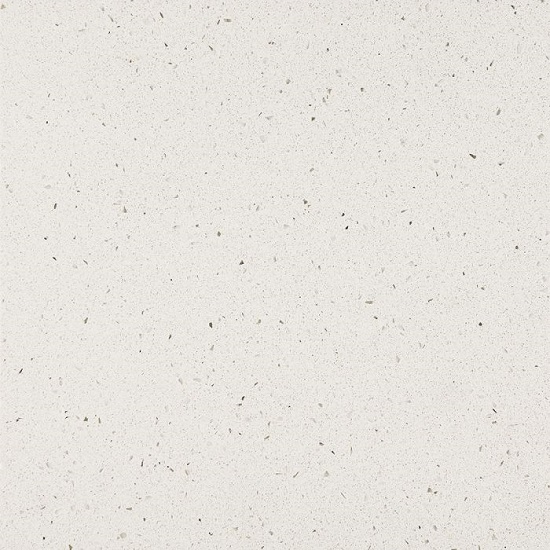

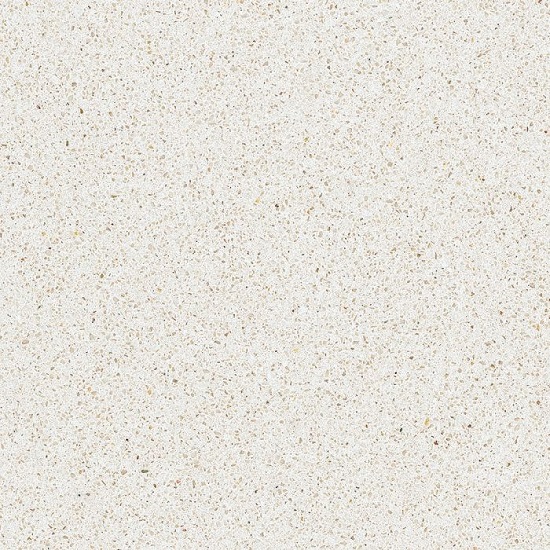

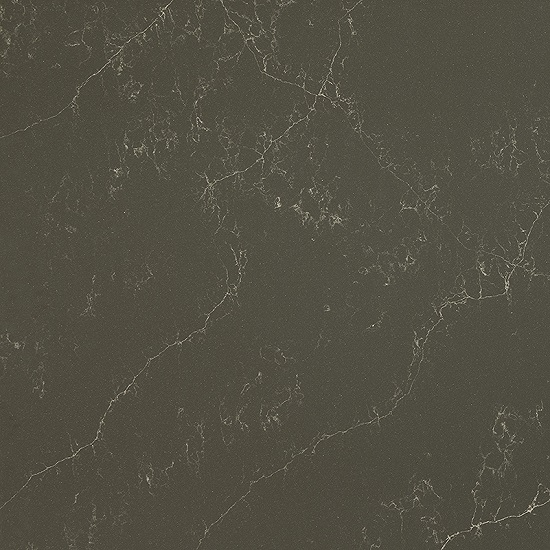

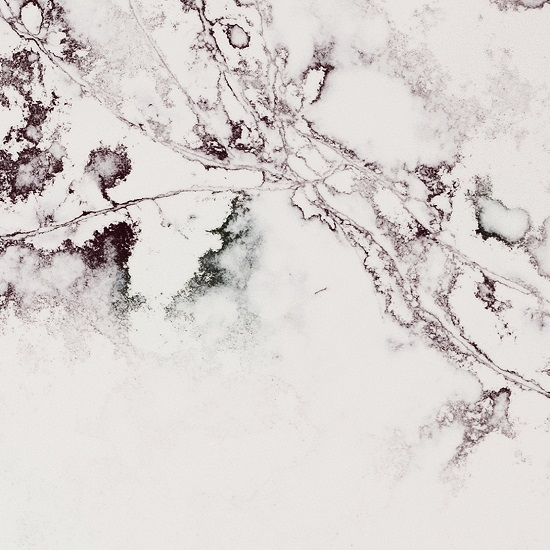

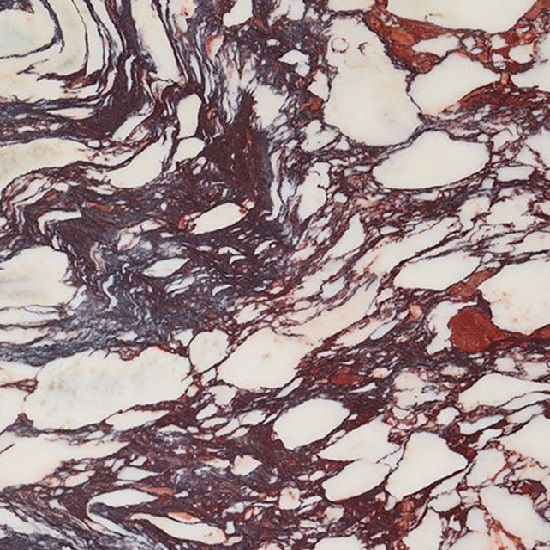

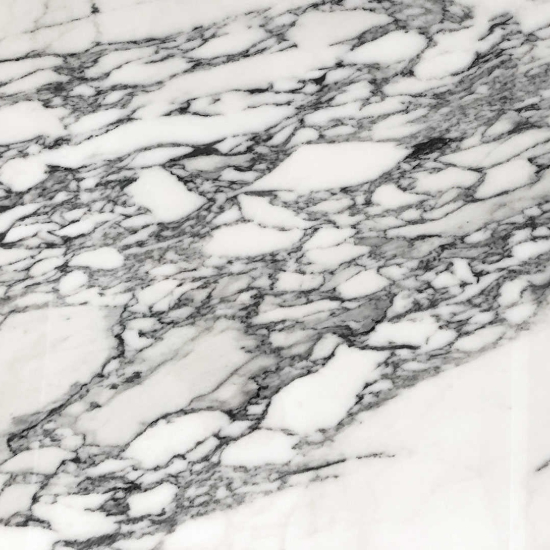

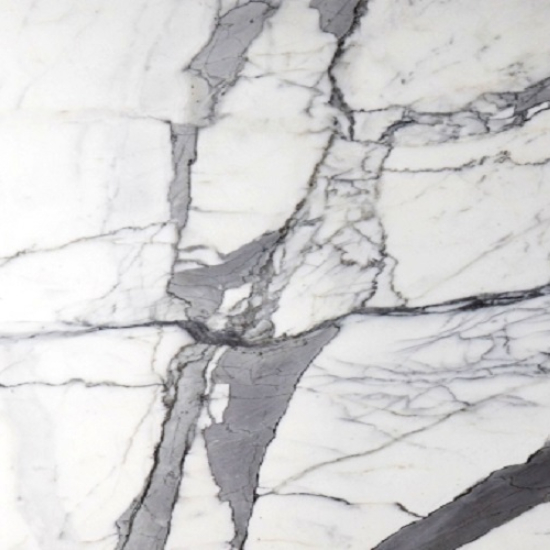

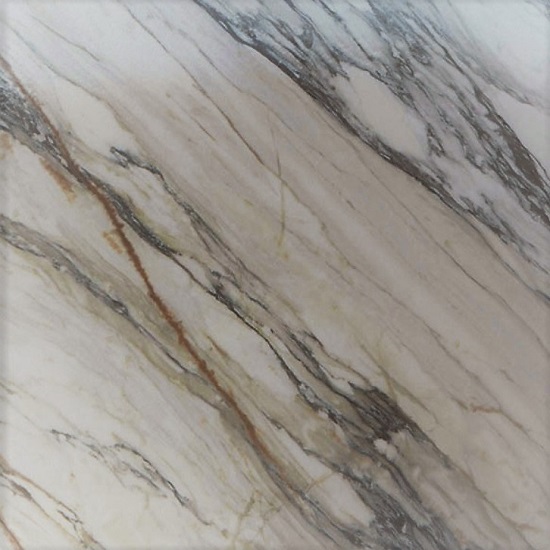

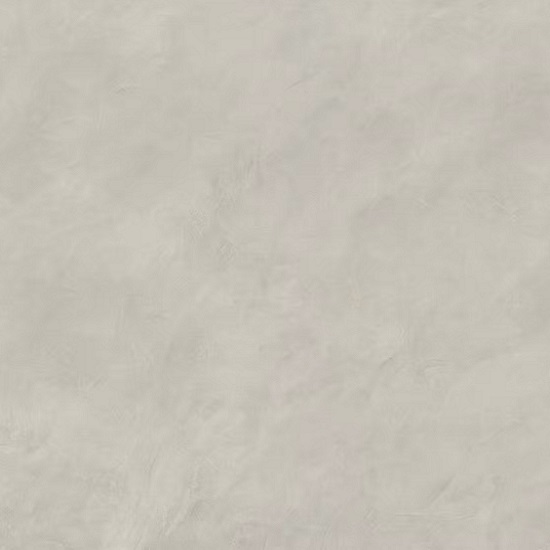

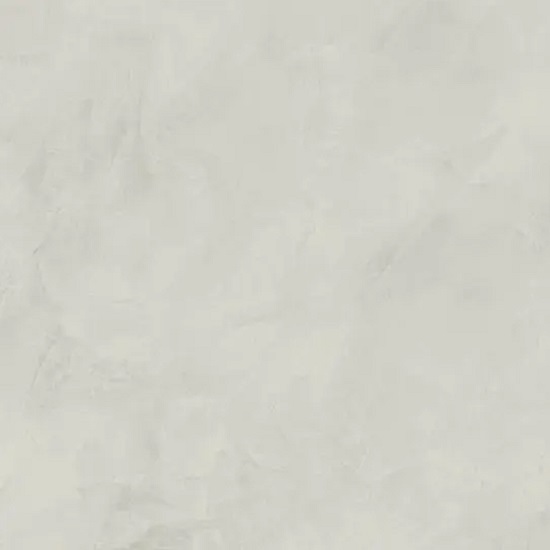

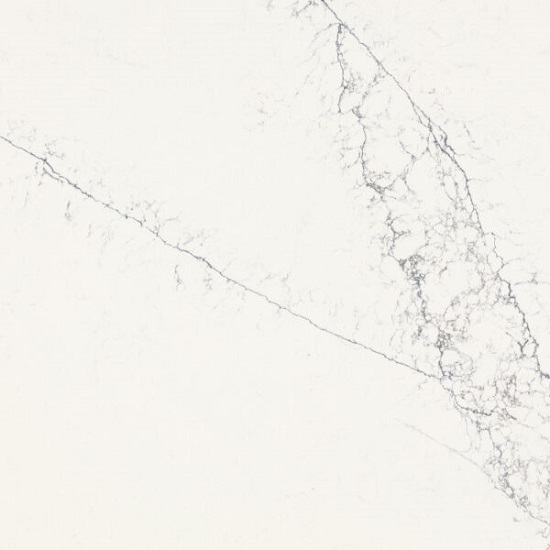

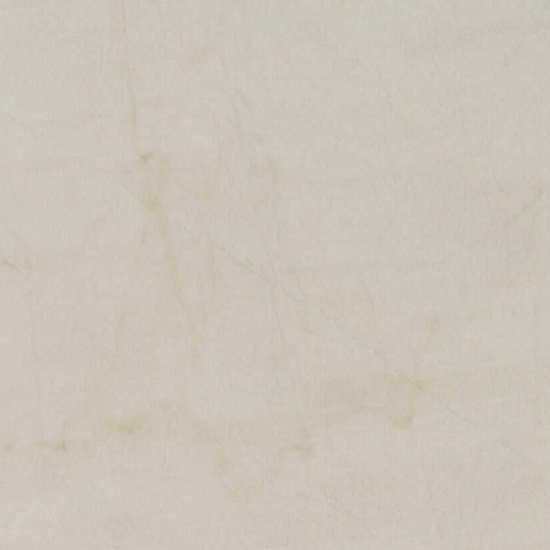

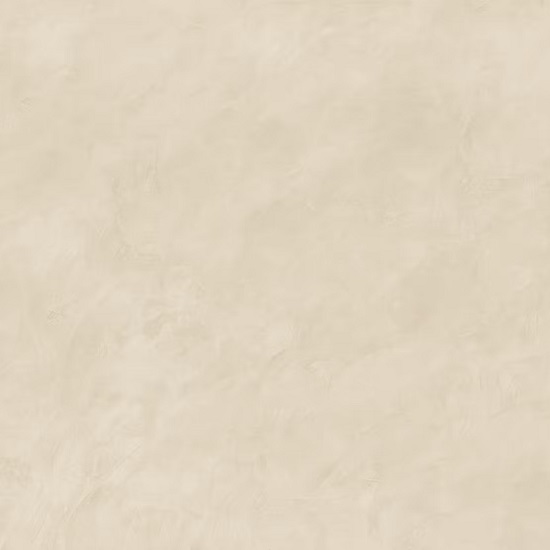

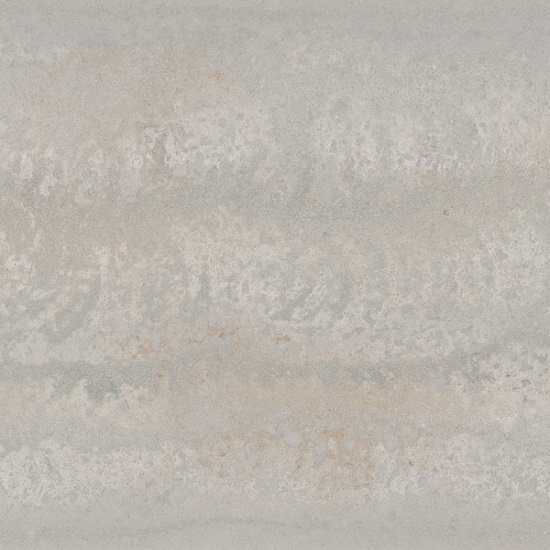

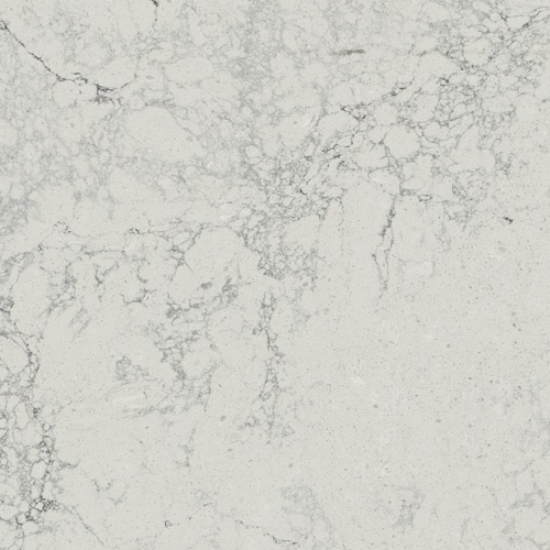

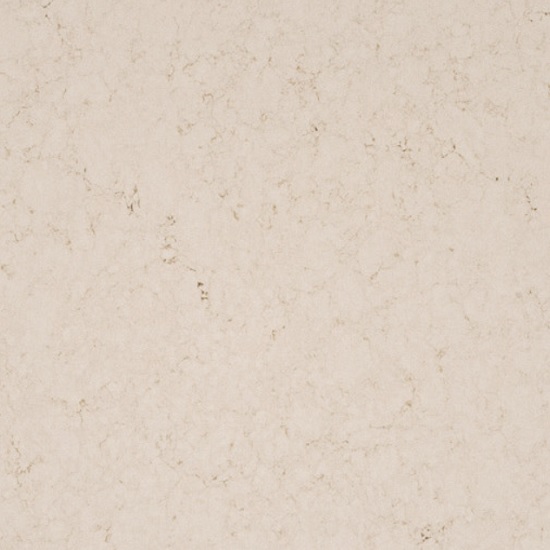

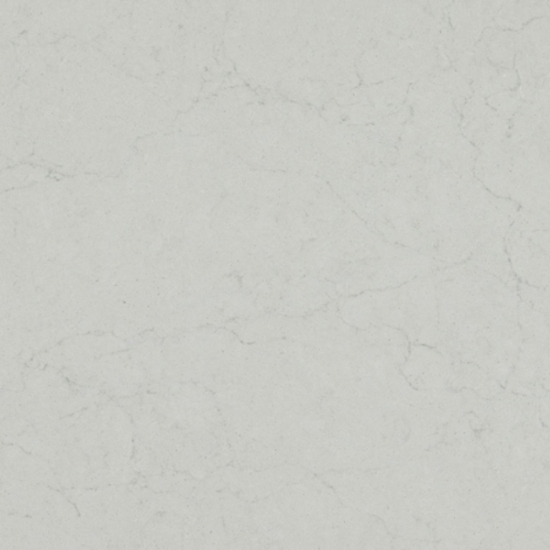

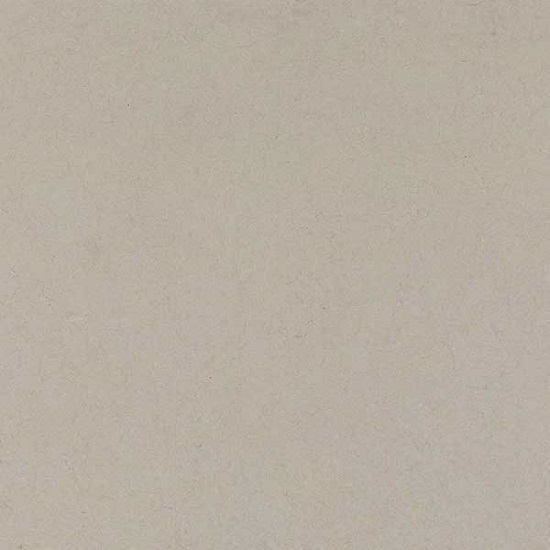

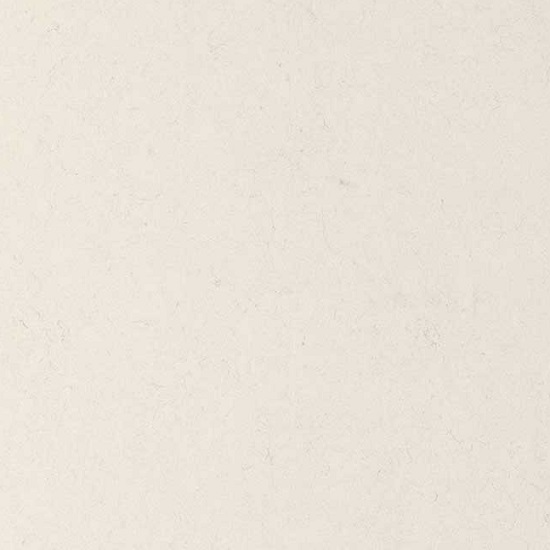

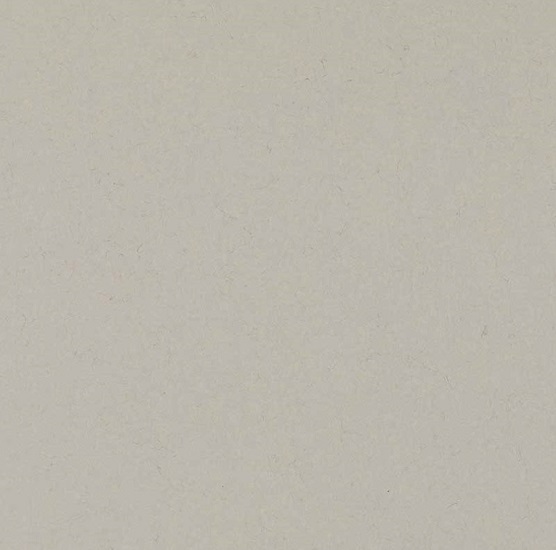

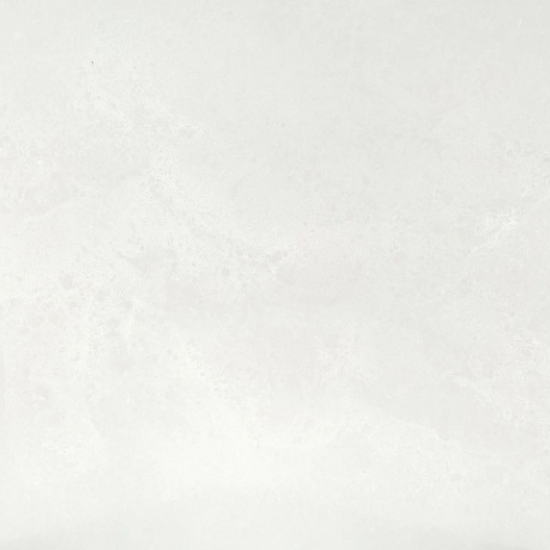

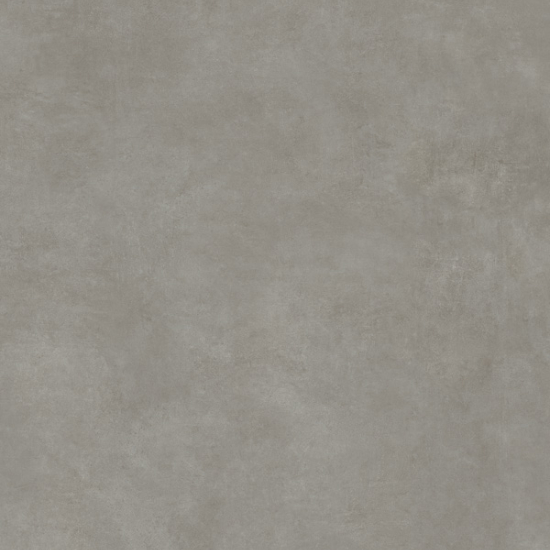

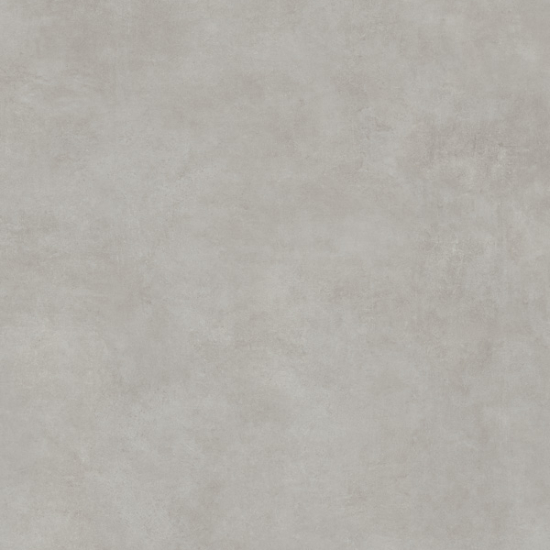

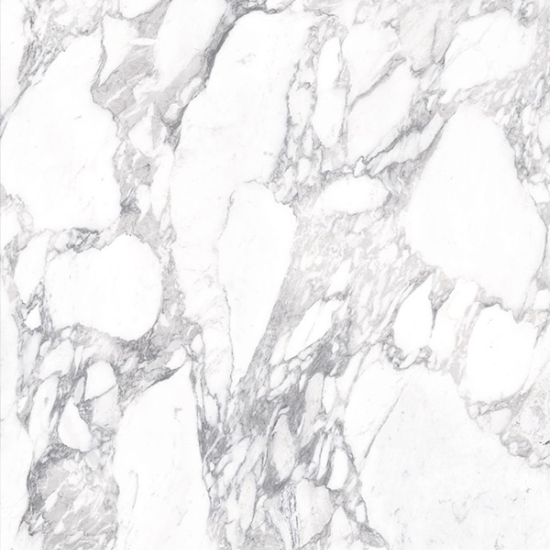

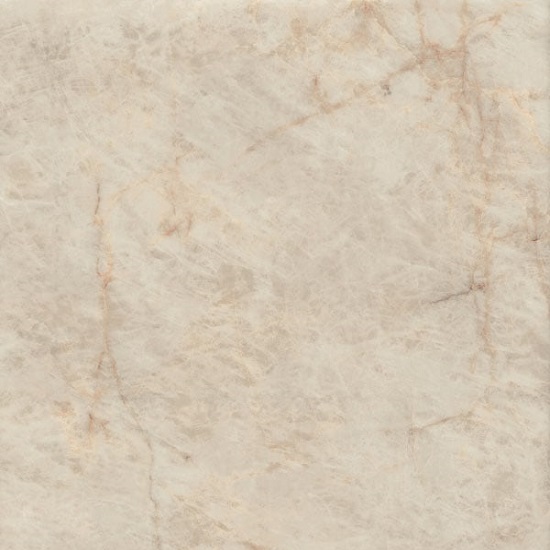

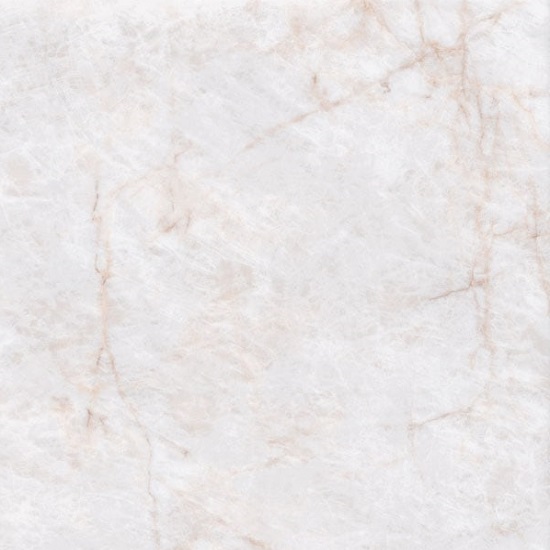

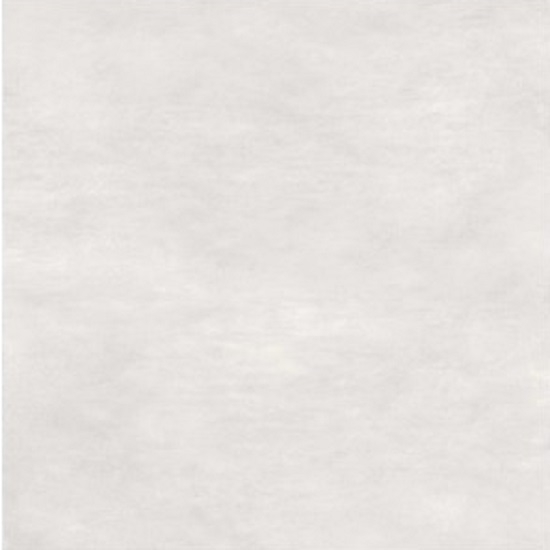

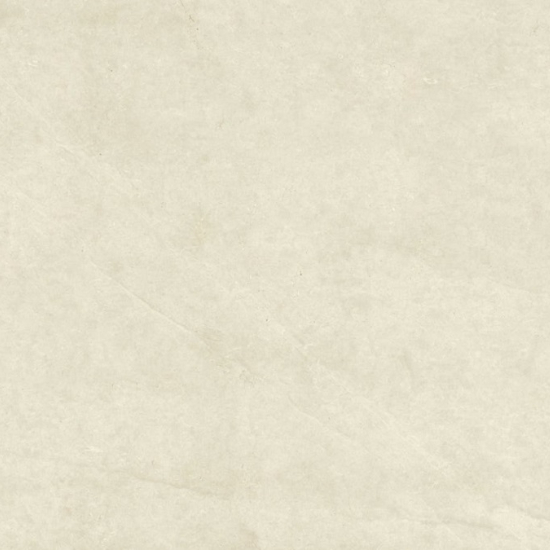

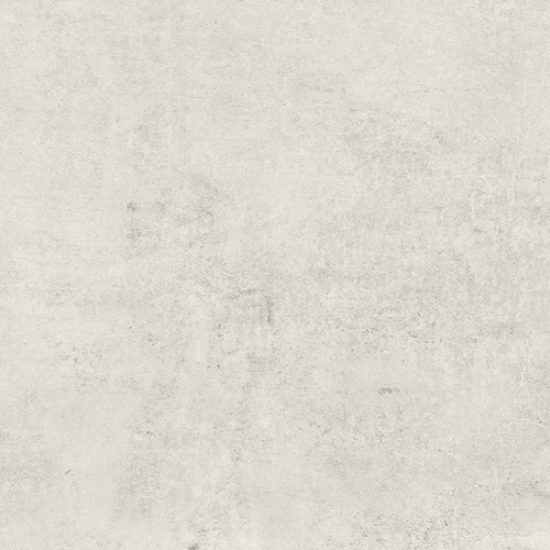

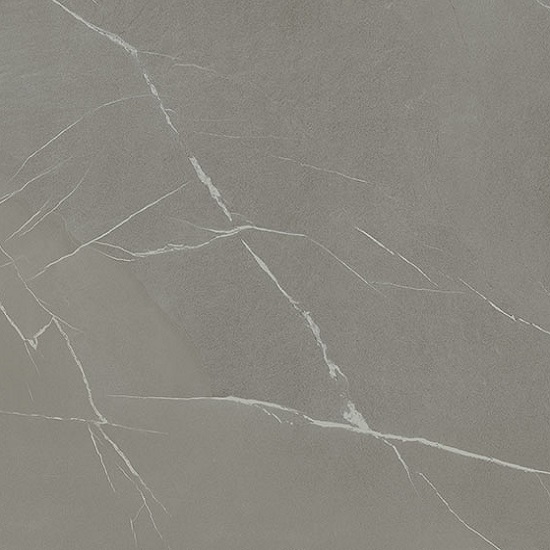

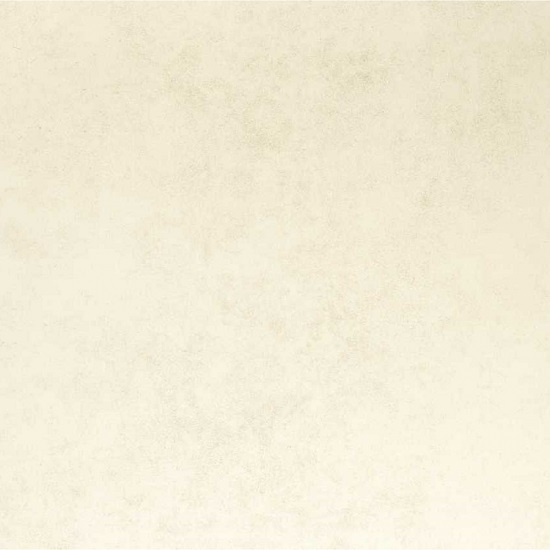

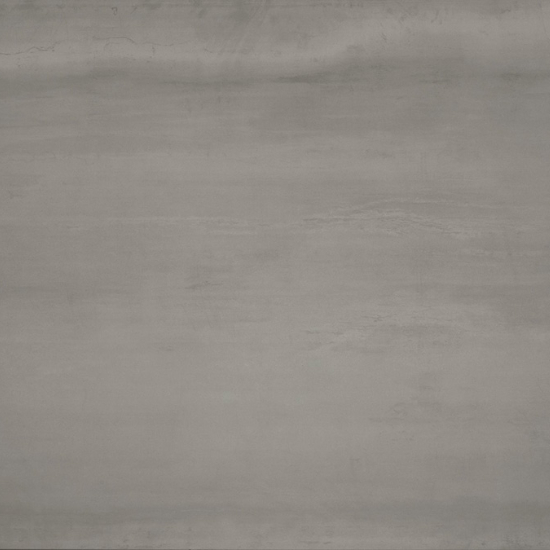

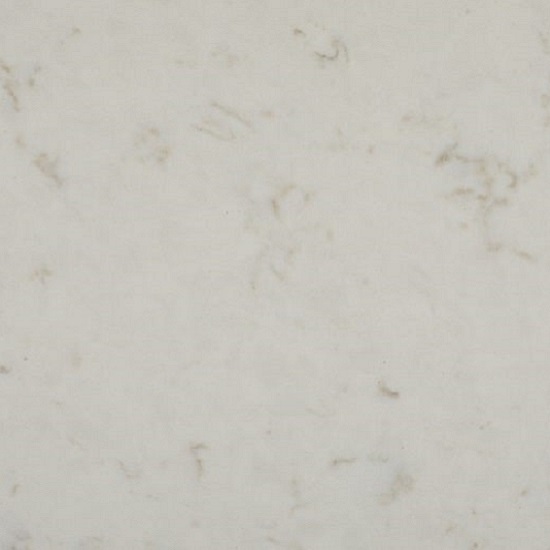

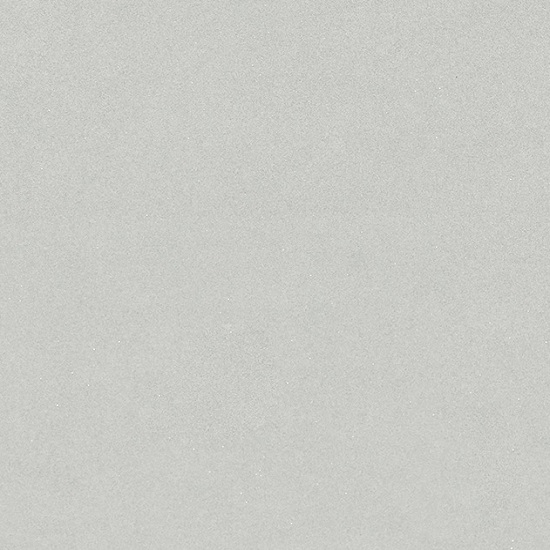

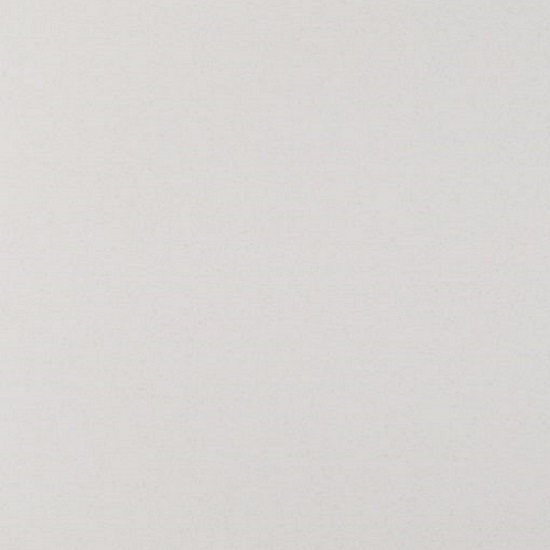

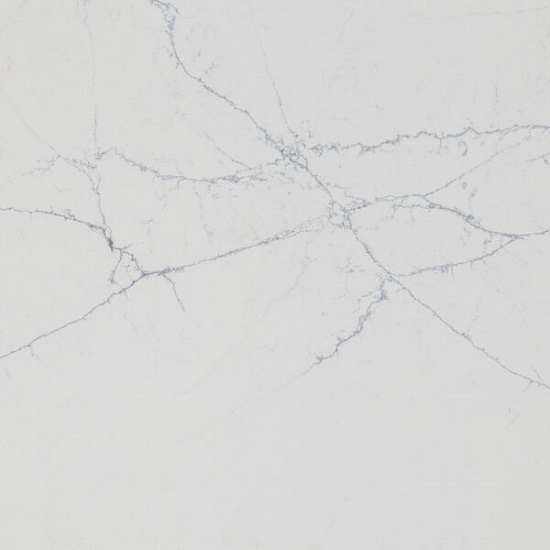

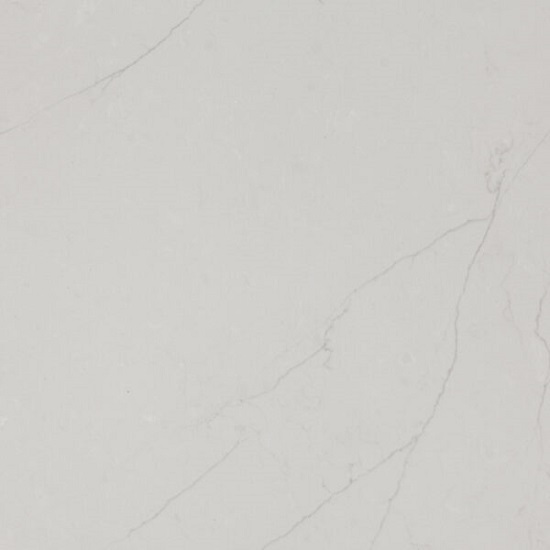

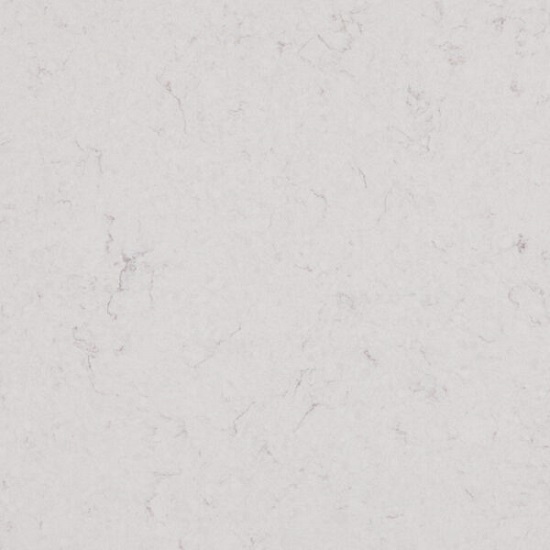

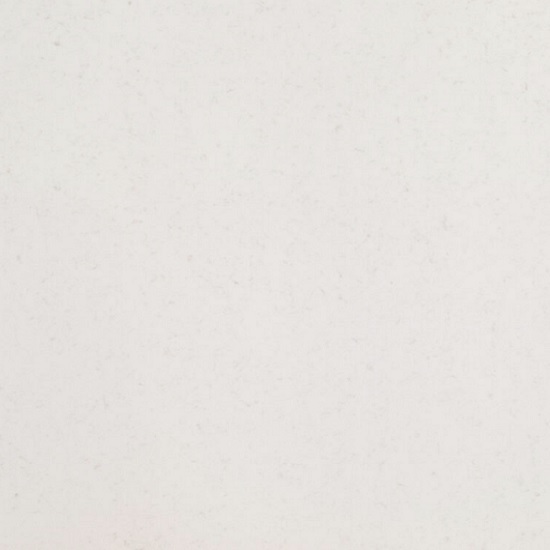

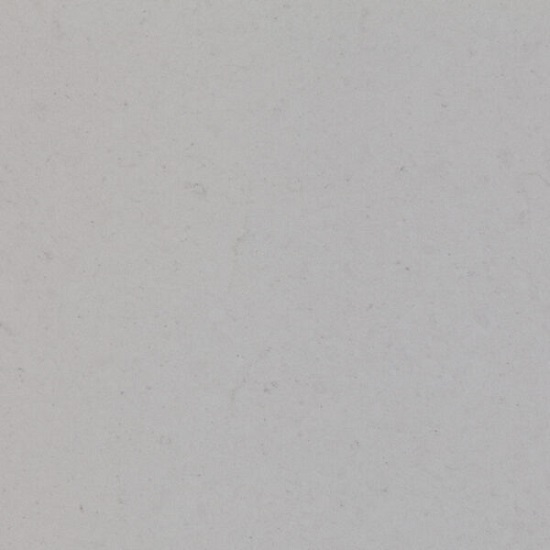

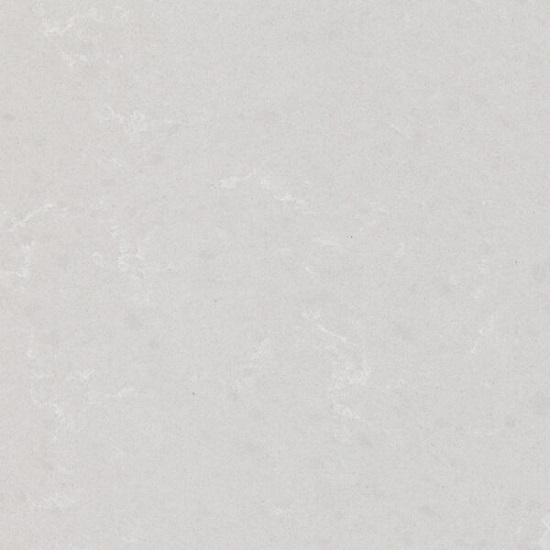

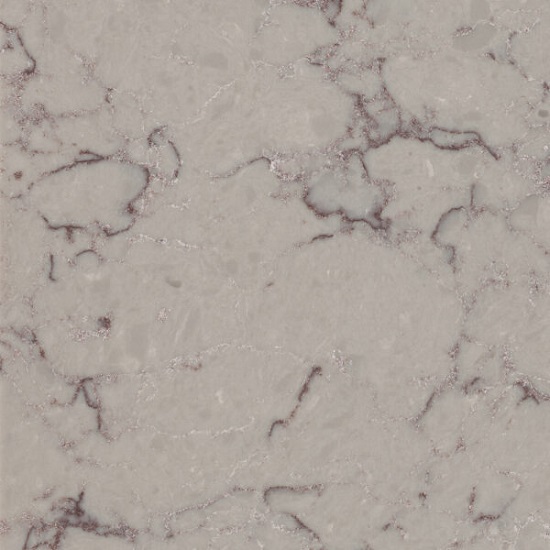

Marazzi Lasa has a white crystalline background with prominent pinkish-grey veins. In addition, one or two prominent broad grey veins are interspersed throughout the gentle blend of whites, roses, and greys.

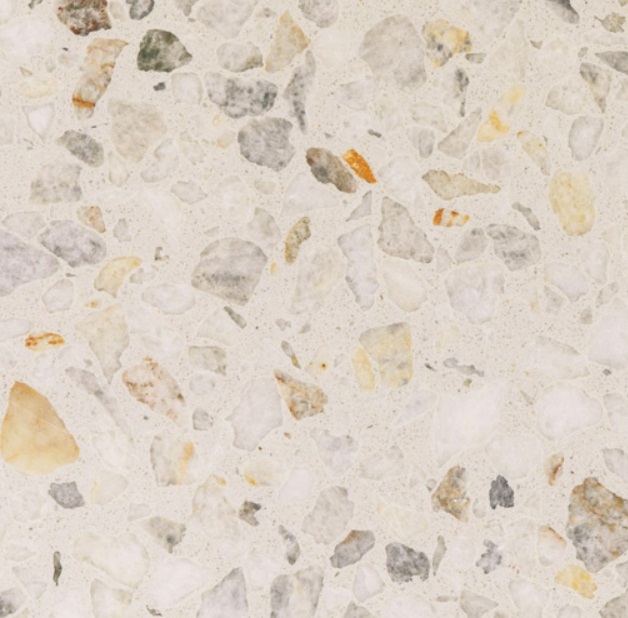

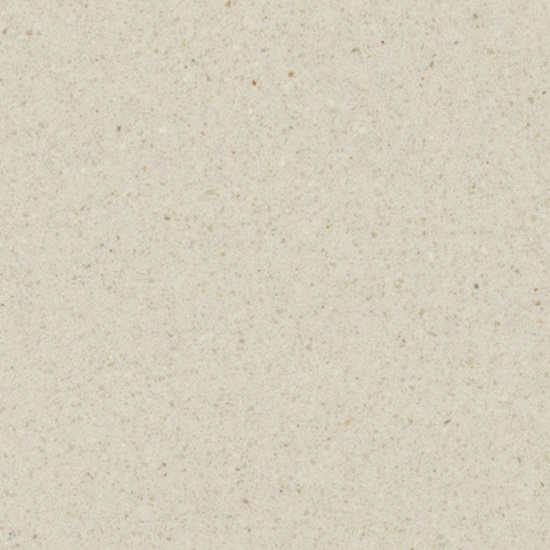

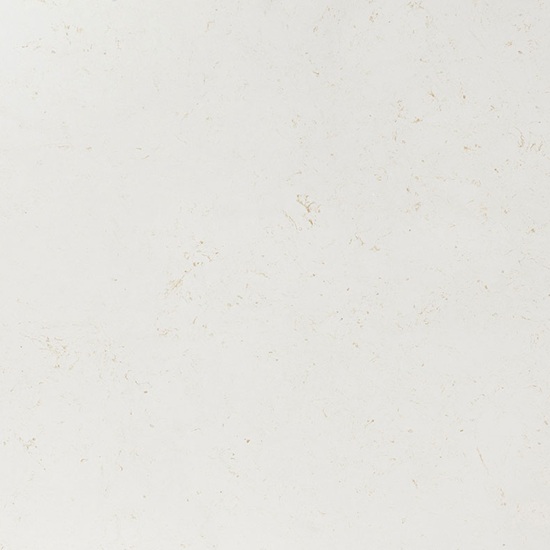

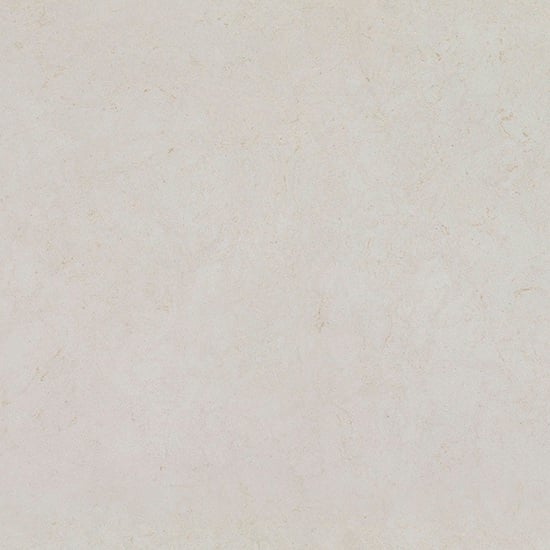

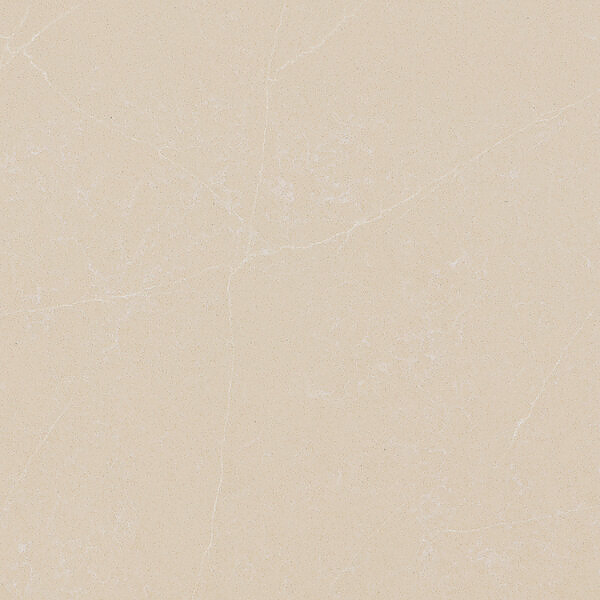

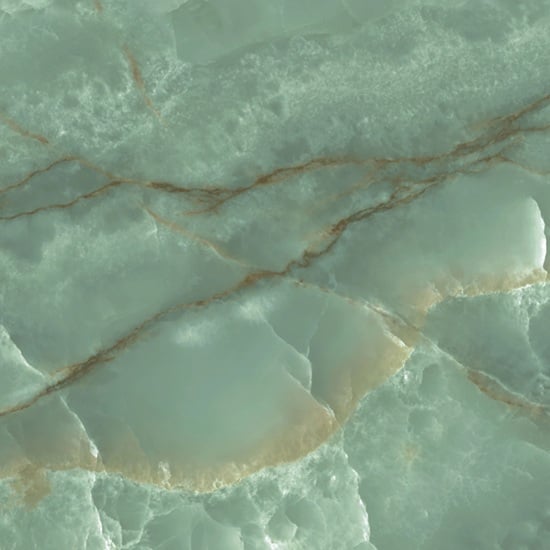

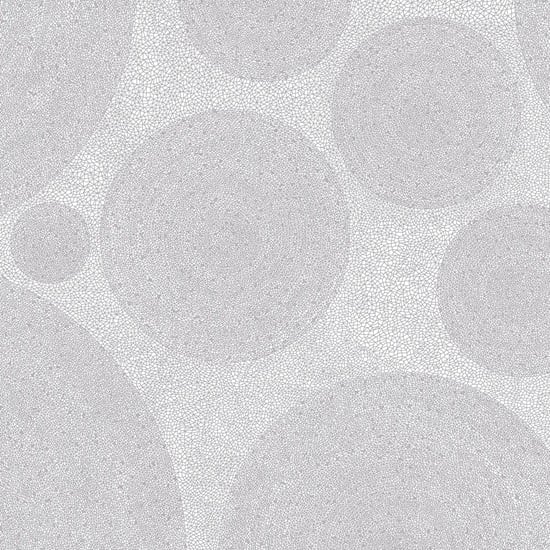

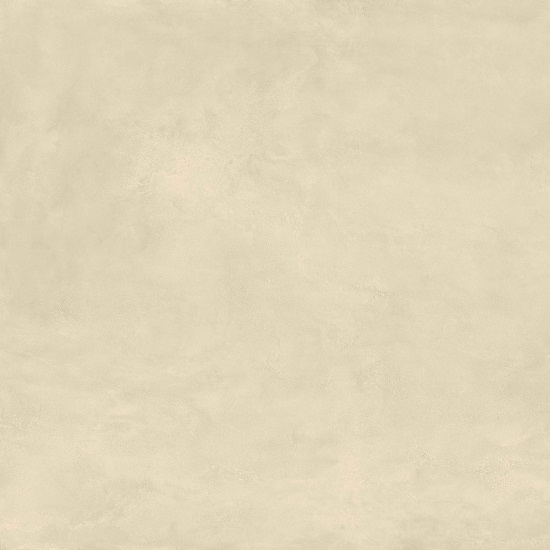

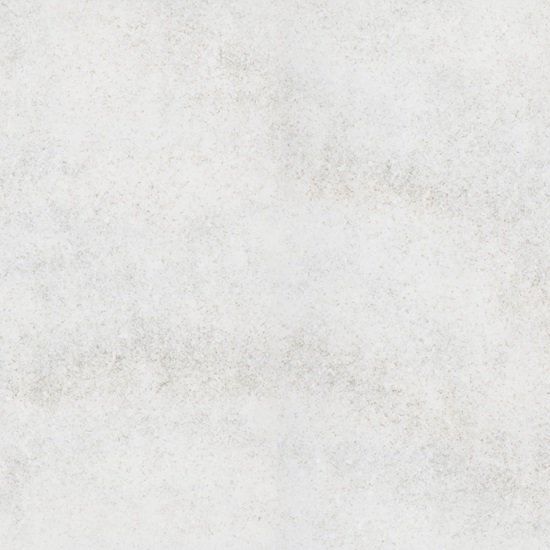

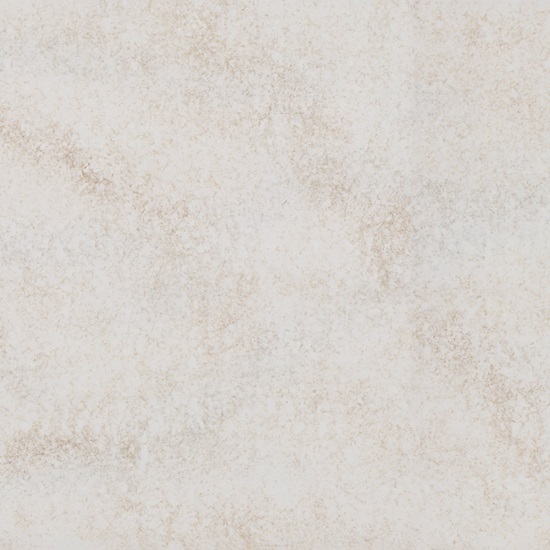

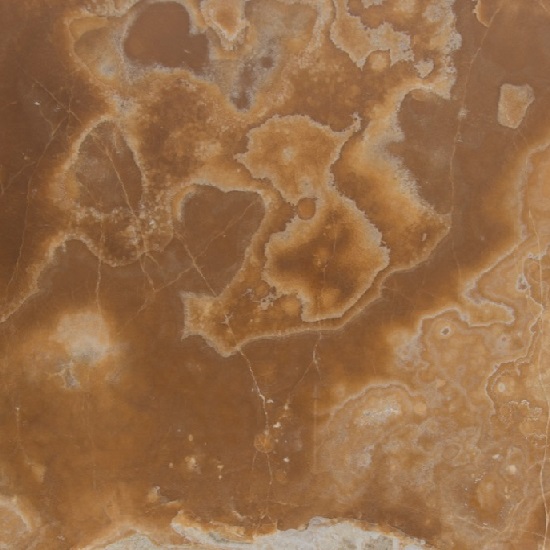

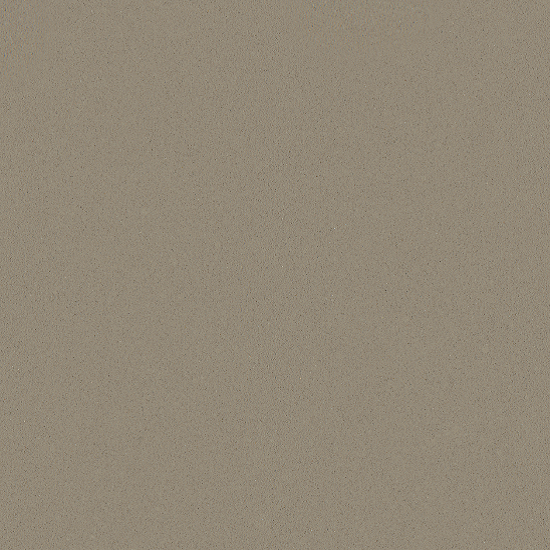

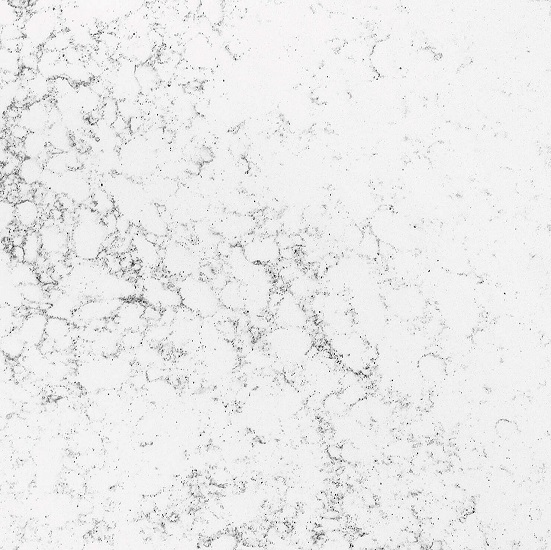

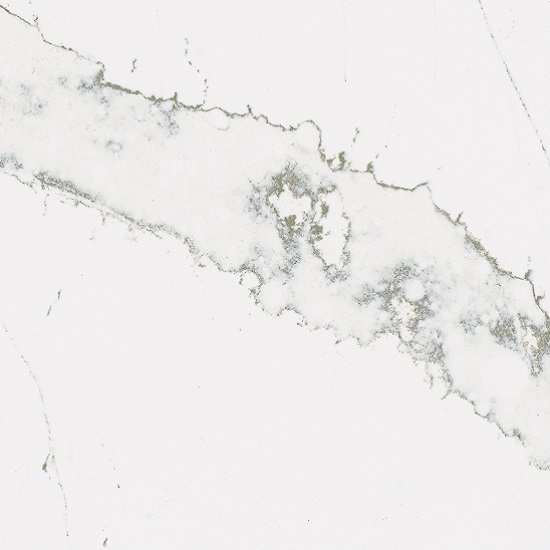

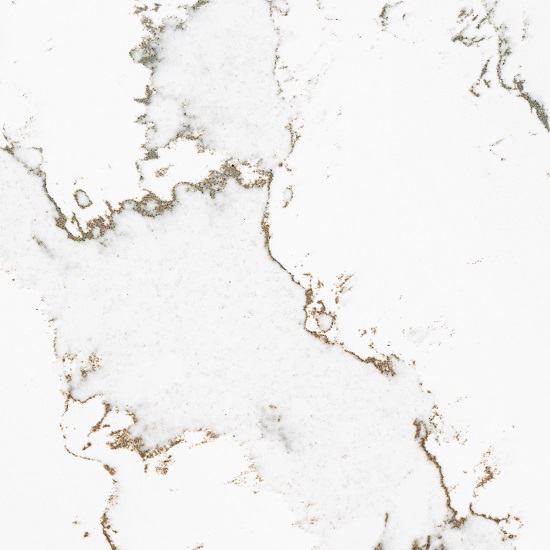

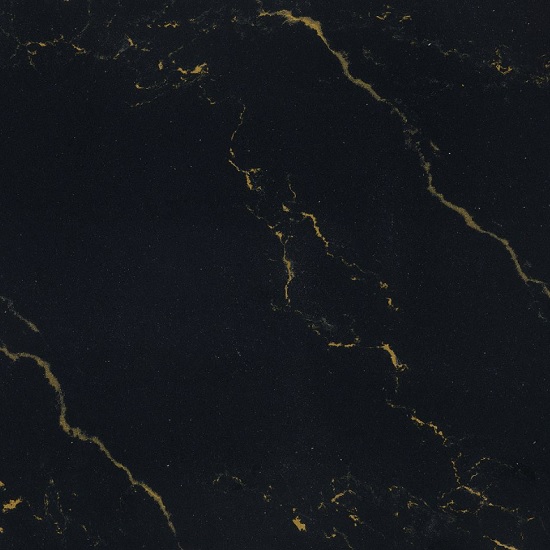

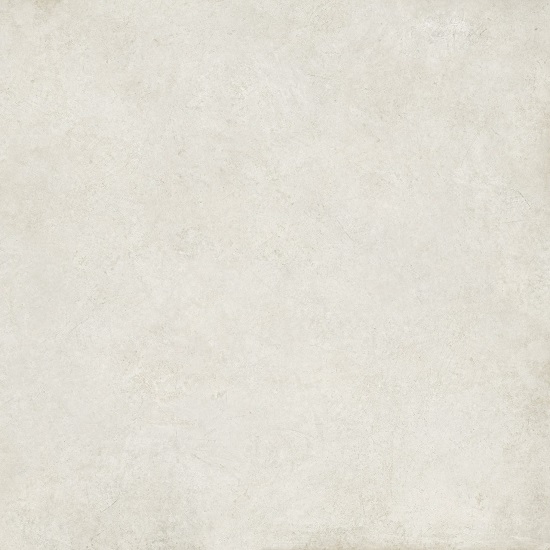

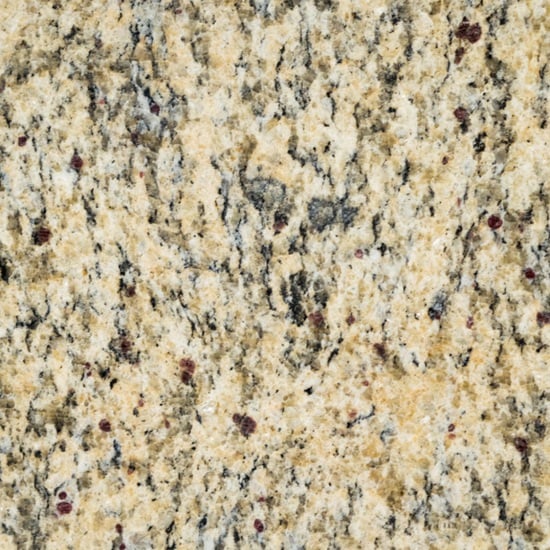

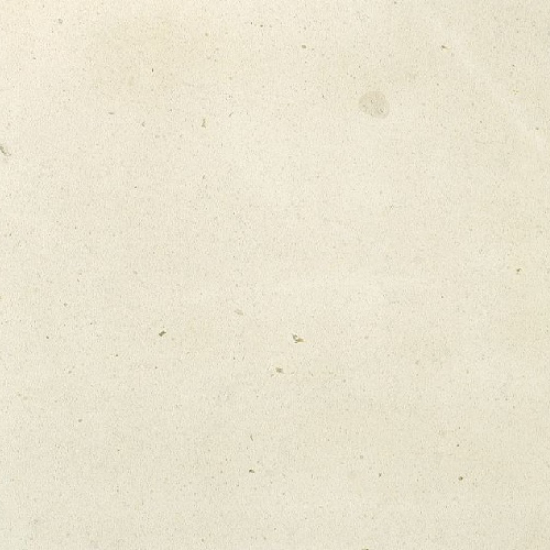

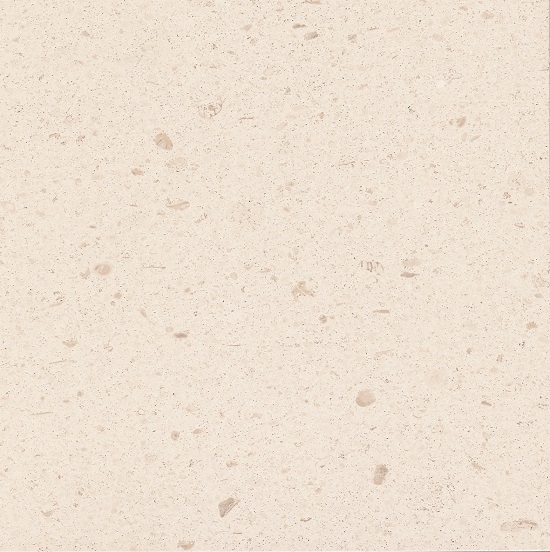

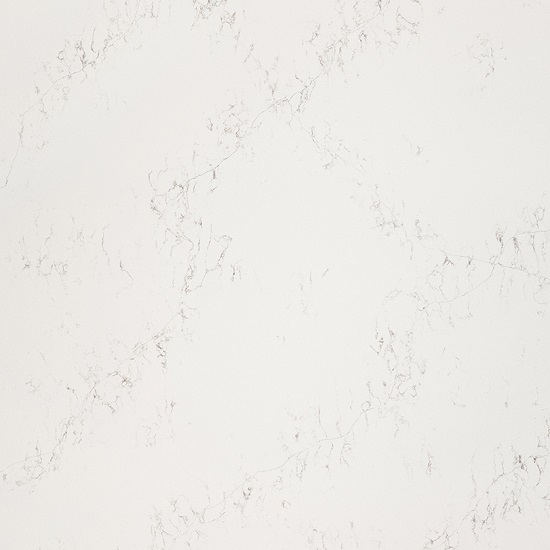

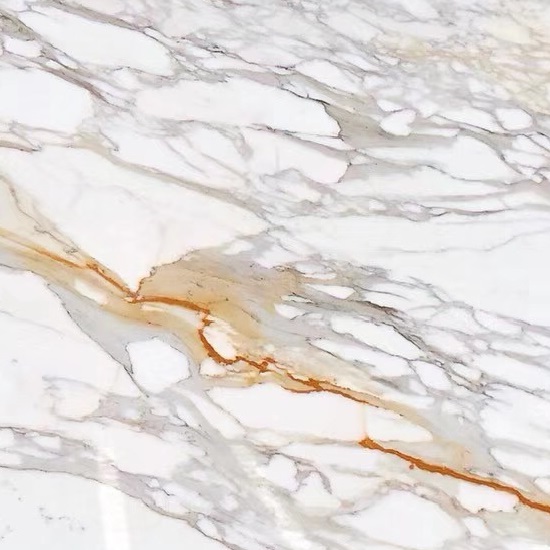

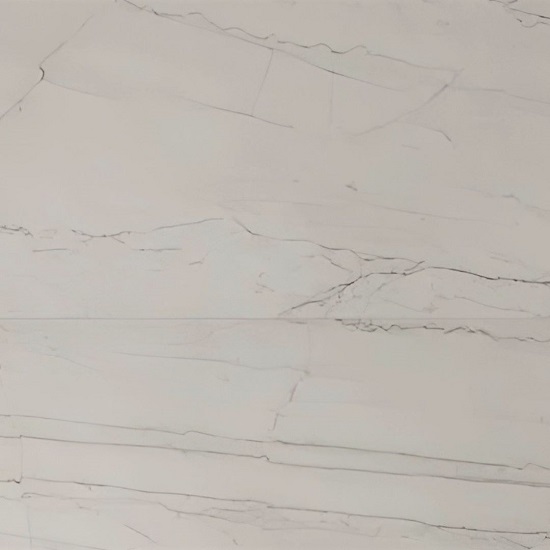

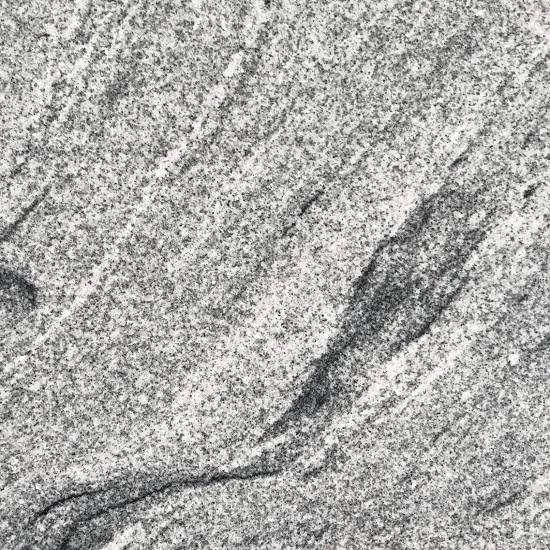

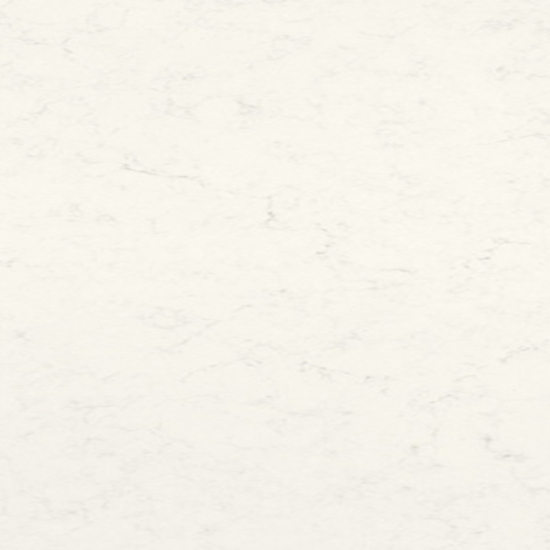

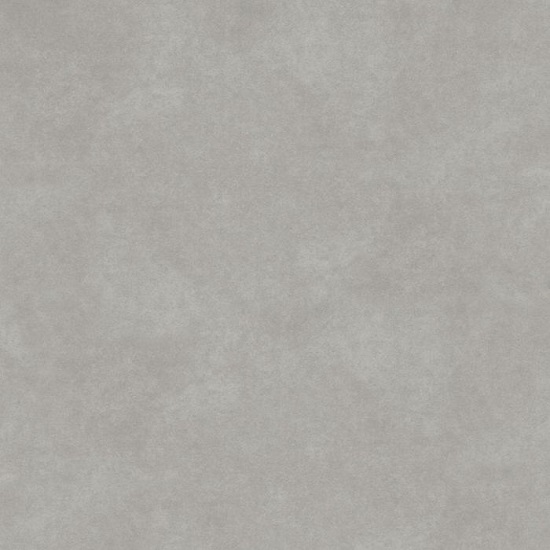

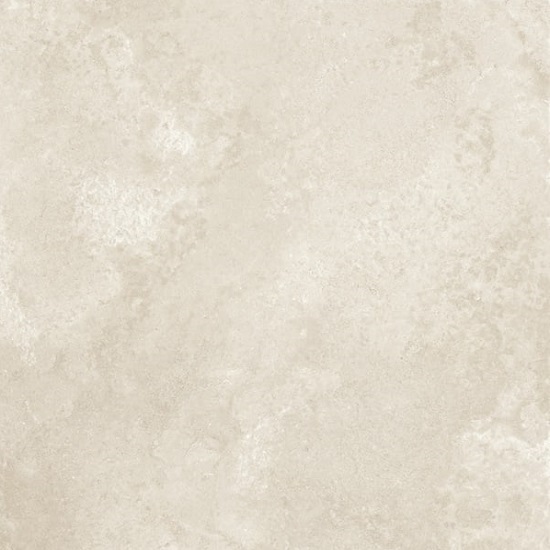

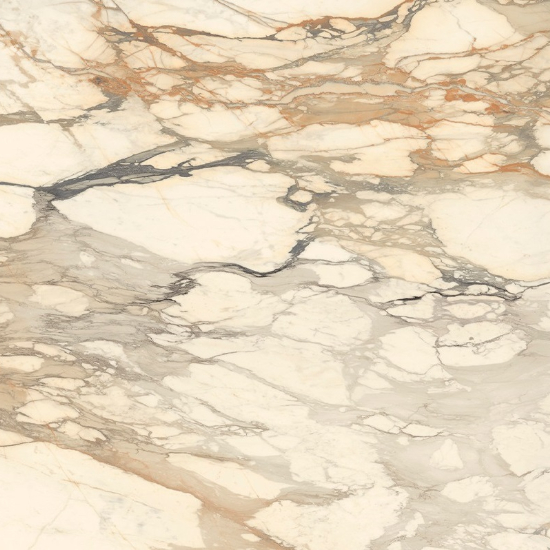

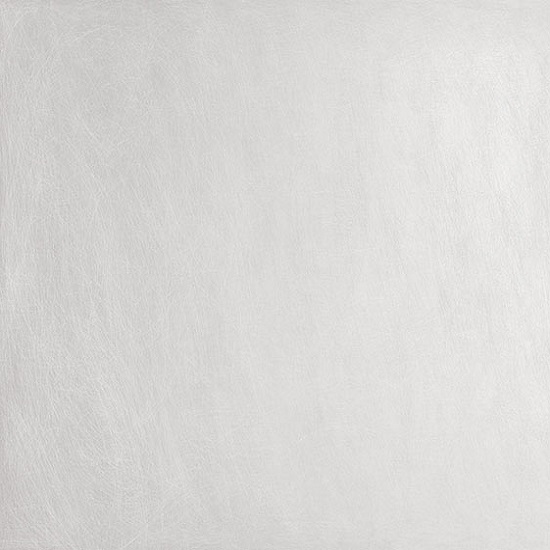

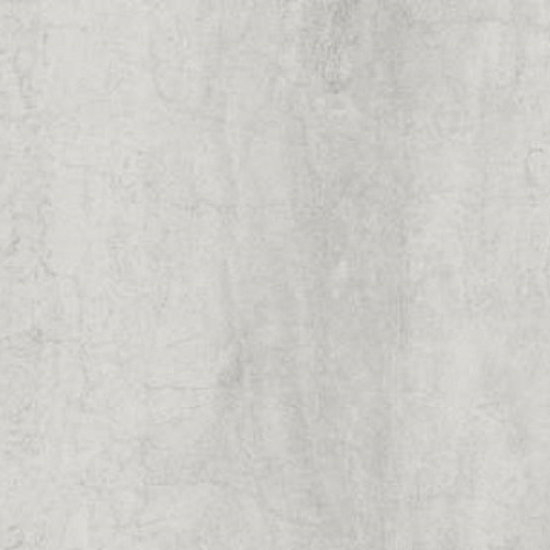

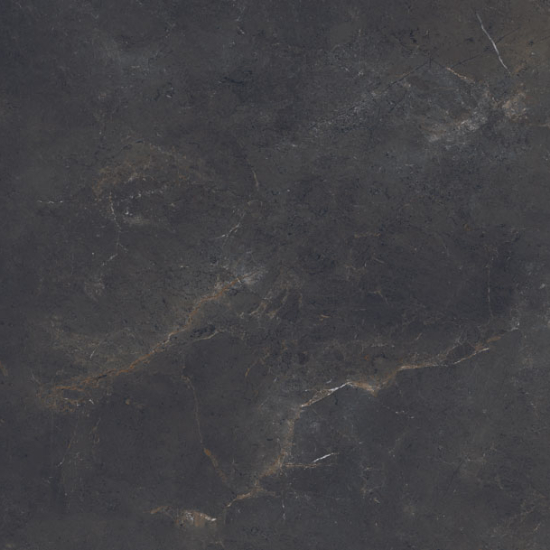

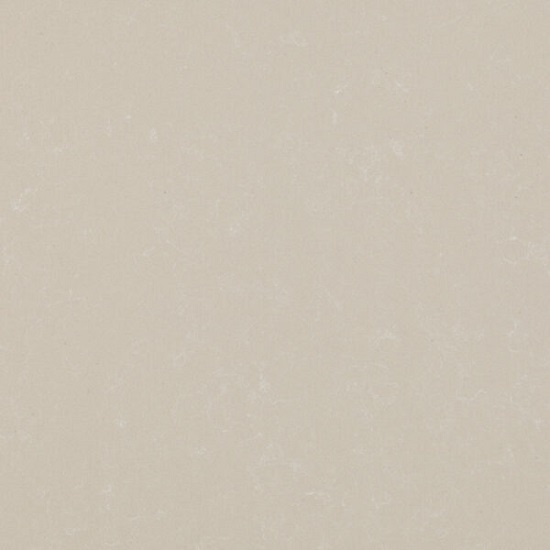

This white-creamy background sintered stone with gentle golden veining complements a broad spectrum of tones and patterns. Consistent grey and yellow spots veins on a crisp white backdrop are the perfect textures for the boldest and most spectacular projects.

You Can Use Marazzi Lasa As a Kitchen Island & Breakfast Bar

A Marazzi worktop offers stain resistance, scratch resistance, and UV ray resistance, making it suitable indoors and outdoors. In addition, The Top surfaces boast unmatched water resistance, impact resistance, and heat resistance, making them a perfect option for kitchens, bathrooms, saunas, spas, and other areas in continuous contact with water.

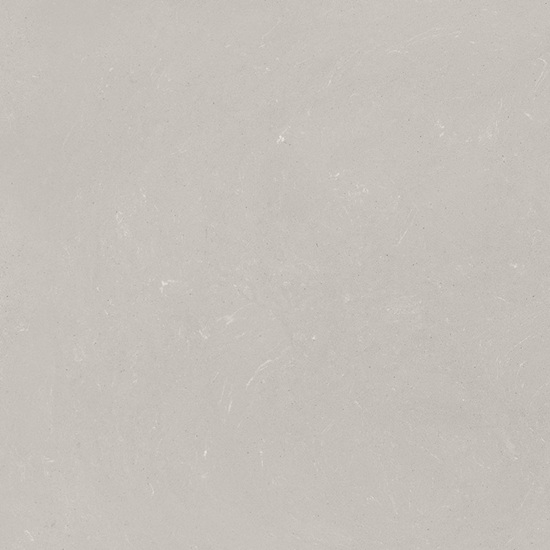

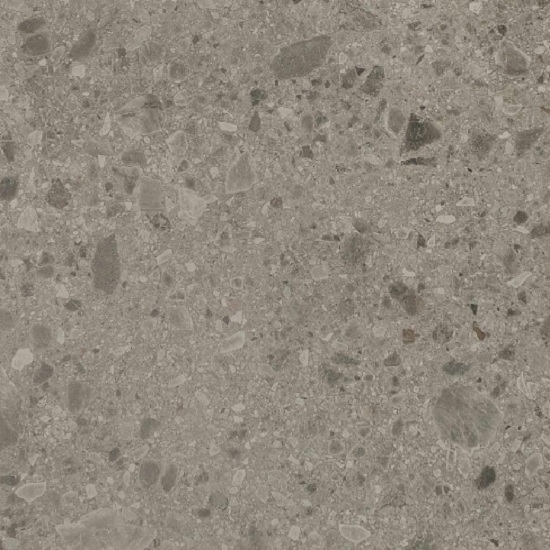

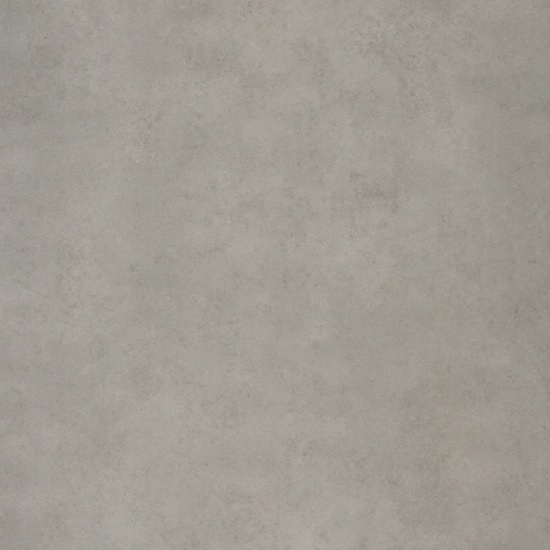

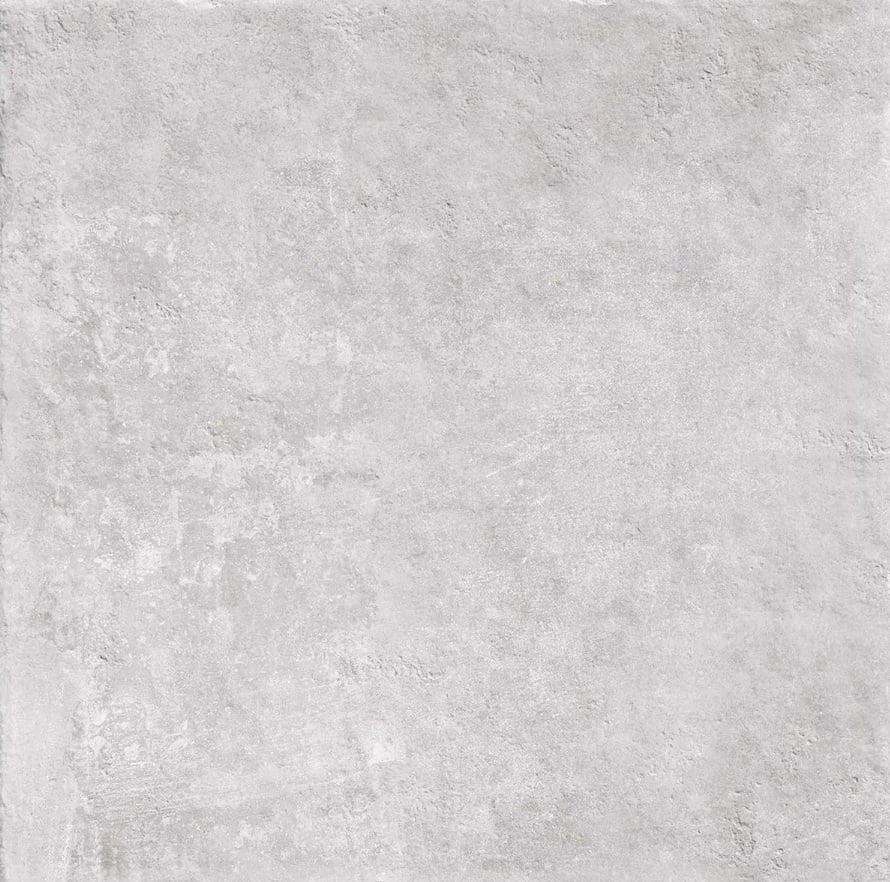

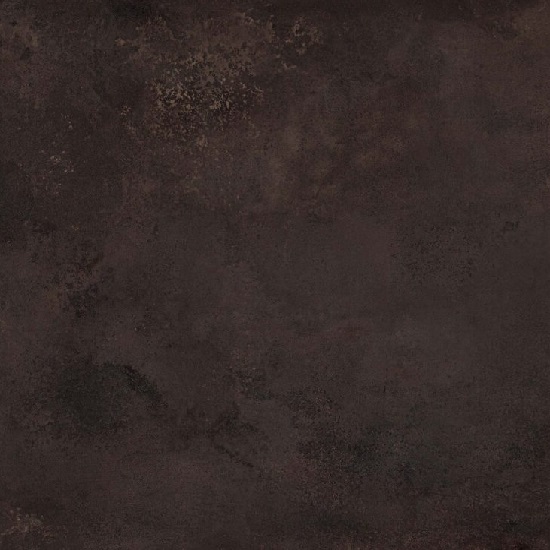

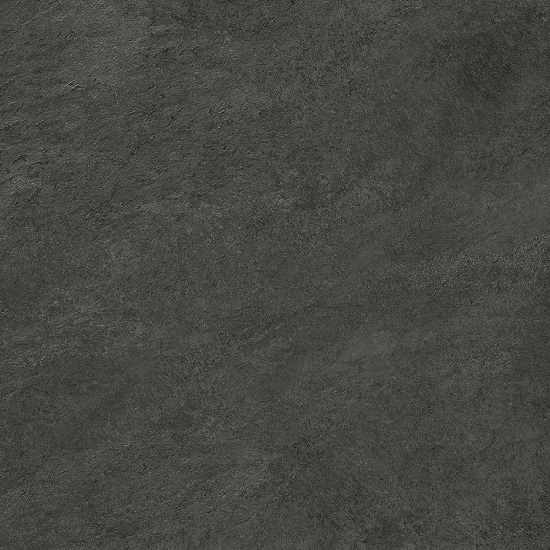

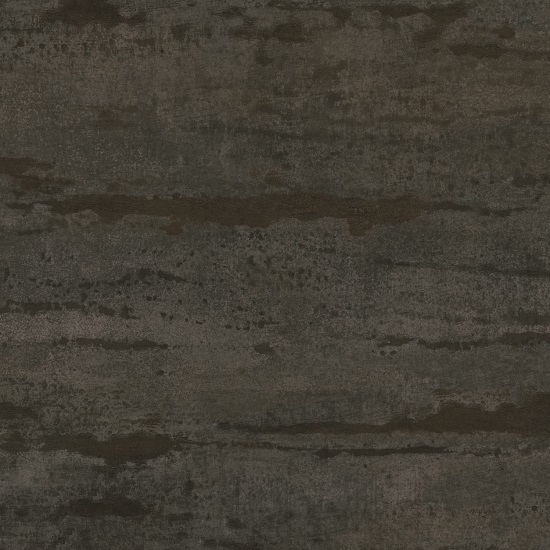

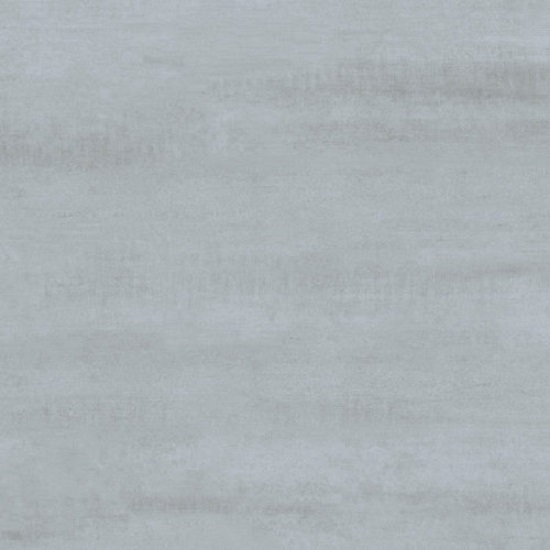

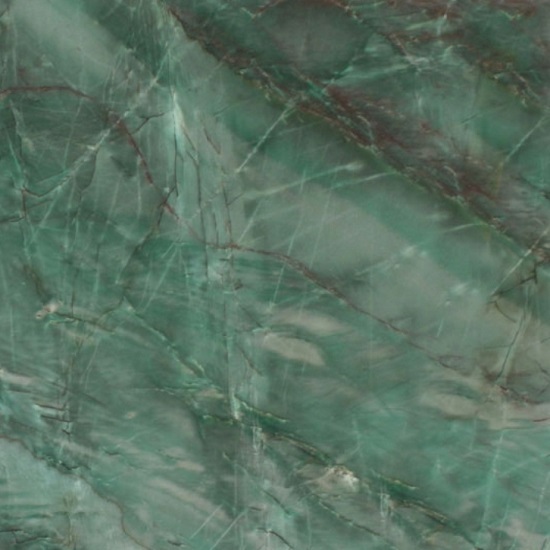

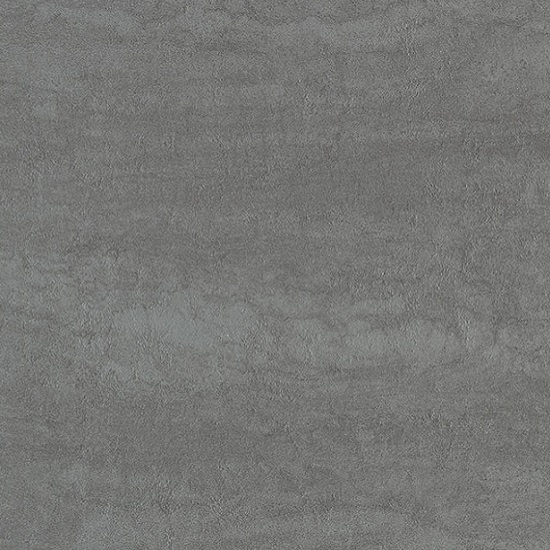

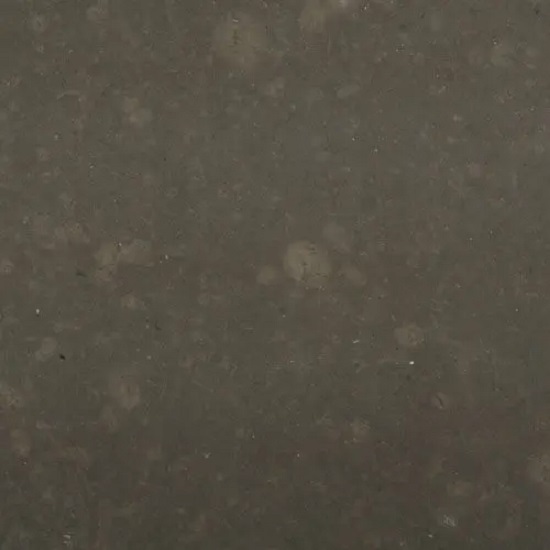

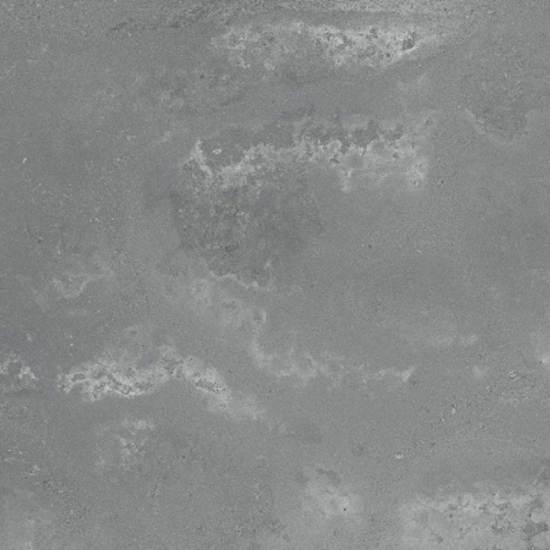

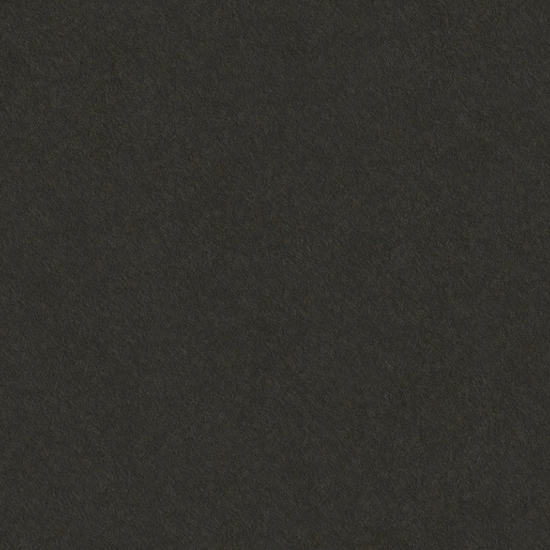

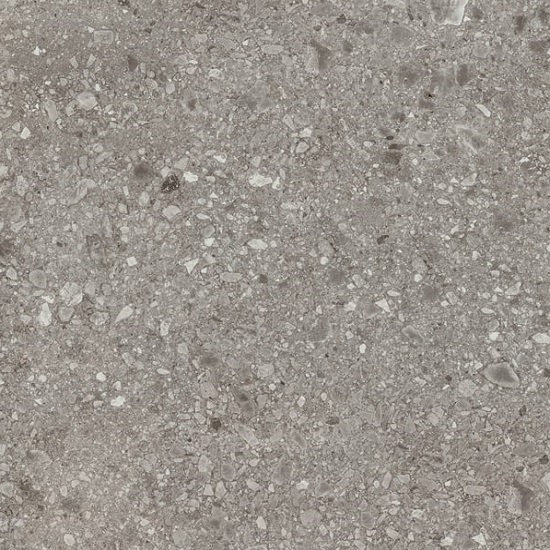

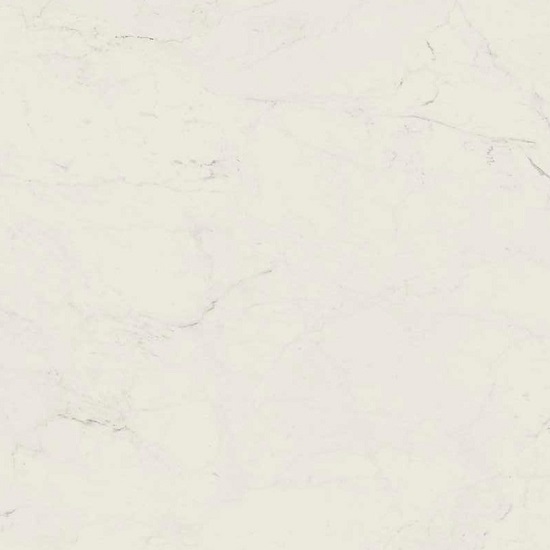

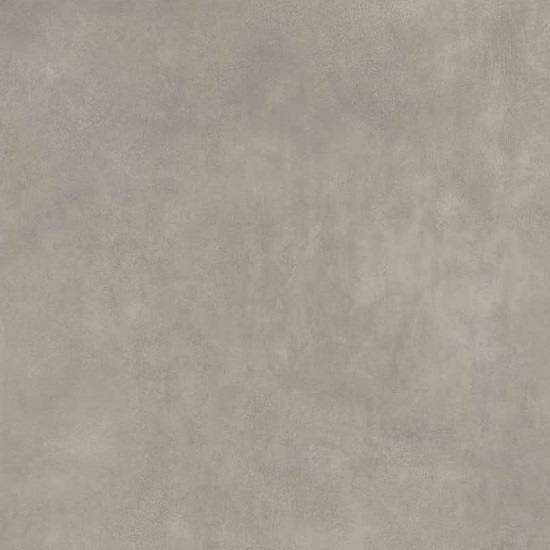

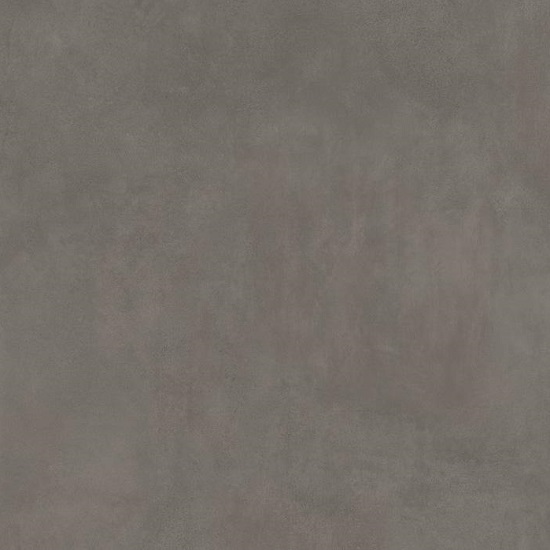

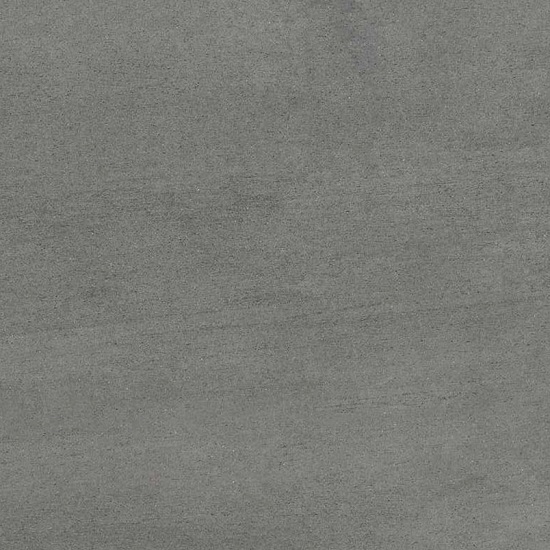

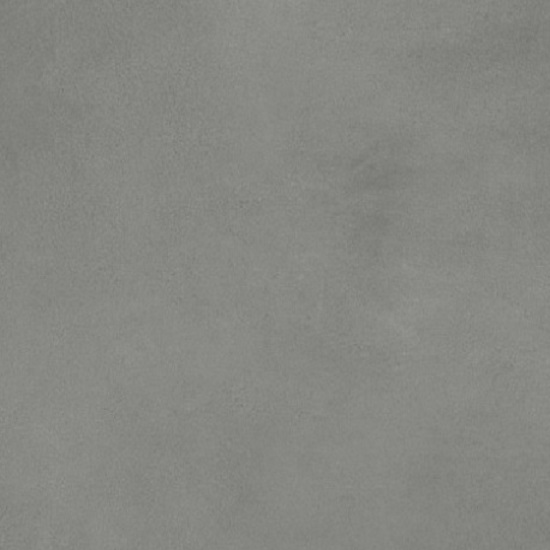

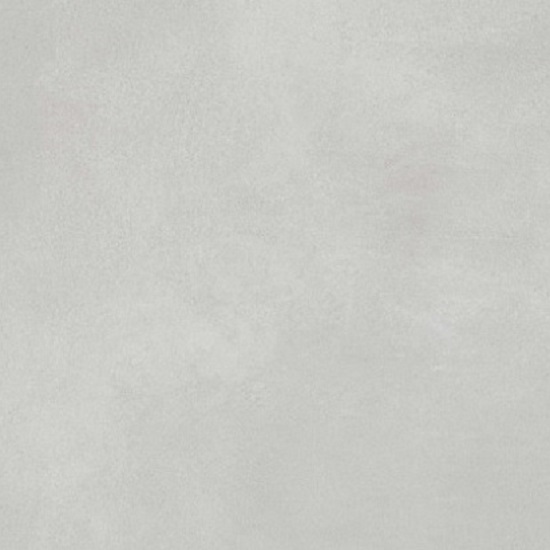

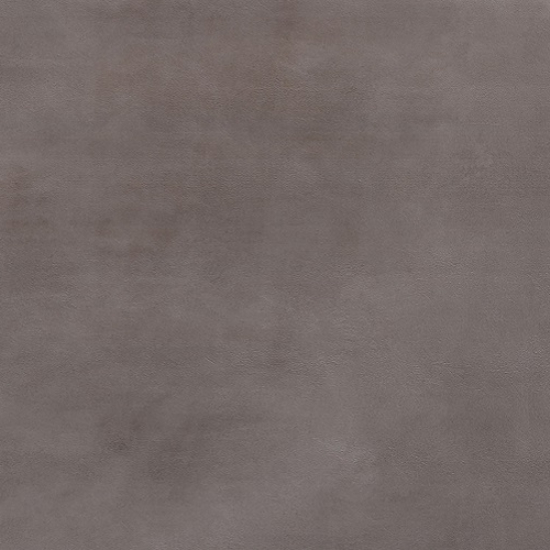

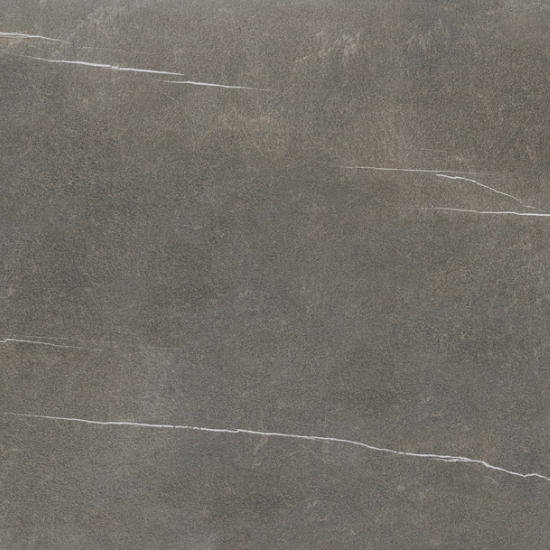

Our Lasa Ceramic worktop by The Top surface boasts unique looks. It effortlessly recreates the beauty of natural materials such as marble, concrete, wood, etc., without the inherent imperfections, flaws or maintenance of the traditional building products.

Lasa By Marazzi: Marble That Won’t Stain In Your Kitchen

The Top Lasa comprises a range of sintered porcelain formulas adhering to a strict environmental policy.

All Marazzi The Top materials include ecological protection and secure and high-quality goods & services supplied throughout their lifespan. These eco-friendly characteristics result from leading decorative and technical research. The company makes surfaces with a low carbon footprint and long-lasting and safe use. In addition, the brand offers guidance for appropriate usage, preservation, and disposal methods.

Marazzi is a leader in the eco-sustainable sector and has contributed to creating ceramic worktops being a locked-cycle process. The brand boasts a system for collecting and reusing rejected products and their raw materials throughout the process. In addition, it applies strict environmental quality criteria throughout the manufacturing phase, limiting natural resource consumption and pollution through the restoration of quarries’ surroundings and grasslands, controlled waste disposal, energy usage optimisation, and industrial wastewater repurposing.

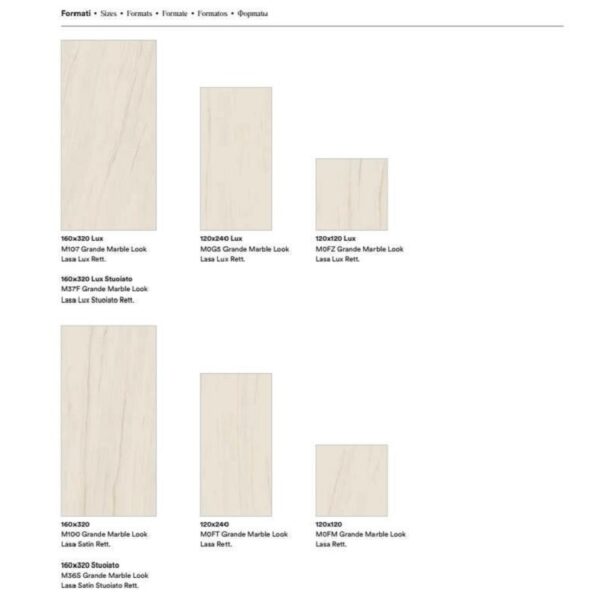

Marazzi Lasa Worktop Sizes, Thicknesses, Finishes

- Slab Size: Marazzi The Top slabs come in 3,200 x 1,600 mm and in sheets of 3,240 x 1,620 mm, to decorate any area of homes and offices whilst avoiding joints and producing a majority of seamless panels. In addition, the lightweight structure makes them easy to install whilst saving costs on transport compared to other stones such as marble and granite.

- Thicknesses: You can choose Lasa Marazzi ceramic in worktop thicknesses of 0.6 cm and 1.2 cm.

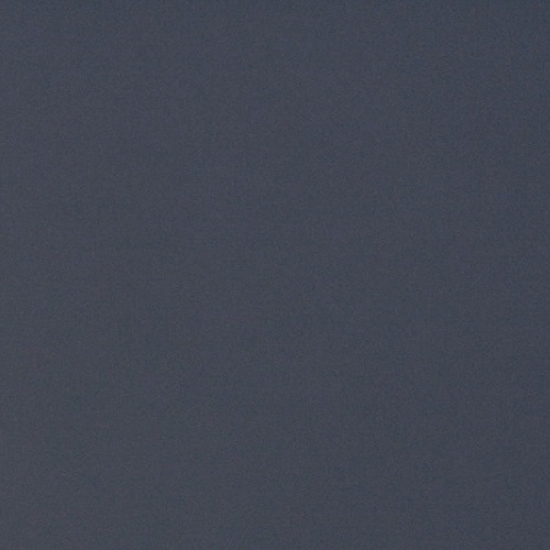

- Finish: Lasa belongs to the MARBLE LOOK Collection, and it is available in sophisticated Polished and Satin finishes.

Marazzi The Top Offers Seven Advantages When Compared to Other Worktops.

- Durability: Marazzi slabs offer a life cycle of approximately 50 years and come with a 25-year manufacturer’s warranty.

- Large Sizes: Its large slab sizes minimise both waste of materials and the number of seams that standard panels may include.

- Non-Porous: It does not absorb liquids, making it perfect for spaces constantly in contact with water.

- Easy to Clean: Use warm or hot water for daily cleaning. If necessary, use a ph neutral detergent.

- Stain-Resistant: Resistant to ketchup, coffee, rust, wine, etc.

- Scratch-Resistant: The Top surfaces boast the highest rating in tests for scratch resistance of their surface.

- High-Heat Resistant: it can tolerate up to 300 Celsius without cracking, burning or scorching.

Caring for Marazzi The Top Work Surfaces

A little bit of hot water eliminates grime and blemishes from the surface and returns it to its original state.

Conventional cleaning

The sintered porcelain worktops do not require any protective coating, and you only need a thorough clean to keep the surface in good condition.

It would be best to clean Marazzi’s worktops with care by washing with hot water and a towel. You can also use neutral detergents when needed. Finally, you can also use Industrial washing machines for expansive areas, with manual finishing.

Getting Rid of Stains and Marks

Using a solvent, you can remove candle wax, rubber, flaxseed oil, silicone, and silicone oils.

Similarly, you can remove concrete, lime bloom, plaster, metal, enamel, and resin residues using an acid cleaner. Acidic cleaners will also remove rust, grout, and emulsion paints from the surfaces. Please check for suitable acid cleansers before application. Finally, an alkaline cleaner will remove stains from beer, wine, coffee, tea, candle wax, vegetable and animal fats, ink, ketchup, mayonnaise, jam, lipstick and other household substances.

Marazzi Surfaces Manufacturing: 200 Metres Long Kiln and Advanced Technologies

The Marazzi Lasa production process comprises 7 (seven) key steps, using an automated factory, and reducing energy consumption:

- Preparation of raw materials: The producer maintains all the natural components separately to minimise cross-contamination. The raw materials are then conveyed through an industrial belt into hoppers and purifying devices.

- Milling and crossbreed: The company takes the formulation from the purification devices or hoppers to a wet milling process, combining the raw materials into specified molecules. This combination is separated until it becomes a stable surface material.

- Colouring: During the pigmentary process, the business employs an intelligent mixer, diluters, and frothers. The mix can merge with the rest of the Marazzi mix, depending on its texture or colour.

- Atomisation: The producer atomises and dries the previously coloured solution, reaching a specific size, grain shape, and humidity level. The various products then stay in different silos.

- Baking of the slabs: During this stage, the producer provides the slab with its chemical, aesthetical, and technical features. It employs temperatures of up to 1300 degrees Celsius, guaranteeing that the various coloured patently. The brand then changes the raw materials and colours into additional temporary substances to complete the process. Finally, the technique uses heat to control these compounds, causing them to interact and follow suitable synthesis methods.

- Finishing the Surfaces: Marazzi uses a low-consumption dryer, waiting up to 48 hours for the slabs to solidify. In addition, it uses high-resolution digital printing to recreate the original look of different building and decoration materials. Finally, the company uses post-fire industrial surface finishers. It achieves the different textures it provides to the materials before going through a strict quality control method.

- Storage: Using automated packaging, the brand reduces health and safety concerns for its team and contributes to a closed cycle of eco-sustainable production.

12 Benefits of Marazzi Lasa Worktops

Marazzi porcelain countertops include all the performance attributes to transform any area of a home or office into a sophisticated space, be it indoors or outdoors:

- Eco-friendly

- Anti-warping

- Non-absorbent

- Frost resistance

- Scratch resistance

- Easy care & cleaning

- Heat & fire resistance

- Made with raw materials

- Thermal shock resistance

- Impact & abrasion resistance

- Highly stain and acid resistant

- Resistant to household chemicals

Marazzi The Top uses different formulations according to the colour and finish of the products of choice, without compromising on its superior performance features.

TECHNICAL CHARACTERISTICS

| Technical Features | Method Test | Average Typical Value | Result | |

|---|---|---|---|---|

| Dimensions (thickness & flatness) | ISO 10545-2 | ± 0,5% / ± 2 mm | compliant | |

| Appearance | ISO 10545-2 | ≥ 95% | UNI EN 14411-G | ≥ 95% |

| Modulus of rupture | ISO 10545-4 | N/mm2 | ≥ 35) | |

| Breaking strength | SO 10545-4 | N | ≥ 1300 | |

| Impact resistance | ISO 10545-5 | Declared Value | 0,85 | |

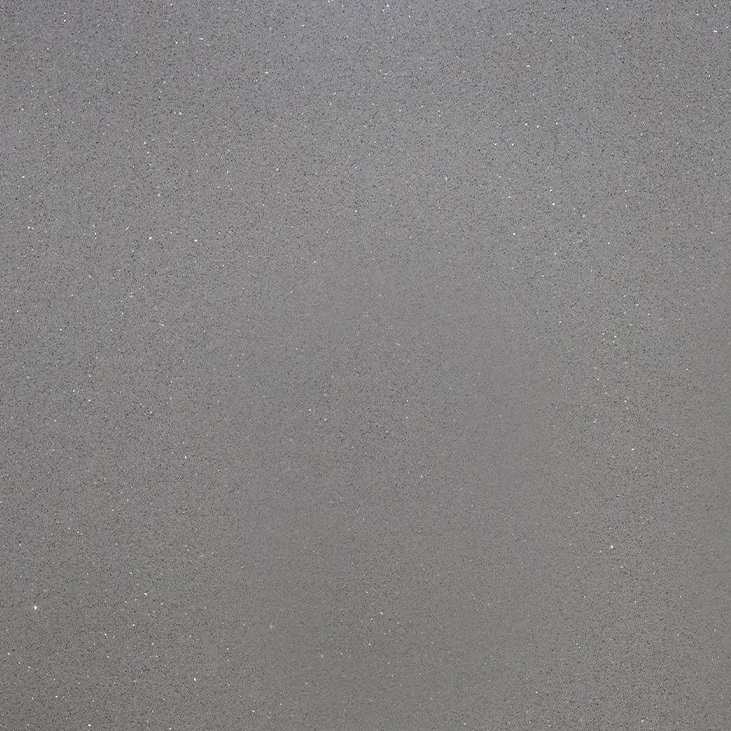

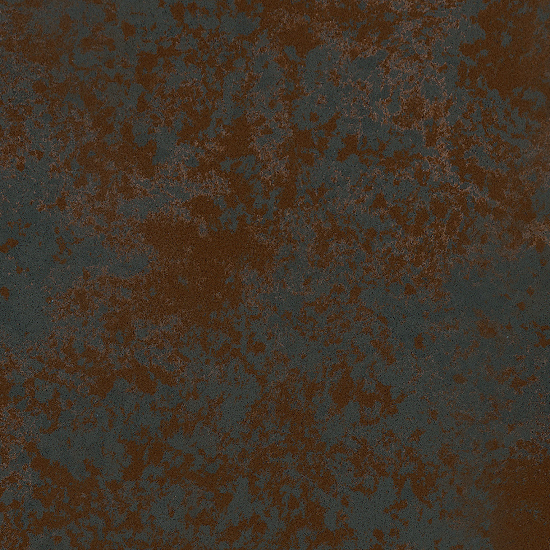

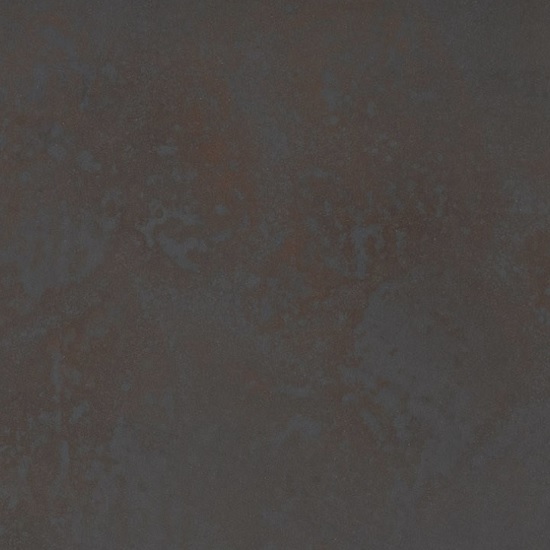

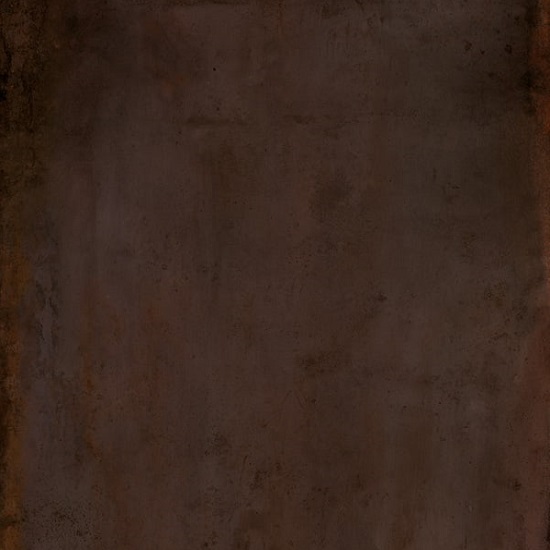

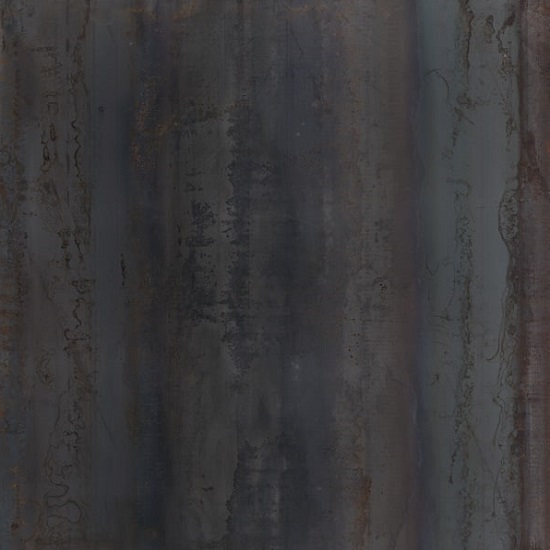

| Abrasion resistance | Internal Class | Concrete look, metal look, satin | Class H | |

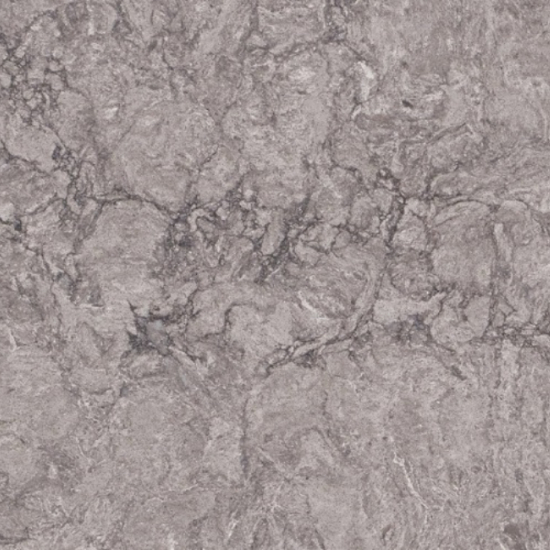

| Abrasion resistance | Internal Class | Marble Look Satin, Stone Look | Class G | |

| Abrasion resistance | Internal Class | Marble Look Lux, Solid Color Lux | Class F | |

| Resistance to deep abrasion | ISO 10545-6 | mm3 | 120-150 | ≤ 175 |

| Frost resistance |

ISO 10545-12 | Compliance | Test passed in accordance with the EN ISO 10545-1 standard |

|

| Thermal shock resistance | ISO 10545-9 | Compliance | Test passed in accordance with the EN ISO 10545-1 standard. |

|

| Linear thermal expansion coefficient |

ISO 10545-8 | x10 -6/°C | ≤ 9 | |

| Stain resistance |

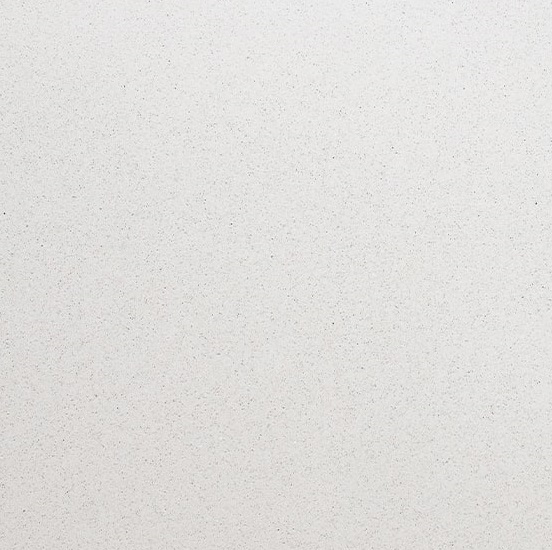

ISO 10545-14 | Concrete Look, Metal Look, Solid Color Satin |

Class 5 | |

| Stain resistance |

ISO 10545-14 | Marble Look Satin, Stone Look | Class 3 | |

| Stain resistance |

ISO 10545-14 | Marble Look Lux | Class 3 | |

| Stain resistance |

ISO 10545-14 | Solid Color Lux | Class 3 to 5 | |

| Resistance to chemicals for household use and swimming pool salts |

ISO 10545-13 | Minimum Class B | Concrete Look, Marble Look, Metal Look |

Class A |

| Resistance to chemicals for household use and swimming pool salts |

ISO 10545-13 | Minimum Class B | Solid Color, Stone Look | Class A |

| Resistance to acids and bases | ISO 10545-13 | Declared value | LA-LB HA-HB |

|

| Release of dangerous substances | ISO 10545-13 | mg/l | Declared value | 0 |

| Contact with food | UNI EN 1186:2003 | mg/dm2 | 0 | |

| Colour resistance to light exposure | DIN 51094 | UNI EN 14411-G | Compliant | |

| Apparent density | ISO 14617-1 | Kg/m3 | 2500 | |

| Deep abrasion | ISO 14617-4 | mm | 24-27 | |

| Freeze-thaw resistance | ISO 14617-5 | None | ||

| Thermal shock resistance | ISO 14617-6 | None | ||

| Impact resistance | ISO 14617-9 | Joules | 3J | |

| Volatile organic compound emission test |

ISO 16000-9 | Class A | ||

| Resistance to cold liquids | EN 12720:2013 | CEN/TS 16209 | Class A | |

| Resistance to damp-heat | EN 12720:2013 | CEN/TS 16209 | Class A | |

| Resistance to dry heat | EN 12720:2013 | CEN/TS 16209 | Class A | |

| Dirt retention | EN 9300:2015 | No visible changes | ||

| Resistance to fungi | ASTM G 21 | No fungi growth |

Marazzi The Top: 25-year warranty

Marazzi's warranty is valid for 25 years from the product's date of purchase/delivery, understanding its manufacturing and technical traits and attributes.

You can use Marazzi Products in any residential application.

You must activate your Marazzi The Top warranty within 2 (two) months o purchase by presenting your purchasing invoice and filling in a warranty form here.

The Top by Marazzi porcelain worktops comprises ceramic clay and mineral colouring instead of resin colouring in other countertops. As a result, it makes them more robust (40% stronger than marble), less prone to staining ( < 0.50% liquid absorption), and offers heat resistance (it melts at over 2000 Celsius) than other work surfaces such as quartz.

Have you got 1 minute? -The below video shows you Marazzi's manufacturing plant, and its highly automated production process:

These are three main steps for cutting ceramic worktops by Marazzi:

Preparation

- Remove at least 2 cm of Marazzi The Top from each slab edge.

- Plan a sequence that detaches the worktops or panels from the slabs and then makes the cutouts.

- Allow for a minimum 5 mm radius, ensuring the surfaces are flat, level and stable whilst cutting.

Cutting holes

- Mark the cutting point, no more than 5 cm from the slab edge, coring at 75 degrees. You can use a flared drill bit for more even borders.

- Cut along the marking with an angle grinder with a diamond disc.

- Smooth the cutout's edges with diamond polishing pads containing velcro backers

Cutting edges

To create Marazzi worktop edges, follow the below steps:

- First, use a diamond tool device to shape the 45 degrees angle mitred edges.

- Score the slab without stopping with constant speed and pressure to cut straight edges.

- To detach the scored areas, detach the pieces using cutting pliers at both ends.

- You can use a drill or angle grinder containing a diamond disc or a 6-8mm drill to cut rectangular shapes. Them, cut along with the device comprising the diamond bit or drill.

- Shape the edges using a machine fitted with diamond tools.

The below video shows you Marazzi The Top cutting process for creating cutouts and edges:

To install Marazzi The Top worktops, make sure the surfaces are clean. Then, ensure that the substrate (kitchen units, bathroom cabinets, etc.) is level and flat.

Reinforce the cutouts and other weak points in the worktops.

- First, prepare the adhesive, and place it evenly across the substrate and on the worktops.

- Gently put the panels over the cabinetry during assembly, ensuring aligned joints.

- Allow a minimum 2mm joint, using packers and clamp levellers where required.

- Once the worktops are in place, mix the grout to colour-match it to the tone of the worktops.

- Remove any excess grout with plenty of water and clean in diagonal motions.

- Once the worktop installation is complete, clean all the surfaces thoroughly with a window glass cleaner. Finally, dry with a microfibre cloth.

If you have 90 seconds to spare, you can watch the visual guidance below:

Marazzi porcelain worktops require little to no upkeep. You can clean the surfaces using clear water or a neutral pH cleanser. To keep your surfaces from becoming dull, rinse with water and dry with a cloth. Clear spillages immediately to avoid stains on light-coloured worktops. You don't need to seal or acid-clean Marazzi The Top surfaces.

Unlike standard ceramic or porcelain, made by fusing clay minerals and other ingredients, Marazzi The Top is a Sintered Stone because it uses different raw ingredients. In addition, each Sintered Stone company has its particular method that includes different heating temperatures, substances, and effects. And Marazzi the Top uses materials that contain elements that provide different effects and finishes than those on standard ceramic or porcelain.

As a result, Marazzi continues creating new material categories and product ranges. These include Ultracompact surfaces, large panels, extra-large slabs, and compact surfaces.

Even though Marazzi The Top is more expensive to buy than other the more common natural stone and quartz, it does not require upkeep. It is an essential element since it enables Marazzi to be incredibly cost-effective throughout time. Furthermore, it provides a 25-year available warranty, increasing the property's total worth.

It is not easy to scratch Marazzi The Top. For example, kitchen worktops, lobby, and shop floors are the most demanding applications for decoration surfaces. Marazzi The Top results 'Class A', CEN/TS 16209, during testing method EN 15186:2012 met B, making it ideal for such applications due to its resistance to wear and tear.

No. Although the chipping potential of Marazzi The Top is lower than that of other surface materials, it is stiffer than marble and quartz, making it more susceptible to chipping than these materials.

If you live in London or up to 100 miles from it, you can get Marazzi The Top samples here. The team at the Worktop Library will get Marazzi samples delivered to your door between 2-3 business days.

Marazzi boasts five production plants in Italy, Spain, the USA, Japan, and China. In addition, Marazzi produces The Top worktops for the UK and Europe in two places:

- Marazzi Headquarters & Plan, Viale Regina Pacis 39, Sassuolo, Italy

- Marazzi Iberia S.L.U., Avenida Enrique Gimeno 37, 12006, Castellon, Spain

Marazzi The Top is an excellent material for fire hearth and chimney exterior cladding. Its thermal expansion of x10 -6/°C, enabling you to limit the number of joints to a minimum.

You can use Marazzi The Top surfaces in applications such as the front or side of chimneys protected from the heat by an interior resistant wall. However, the company does not advocate its usage within pipes. It is because of the risks of abrupt changes in conditions or temperature.

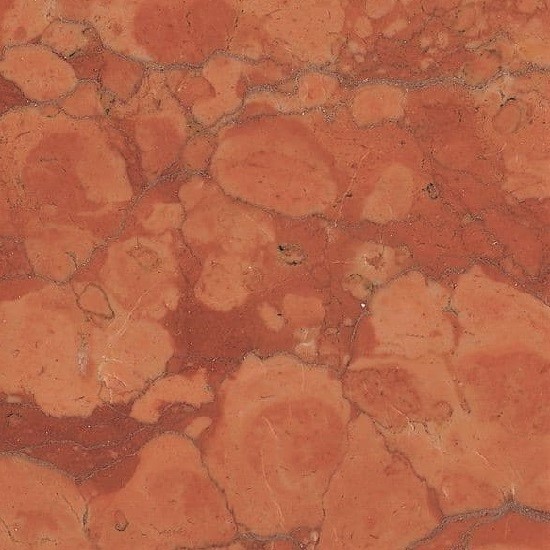

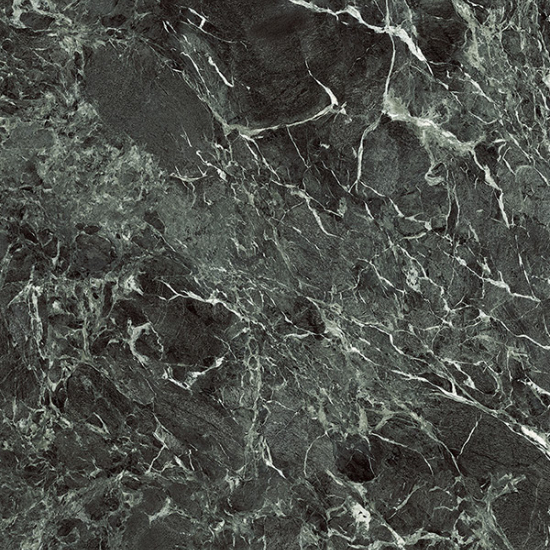

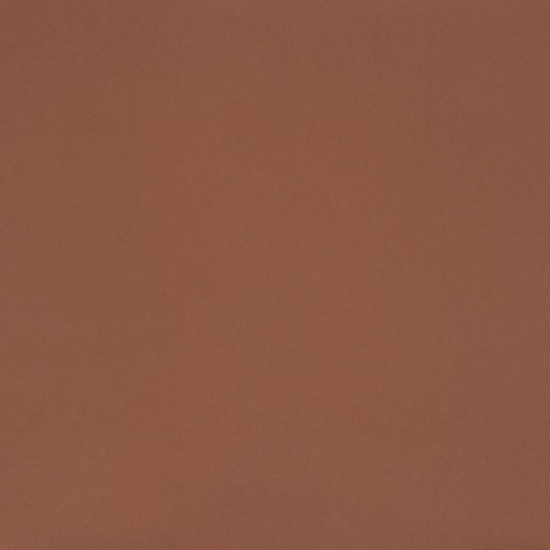

Marazzi The Top surfaces are ideal for outdoor use and offer unmatched UV rays resistance. You can install them on concrete, elevated floors, stone, sand, or lawn. They are available in different colours and textural finishes, with the appearance of marble, concrete, terracotta, wood, stone, and other traditional decoration materials.

Marazzi The Top has a modulus of rupture of a minimum value of 32 N/mm2 (ISO 10545-4). As a result, it creates enough flexibility in the stone, letting you construct curved upstands, curved breakfast bars, circular kitchen islands, and other specific curved designs.

Marazzi The Top countertops are available in three different thicknesses: 6 mm, 12 mm, and 20 mm. However, not all colours come in all three thicknesses.

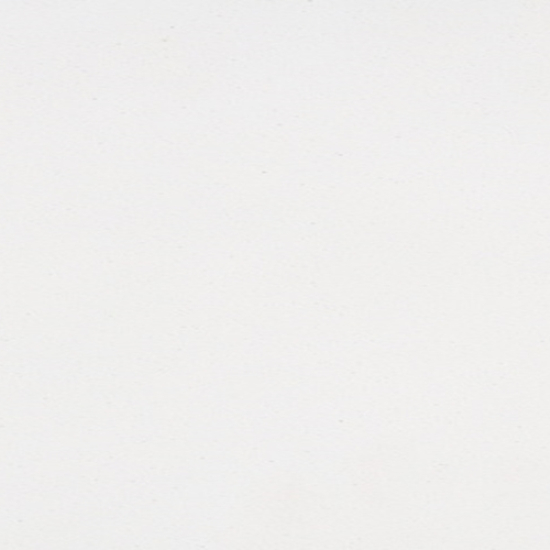

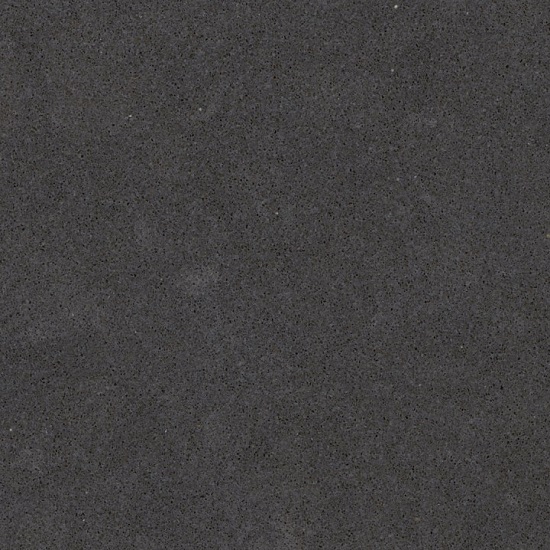

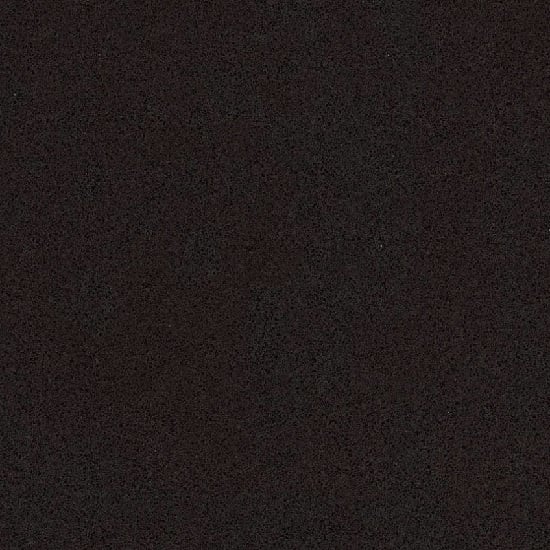

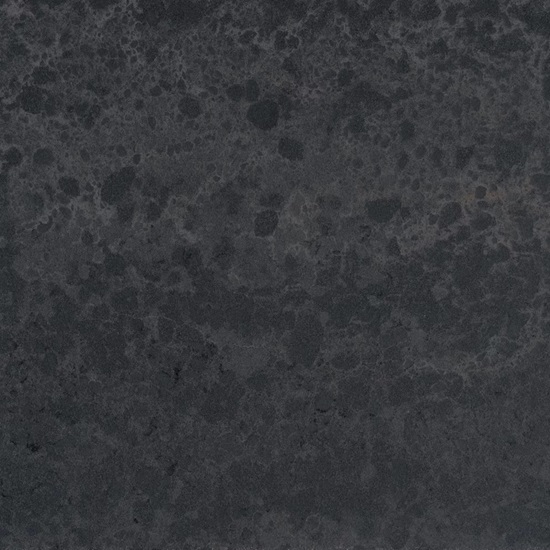

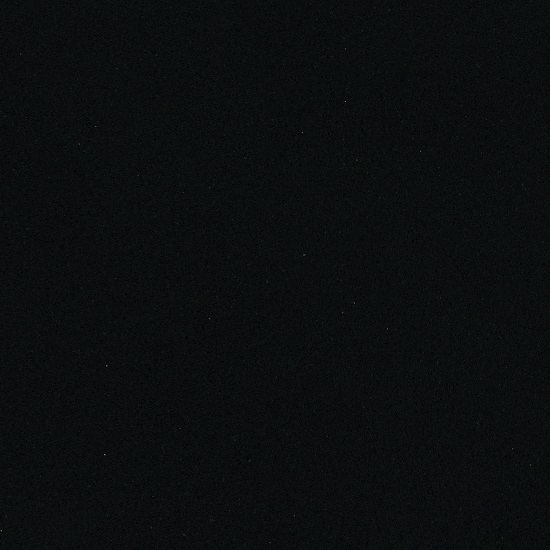

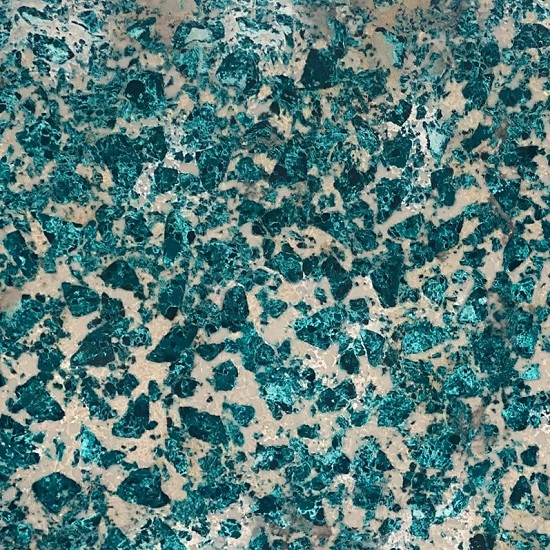

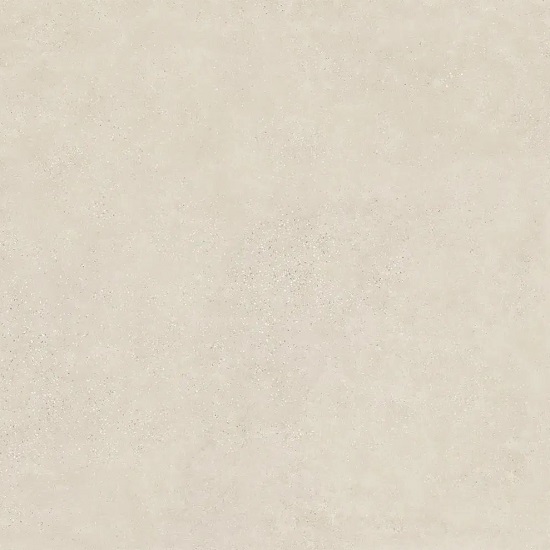

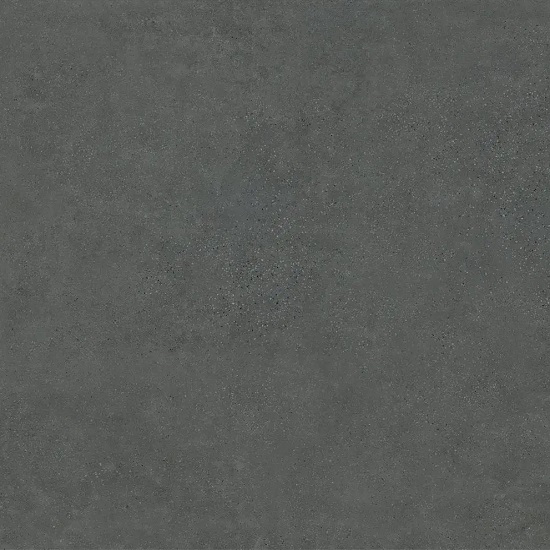

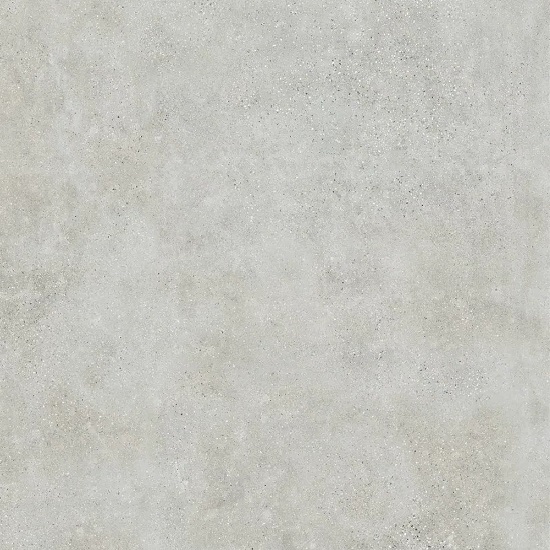

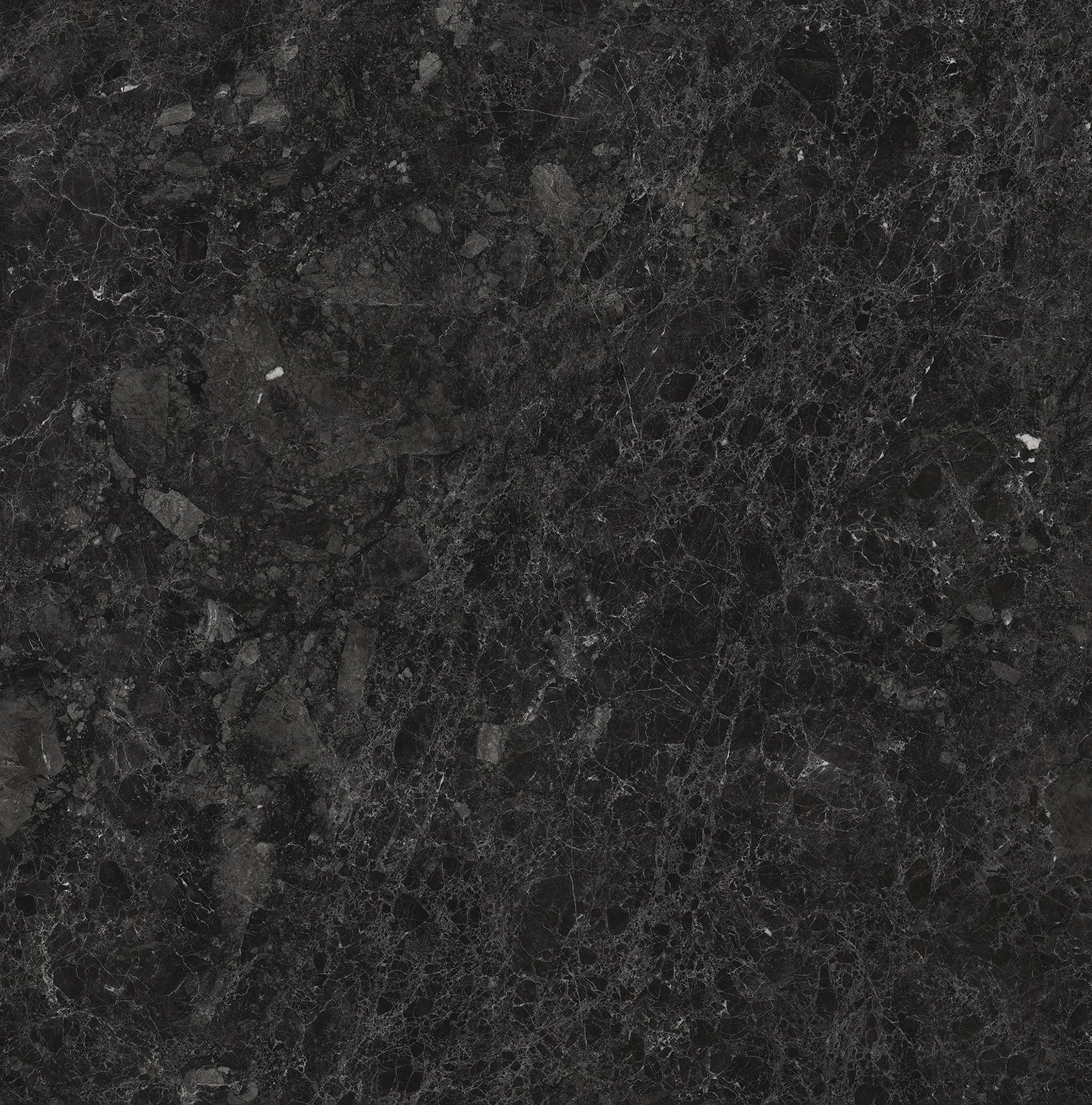

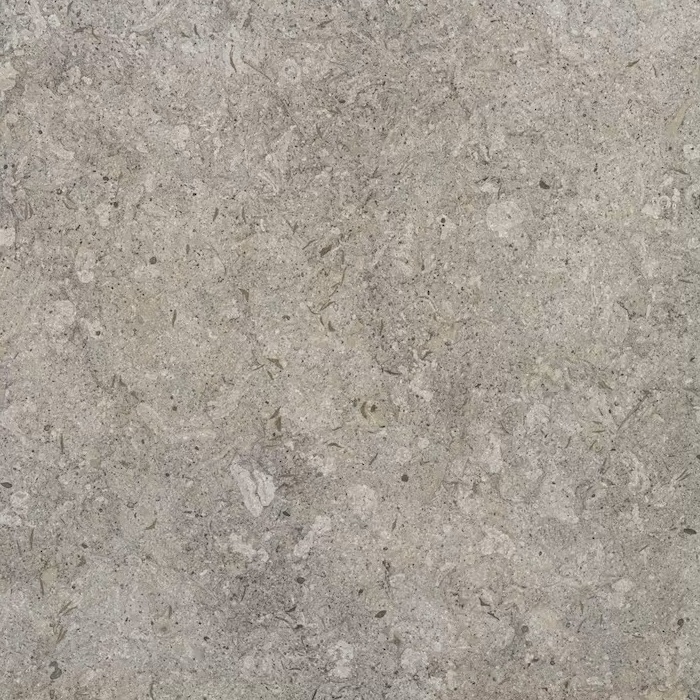

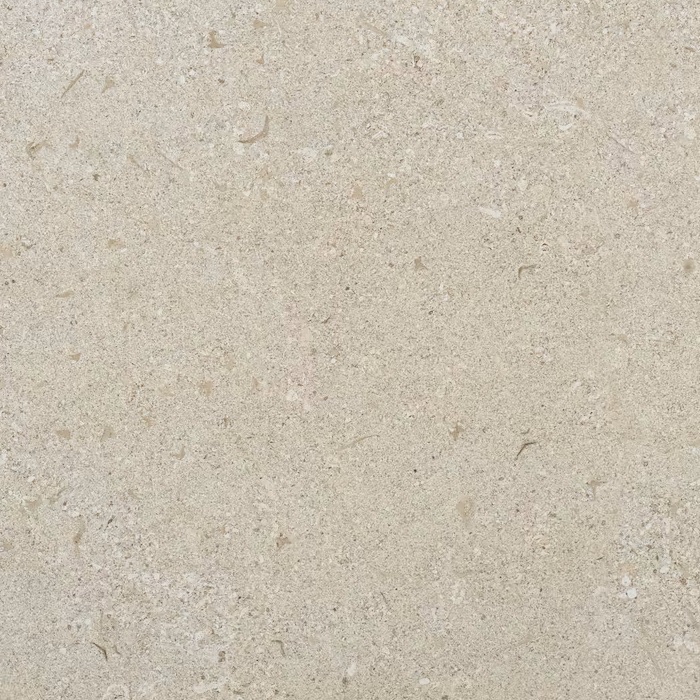

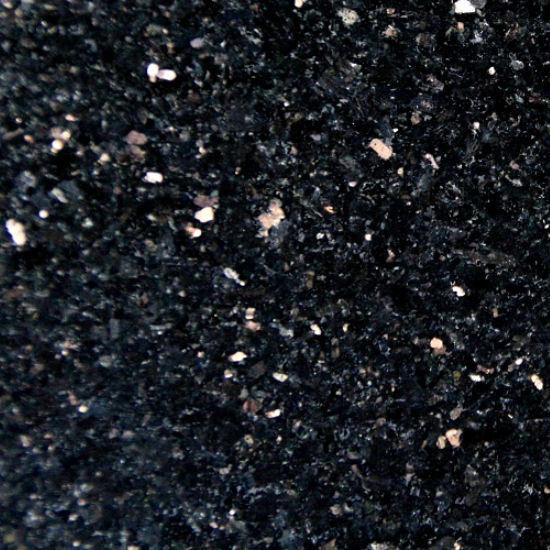

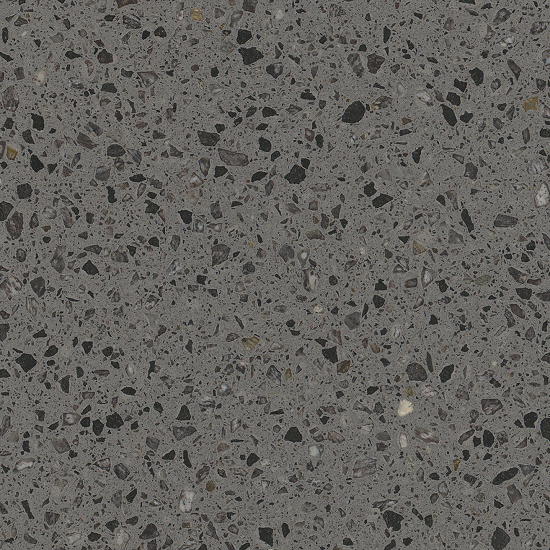

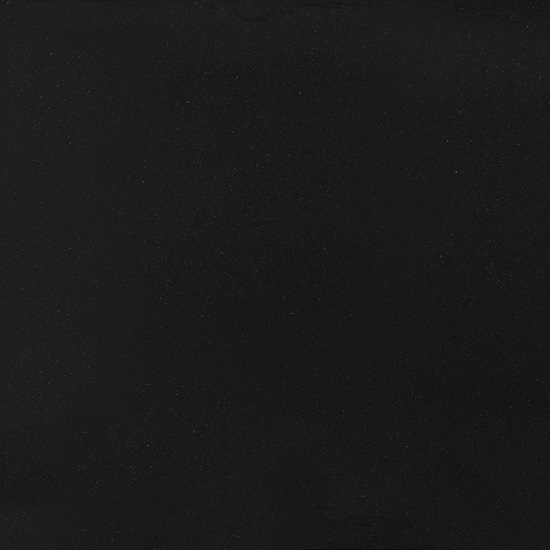

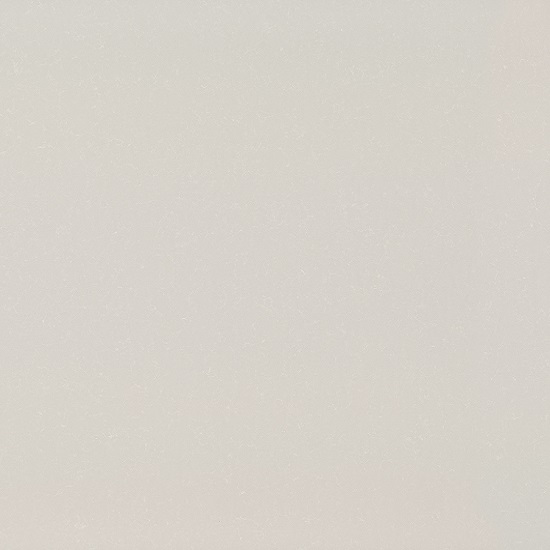

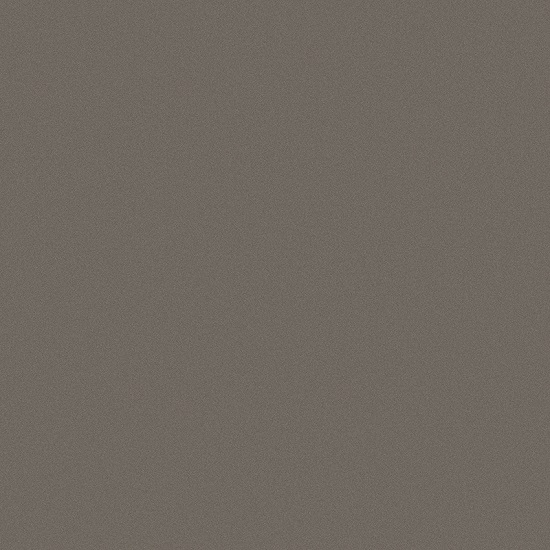

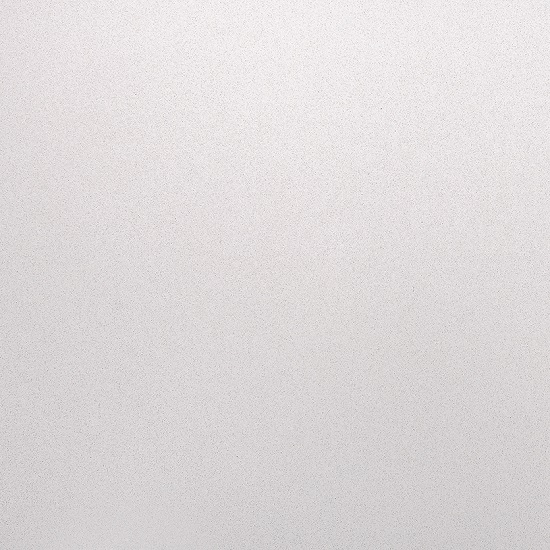

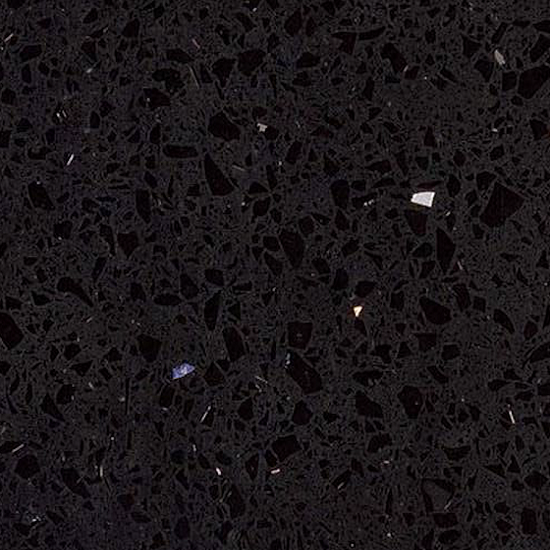

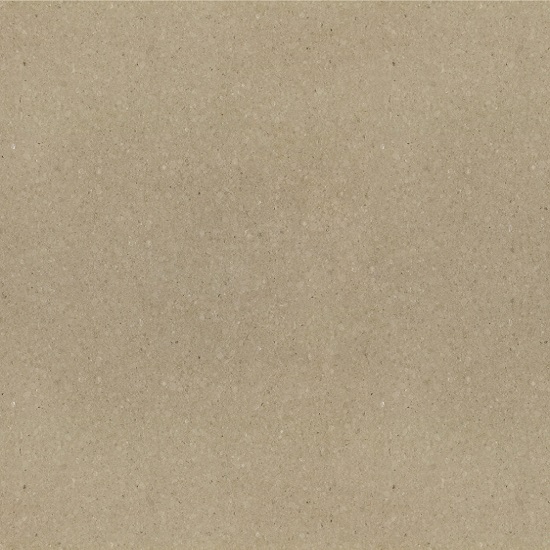

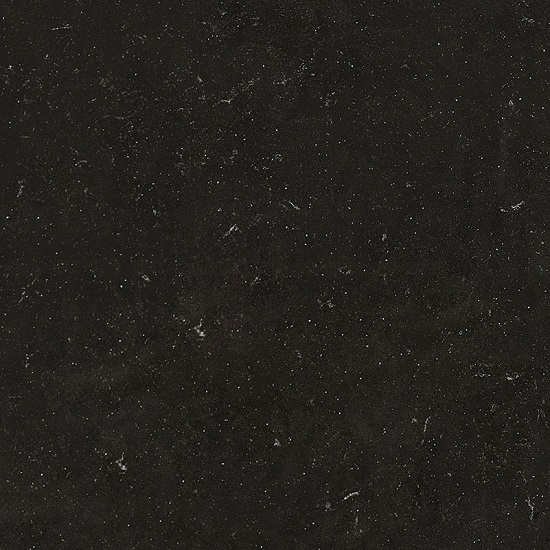

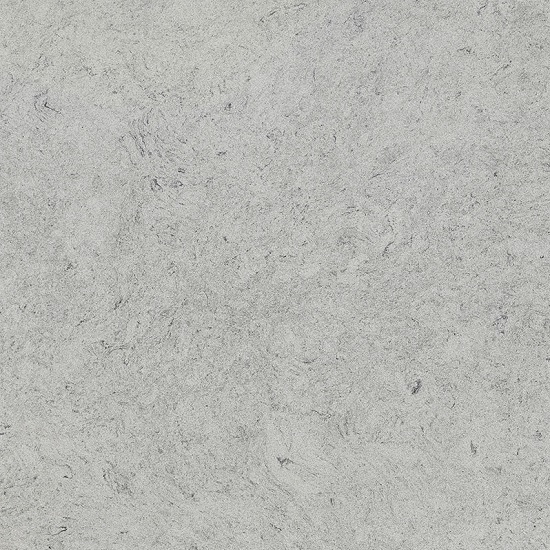

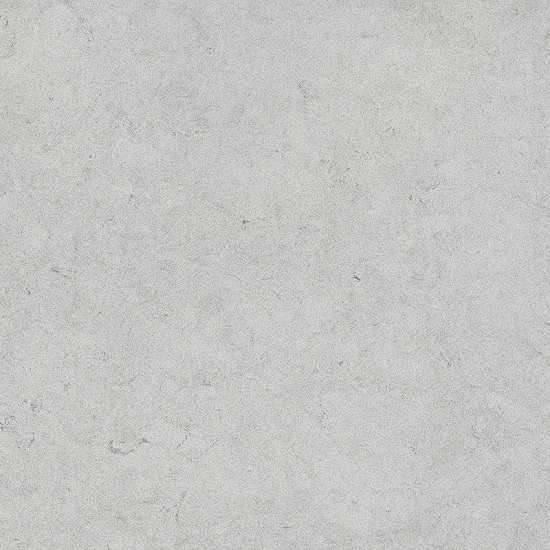

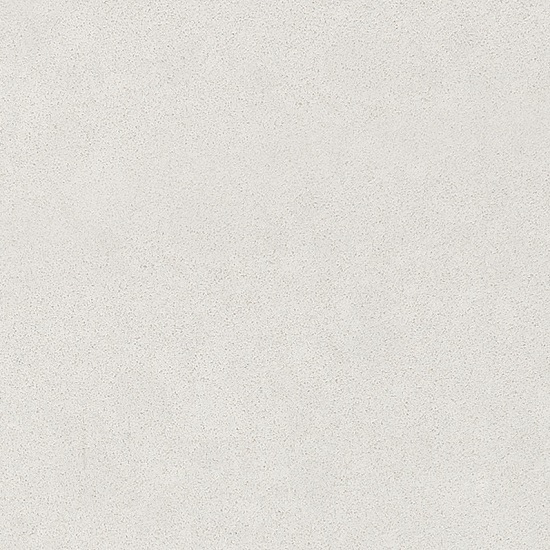

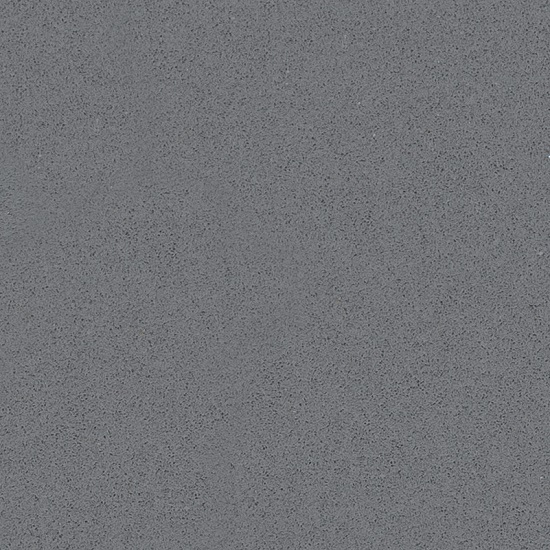

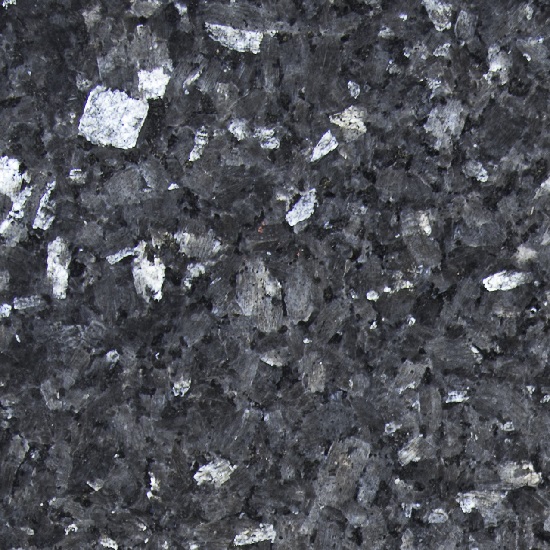

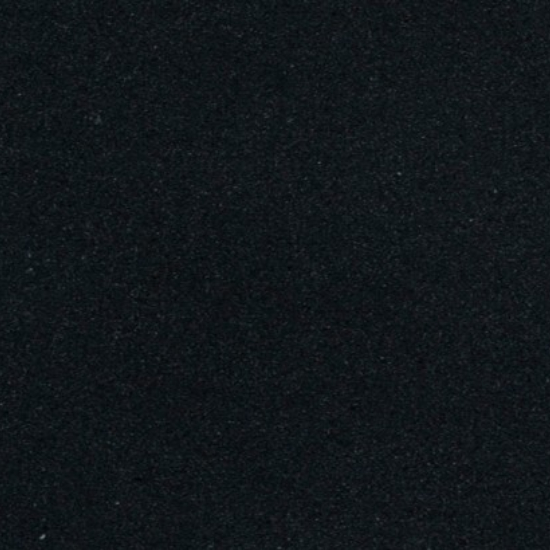

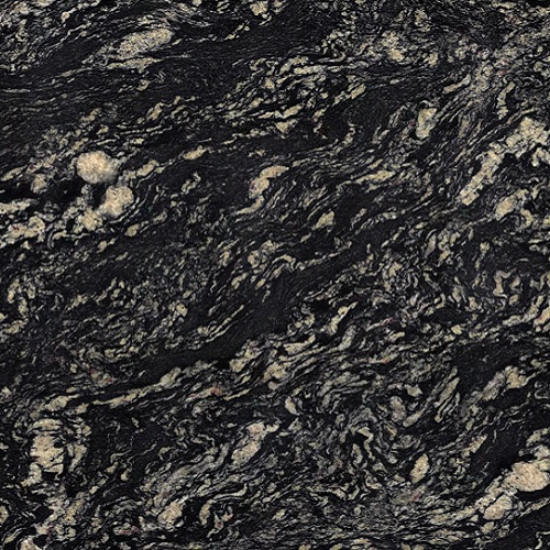

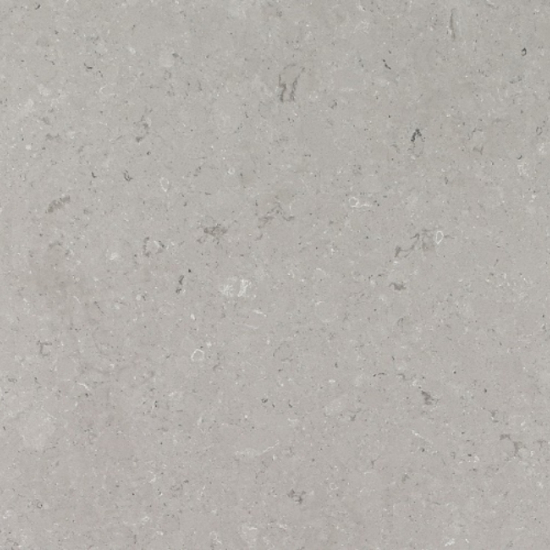

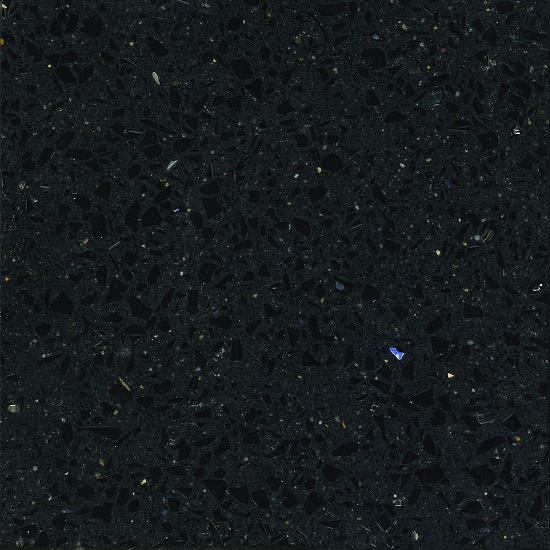

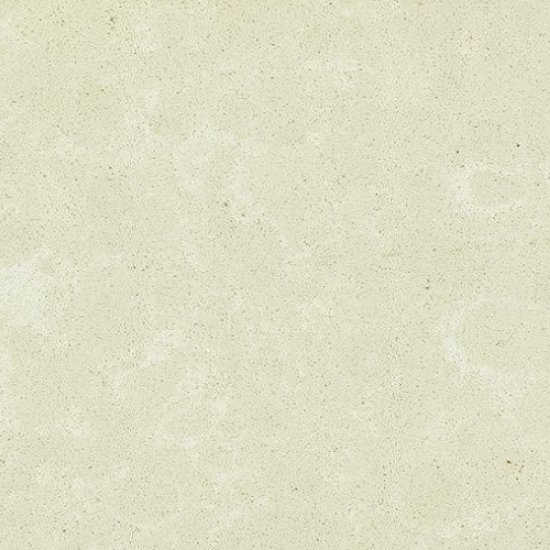

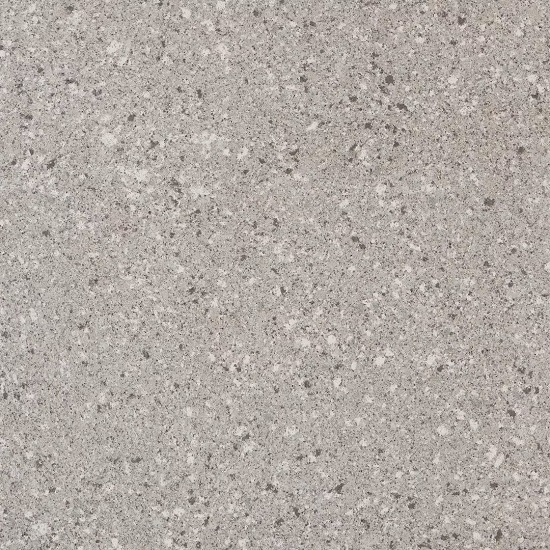

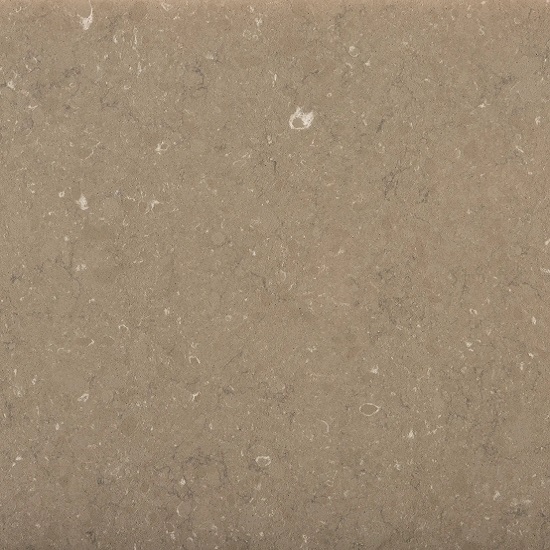

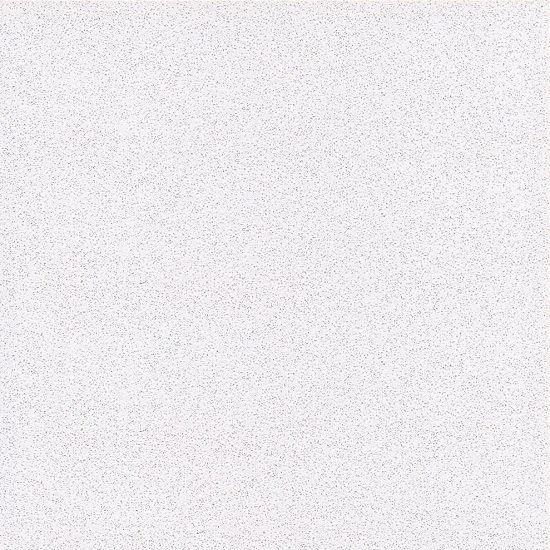

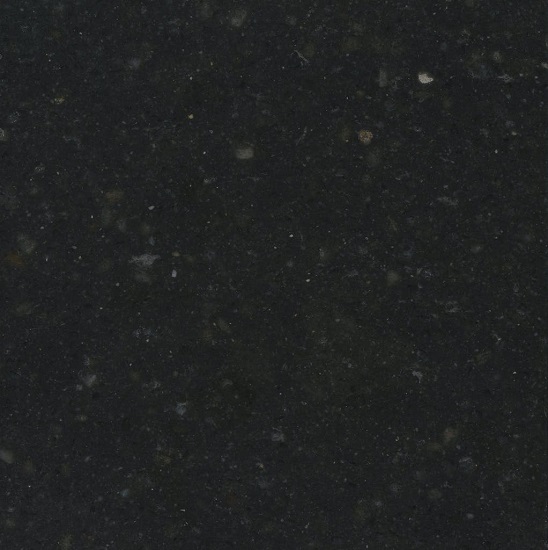

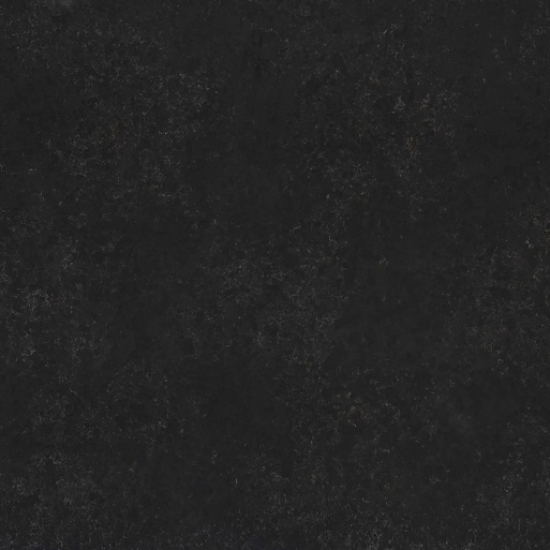

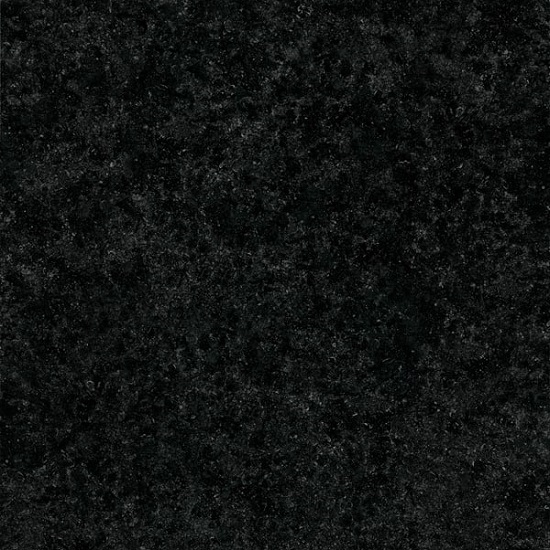

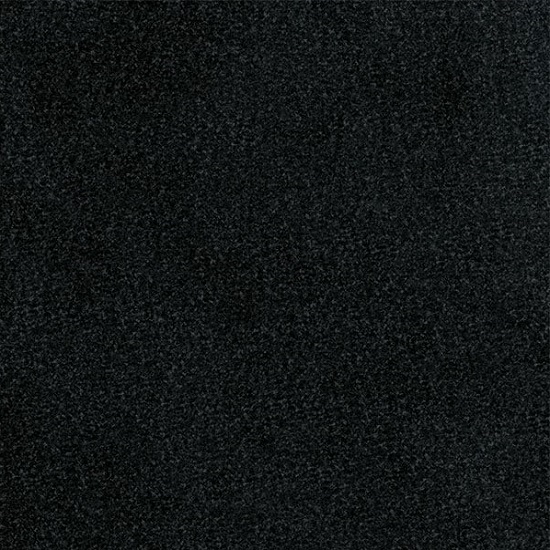

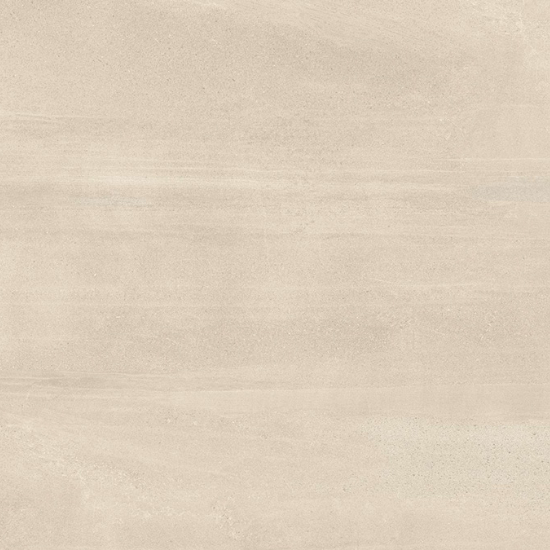

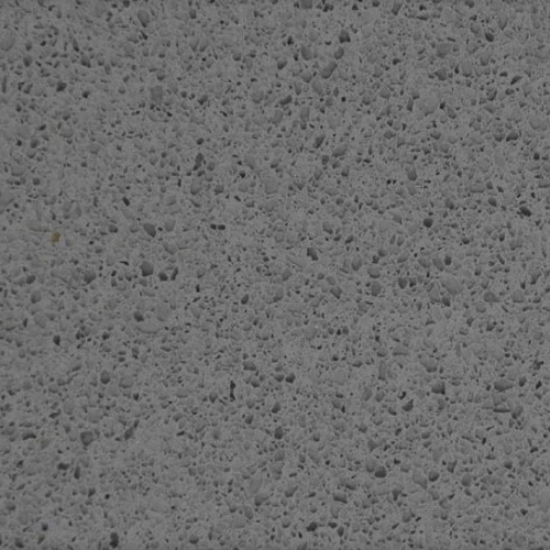

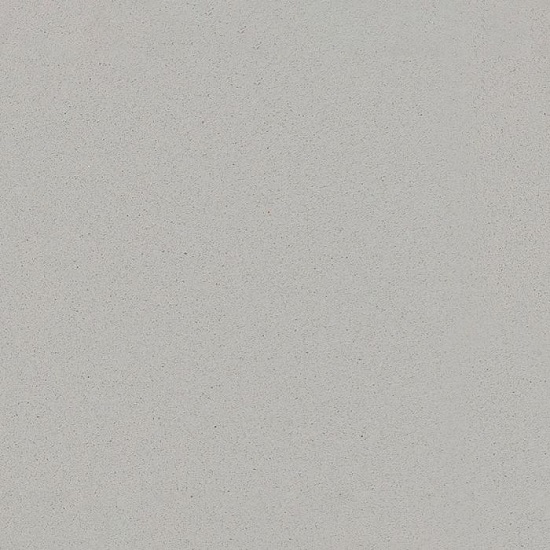

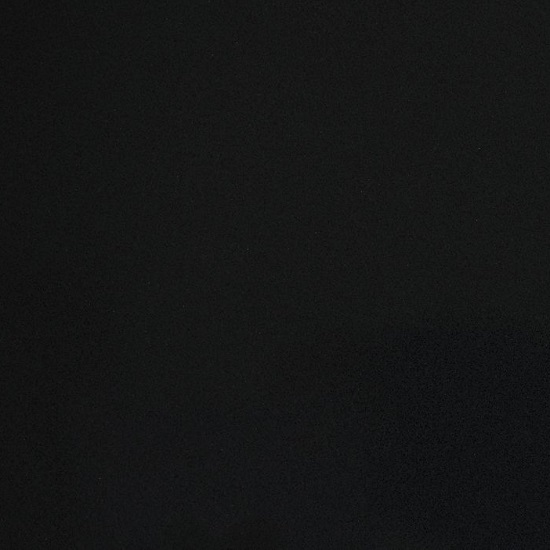

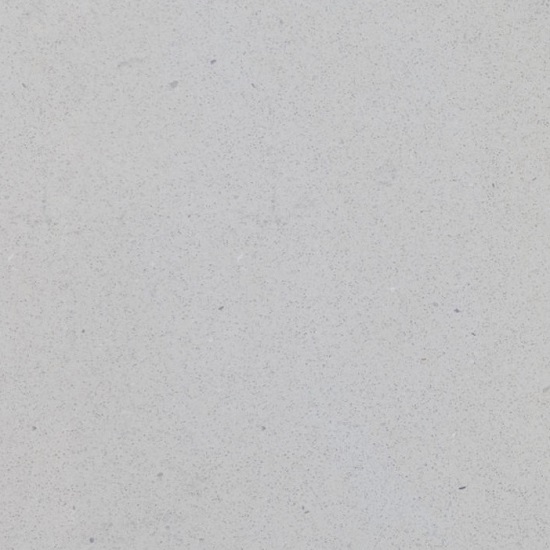

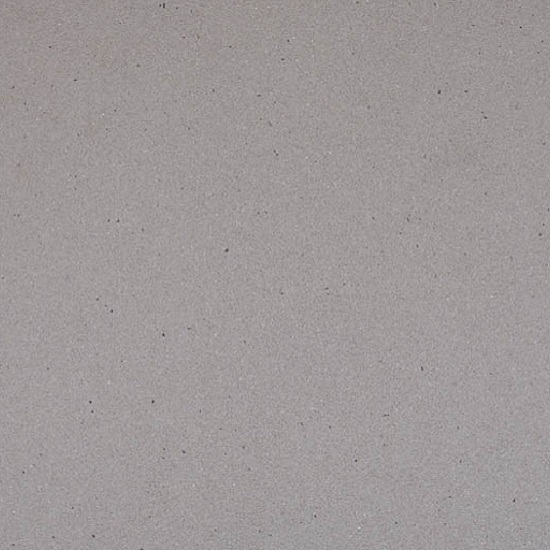

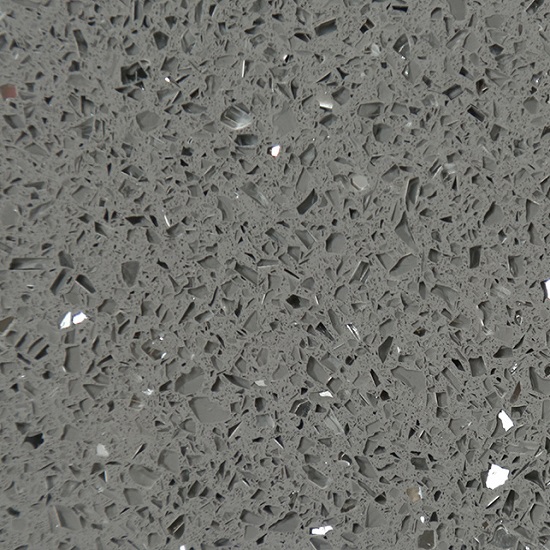

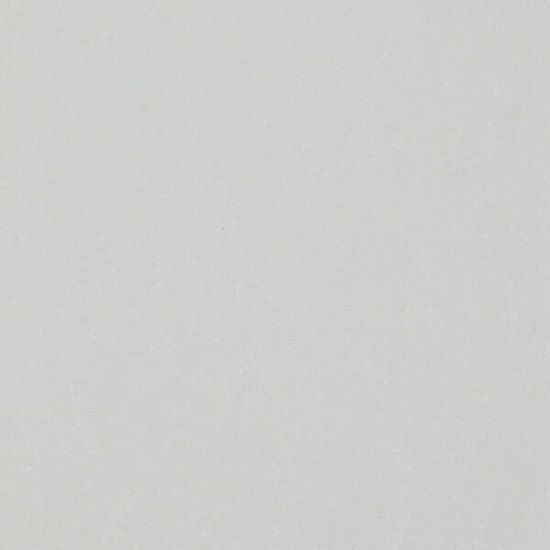

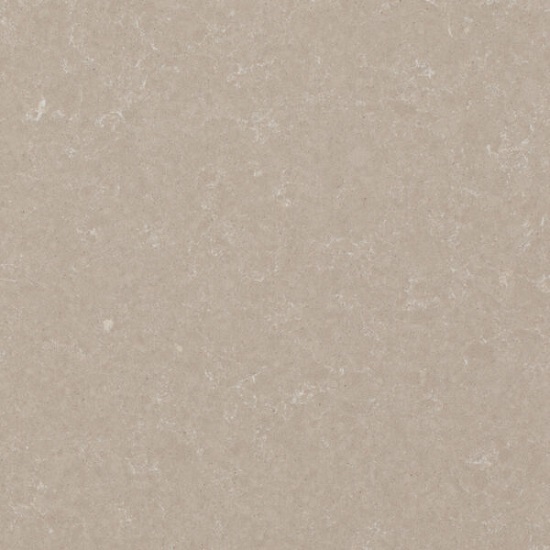

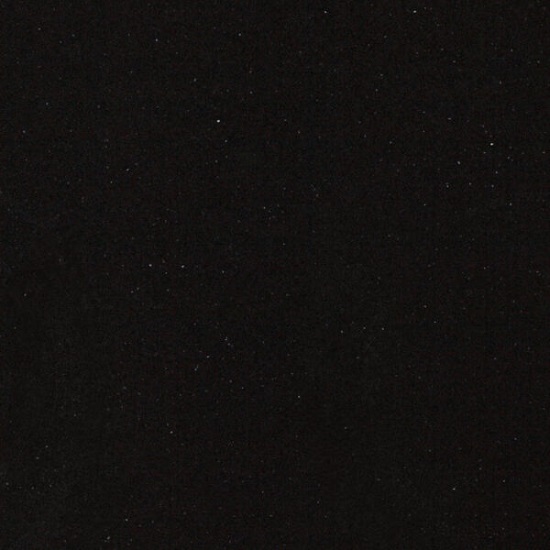

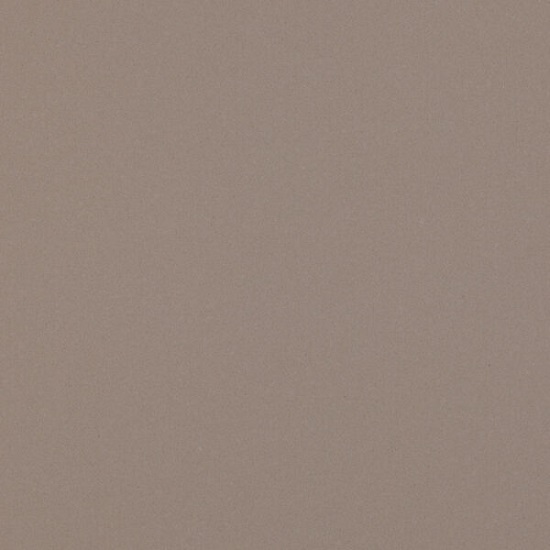

The Marazzi The Top colours you can choose from these three different thicknesses are Statuario, Solid White, Solid Black, Granito Black, Limestone Sand, and Porfido Greenery. Then, there are 42 Marazzi. The Top colours are available in thicknesses of 6 mm and 12 mm, 6 mm and 20 mm, or 12 mm and 20 mm.

You can check which colours are available in each thickness by using our product filter selectors.

When comparing Marazzi The Top to quartz, the two significant distinctions are that Marazzi The Top surfaces are more heat resistant than quartz (up to 300 Celsius vs 150 Celsius for quartz). In addition, you can use Marazzi The Top outside because it does not include the polymers that degrade the colour of the quartz surfaces when exposed to direct sun for long durations. However, one disadvantage of Marazzi The Top worktops versus quartz is that the material has a more stiff layer, increasing the susceptibility to chipping when a strong impact happens (on its borders and corners), even though Marazzi The Top is still difficult to chip.

No, Marazzi The Top is a new type of porcelain known as a sintered stone, available in extra-large slabs. It differs from ceramic in terms of the raw materials in its construction, its production procedures, and the finishes and effects it provides.

If a grout mist remains on the worktop's surface, it may look dull. It is common when the grout is not entirely removed from the worktop's surface shortly after installation. Because grout is a type of concrete, it becomes difficult to remove once completely dried.

To recover the surface's lustre:

- Apply CIF cream to a small testing area.

- Mix it with warm water and leave the solution to rest for one minute.

- Rinse with plenty of warm water.

In addition, natural wear and tear can cause scratches, which hold dirt and diminish lustre over time. For example, sand or gravel attached to tools you repeatedly push across a worktop. Abrasive-finished children's toys, heavy trolleys or dragging heavy tools and appliances can also scratch the worktops.

RETURNS AND SHIPPING POLICY RETURNS

Except for damaged surfaces, all sales are final. Please call 020 39760029 or email [email protected] for more information before mailing exchanges or online purchasing return products installed in faulty or damaged condition.

SHIPPING \ TURNAROUND

We process all orders within one business day. However, specific stones may have longer lead times due to high demand or special-order items from other countries.

DELIVERY & INSTALLATION COSTS

We compute delivery and installation costs at the time of purchase. Our team of professional stone fitters install all stone surfaces.

Installation and delivery charges vary depending on weight, site access, and delivery location from our workshop in West London, United Kingdom.

INSTALLATION & DELIVERY ADDRESSES

Stone worktop installation is available in London and 150 miles surrounding areas. Don't hesitate to get in touch with our Worktop Library Service Team at (20) 39760029.

Reviews

There are no reviews yet.